Coating process for applying water paint to elevator door and door pocket sheet metal parts

A coating process and technology for sheet metal parts, applied in electrolytic coatings, devices for coating liquid on the surface, coatings, etc., can solve the problems of uneven paint film, low coating efficiency, large overspray, etc., and achieve Coating production height, improvement of product quality and production efficiency, effect of coating production automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

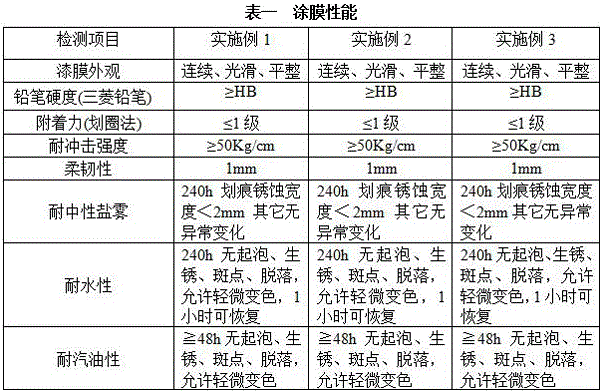

Examples

Embodiment 1

[0021] (1) Pre-treatment: Spray pre-degreasing for 1 minute and degreasing for 5 minutes on the surface of the elevator door and door cover sheet metal. The construction method is spray, the spray pressure is 0.1MPa, and the working temperature is 55±5℃. Alkalinity at 25pt. Then perform the first water washing in the water washing tank, that is, spray and wash with deionized water for 2 minutes, and wash away the residue after the degreasing treatment on the substrate. Then use a surface conditioner with pH=8 for surface adjustment, and then use a phosphating solution with a total acidity of 20pt, a free acidity of 0.8pt and an accelerator concentration of 3pt to phosphate the substrate for 5 minutes. The phosphating process uses spraying In this way, a uniform layer of gray phosphating film that is not easy to rust is formed on the surface of the sheet metal, followed by a second washing in the washing tank, and spray cleaning with deionized water, and the cleaned substrate i...

Embodiment 2

[0026](1) Pretreatment: Spray pre-degreasing for 1.5 minutes on the surface of the elevator door and door cover sheet metal, and degrease for 3 minutes. The construction method is spraying, the spraying pressure is 0.15MPa, and the working temperature is 55±5°C , the alkalinity is 0.28pt. Then perform the first water washing in the water washing tank, that is, spray and wash with deionized water for 2 minutes, and wash away the residue after the degreasing treatment on the substrate. Then use a surface conditioner with pH = 8 for surface adjustment, and then use a phosphating solution with a total acidity of 24pt, a free acidity of 1.0pt, and an accelerator concentration of 3pt to phosphate the substrate for 3 minutes. The phosphating process uses spraying In this way, a uniform layer of gray phosphating film that is not easy to rust is formed on the surface of the sheet metal, and then the second washing is carried out in the washing tank, that is, the deionized water spray c...

Embodiment 3

[0031] (1) Pre-treatment: Spray pre-degreasing the surface of the elevator door and door cover sheet metal parts for 1min, degreasing for 5min, the construction method is spraying, the spraying pressure is 0.15MPa, and the working temperature is 55±5°C. Alkalinity at 20pt. Then perform the first water washing in the water washing tank, that is, spray and wash with deionized water for 2 minutes, and wash away the residue after the degreasing treatment on the substrate. Then use a surface conditioner with pH=8 for surface adjustment, and then use a phosphating solution with a total acidity of 20pt, a free acidity of 1.0pt, and an accelerator concentration of 3pt to phosphate the substrate for 5 minutes. The phosphating process uses spraying In this way, a uniform layer of gray phosphating film that is not easy to rust is formed on the surface of the sheet metal, and then the second washing is carried out in the washing tank, that is, the deionized water spray cleaning process is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com