Waste gas purifying and weighing integrated reaction kettle device

A technology for waste gas purification and purification device, which is applied in chemical/physical/physical-chemical stationary reactors, feeding devices, chemical instruments and methods, etc. Affect the health of employees and other problems, achieve the effects of changing the uneven mixing, avoiding environmental pollution and resource waste, and speeding up the response speed of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

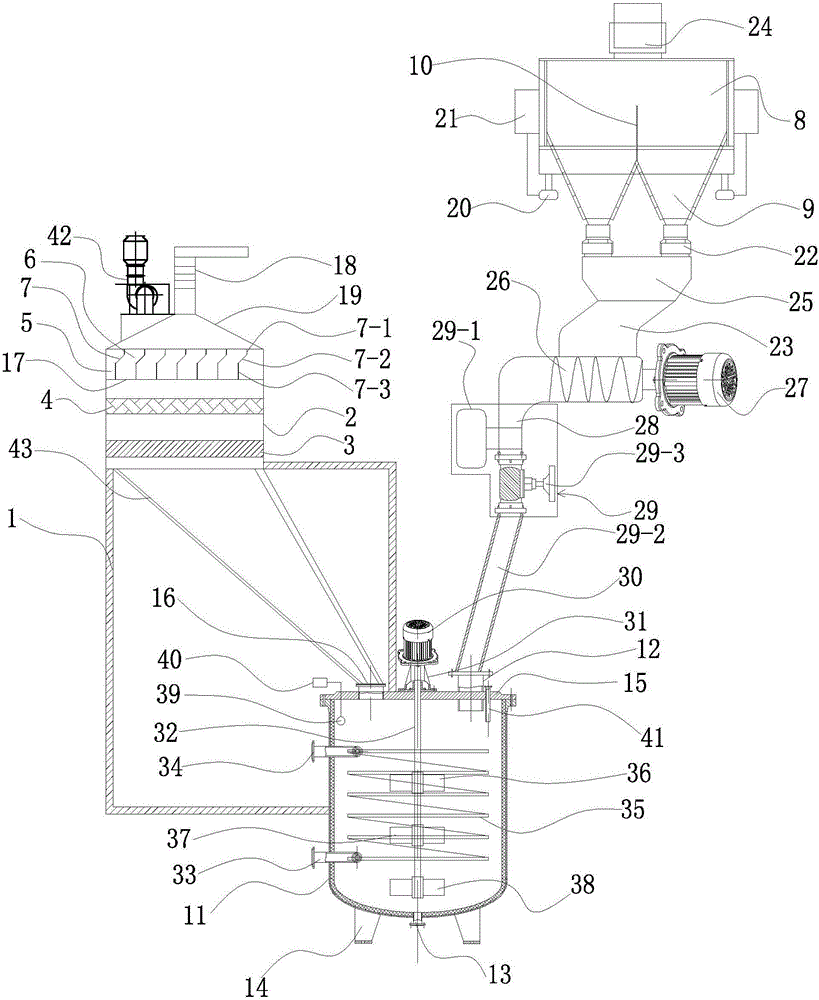

[0028] Embodiment 1: as figure 1 As shown, an integrated reactor device for waste gas purification and weighing, including a kettle body 11, a waste gas treatment and purification device and a weighing device arranged on the top of the kettle body 11; the top of the kettle body 11 is provided with a kettle cover 15 , the kettle cover 15 is provided with a feed port 12, an exhaust hole 16 and a thermometer sleeve 41; the waste gas treatment and purification device is located at the upper end of the kettle body 11 and is fixed by the mounting bracket 1; the bottom of the waste gas treatment and purification device is installed with a horn Type of first connecting pipe 43, the bottom of the first connecting pipe 43 is connected with the exhaust hole 16; by setting the exhaust gas treatment and purification device, using the first connecting pipe 43 to produce a large amount of high concentration in the process of preparing the adhesive resin by reaction The organic waste gas is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com