Manufacture of granule fertilizer roller cover, granulator and fertilizer production system using the same

A production system and granulator technology, which is applied in phosphate fertilizer granulation/granulation, die extrusion granulation, phosphate fertilizer, etc. Granulation rate, improve granulation efficiency, avoid the effect of material breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and examples.

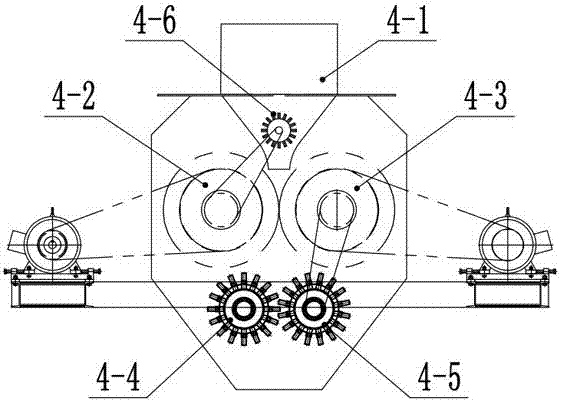

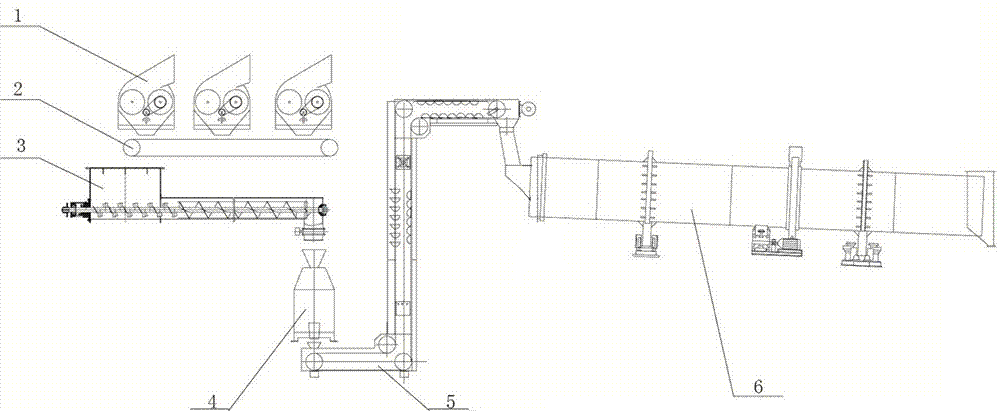

[0047] Such as image 3 , Figure 4 and Figure 5 , the fertilizer production system of the present invention comprises a crusher 1 and a conveyor belt 2 positioned below the discharge port 1-6 of the crusher 1, a screw agitating feeder 3 is arranged below the conveyor belt 2, and the function of the screw agitating feeder 3 is The materials crushed by different crushers 1 are uniformly mixed and sent to the subsequent granulator 4 .

[0048] This embodiment also includes a granulator 4 , a hoist 5 and an abrasive drum 6 . The feeding port of the screw agitating feeder 3 is located directly below the feeding end of the conveyor belt 2, and the discharging end of the screw agitating feeder 3 is located directly above the feeding port of the granulator 4. The feed port 5-5 of the elevator 5 is located directly below the discharge end of the granulator 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com