Granulated bacteria agent and producing method thereof

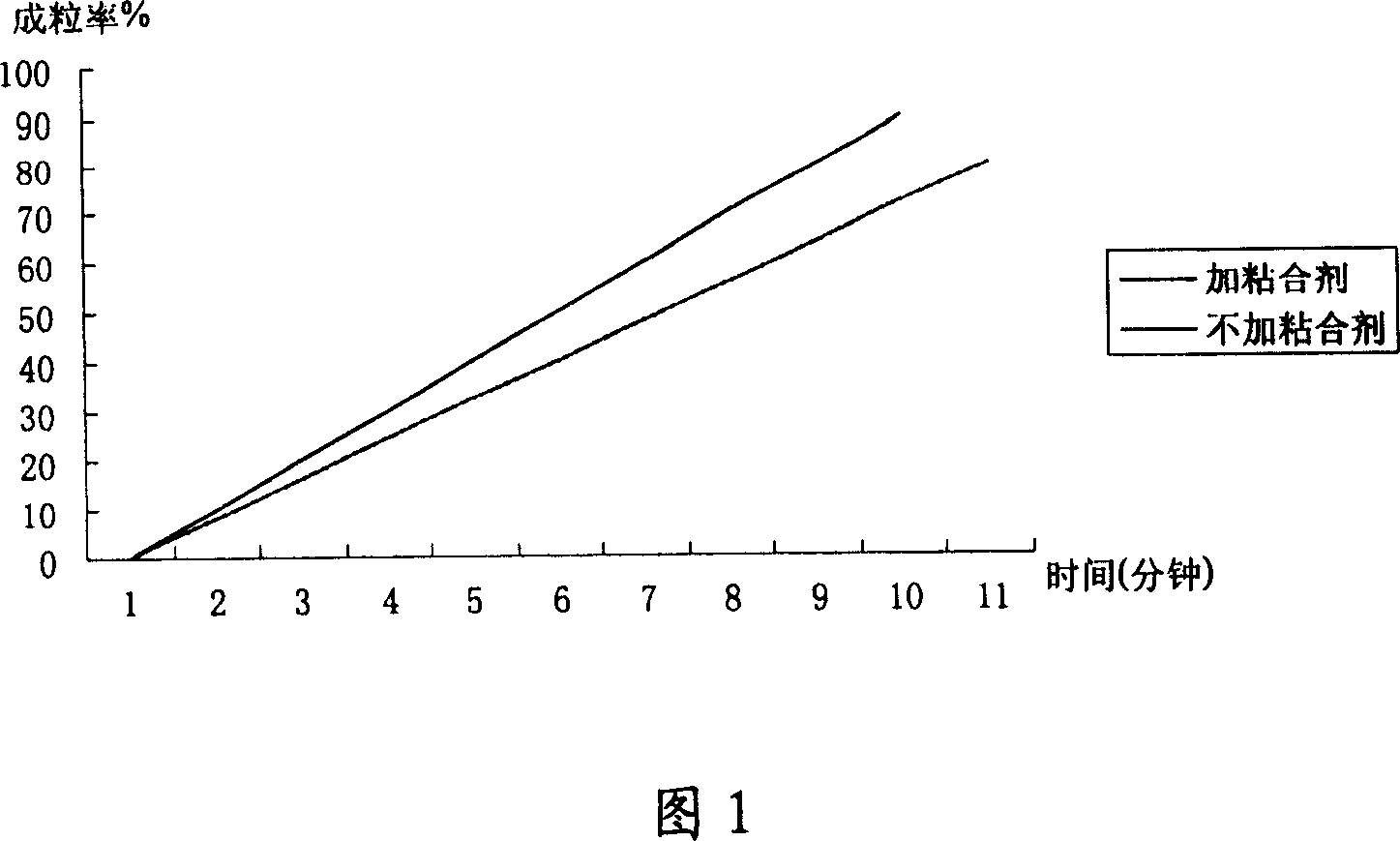

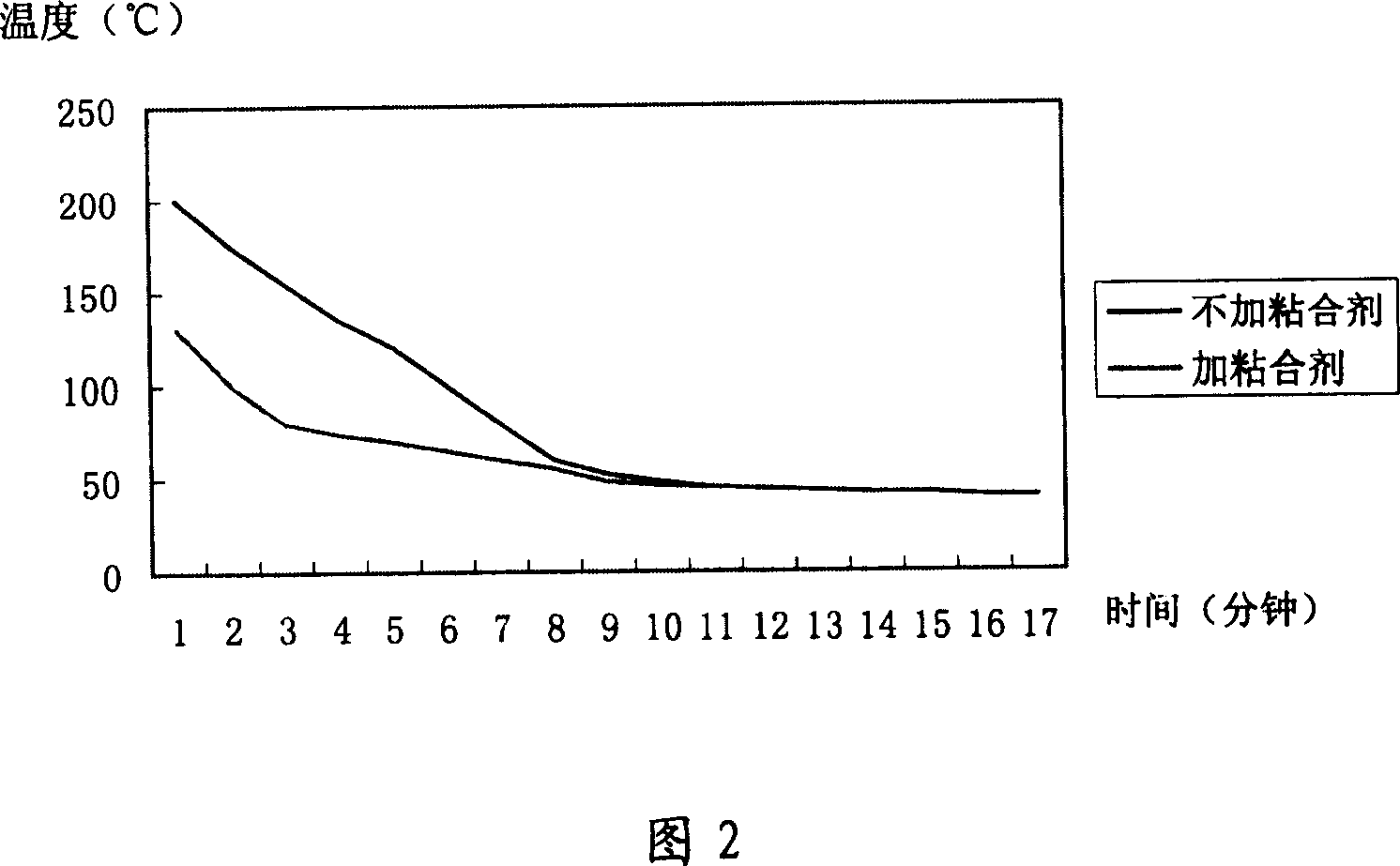

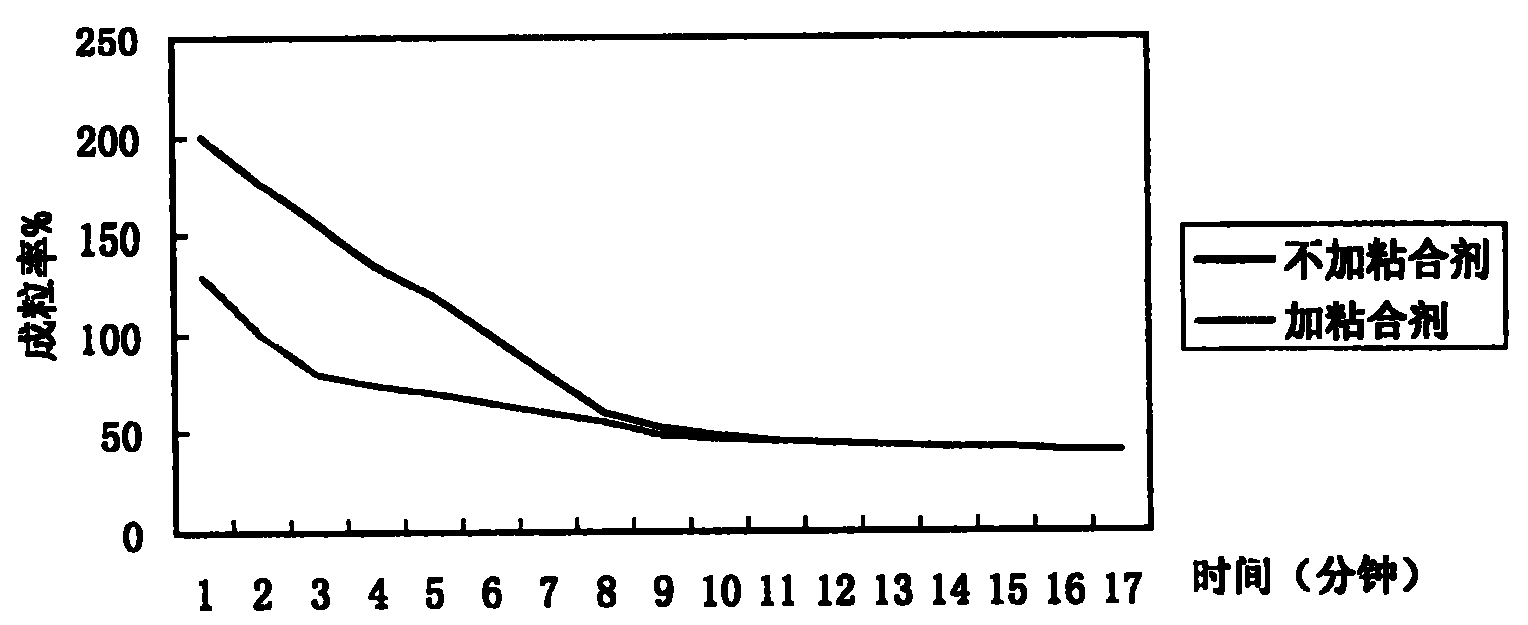

A production method and technology for inoculum, which are applied in the field of granular inoculum and its production, can solve the problems of easily changing the pH value and carbon-nitrogen ratio of the original inoculum, increasing the mortality rate of viable bacteria, and changing the composition of the inoculum medium. , to achieve the effect of easy strain reproduction, shortening granulation time, and benefiting machine insertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Get 850kg of inoculum produced by Beijing Century Arms Biotechnology Co., Ltd., the inoculum of Bacillus cereus is powdery, with a fineness of 100% passing through a 60-mesh sieve, and moisture≤25%. Take 150kg of auxiliary material talcum powder, the auxiliary material is powdery, and the fineness is 100% and passes through a 120 mesh sieve, firstly mixed manually, and put into a mechanical mixer to mix until uniform, then transported to the granulator, and then added separately The aqueous solution of binder plastic methyl cellulose is carried out spray granulation (the solution of binder is 8% aqueous solution), and the consumption of aqueous solution is 228kg. The granulated material is sent into the drum dryer for co-current drying with hot drying gas and the material, and the drying time of the material is fixed at 18 minutes. The water content of the product is controlled within the range of 12-16%, and the dried material is sent to the cooler to cool to room temp...

Embodiment 2

[0038] With embodiment 1, wherein bacterium agent 850kg, auxiliary material is bentonite, and consumption is 175kg; The concentration of binder aqueous solution is 5%, and the consumption of aqueous solution is 230kg.

Embodiment 3

[0040] With embodiment 1, wherein bacterial agent is 900kg, and auxiliary material is silicon bath soil, and consumption is 86kg, and binding agent is starch aqueous solution, and concentration is 2%, and consumption is 184kg.

[0041] The composition of granule bacterial agent is as table 2 (dry basis) in each example

[0042] Table 2

[0043]

[0044] The bacteria agent provided by the invention has high strength, convenient and flexible use. The production method is more economical and fast, shortens the granulation time, saves granulation water, and reduces the drying load.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com