Antibacterial reverse osmosis composite membrane and preparation method and application thereof

A reverse osmosis composite membrane and technology of reverse osmosis membrane are applied in the field of antibacterial reverse osmosis composite membrane, its preparation and application, which can solve the problems affecting the application and promotion of reverse osmosis composite membrane, and achieve the improvement of anti-pollution performance, prolonging service life, The effect of increasing the salt interception rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1 prepares antibacterial reverse osmosis composite membrane according to the following steps:

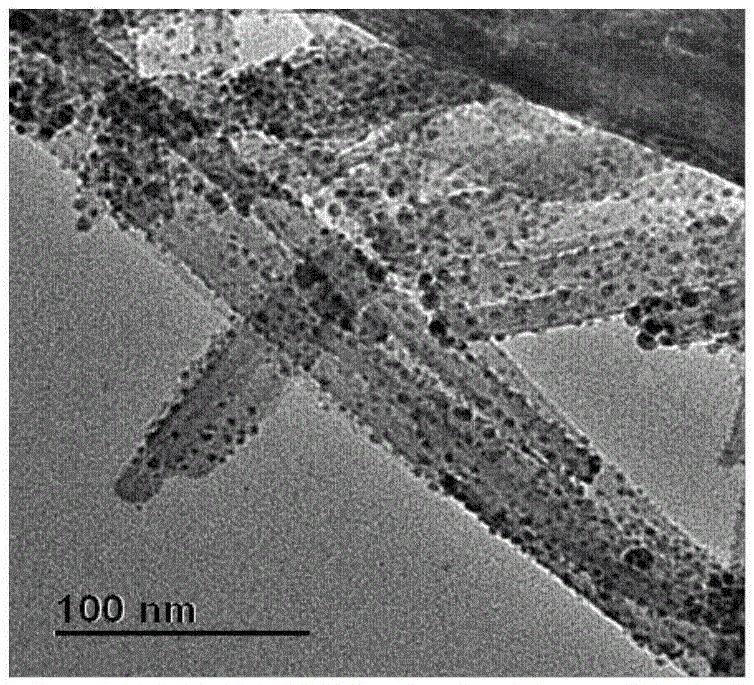

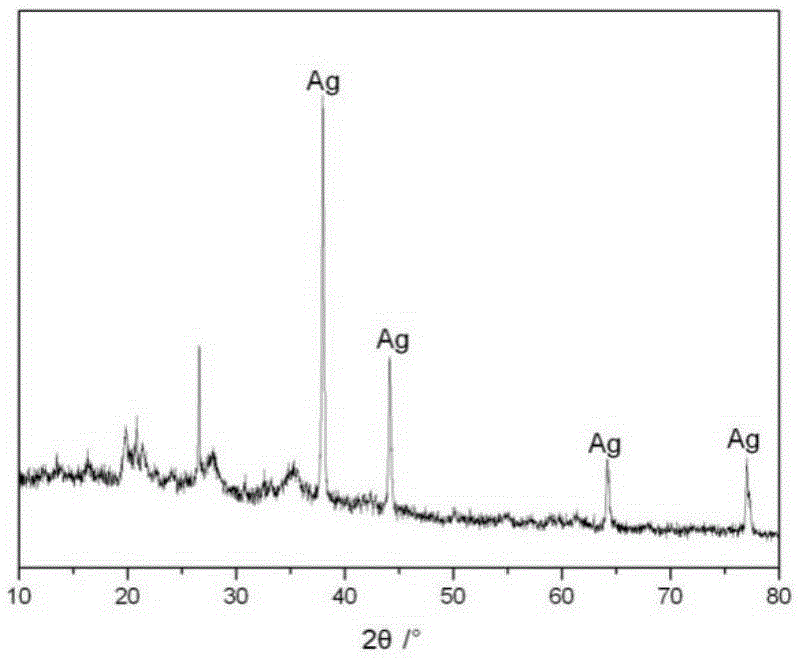

[0061] (1) Preparation of attapulgite-nano-silver composite inorganic antibacterial agent: take attapulgite (AT) through thermal activation and dispersion treatment, be mixed with attapulgite mass concentration and be 1% aqueous suspension, then silver nitrate Solution (AgNO 3 / AT=17 / 100) was added to the attapulgite suspension, stirred magnetically for 1 h at 50°C, and then the attapulgite suspension was spray-dried at 200°C, and the composite powder obtained by spray drying was collected. Finally, the obtained composite powder was calcined in a muffle furnace at 500° C. for 30 minutes to obtain the attapulgite-nanometer silver composite inorganic antibacterial agent. The above-mentioned composite powder prepared by spray drying and the composite powder obtained after calcination were characterized by XRD and TEM respectively, and the results showed that the silv...

Embodiment 2

[0064] Embodiment 2 prepares antibacterial reverse osmosis composite membrane according to the following steps:

[0065] (1) Preparation of attapulgite-nano-silver composite inorganic antibacterial agent: except that the temperature of magnetic stirring after mixing the silver nitrate solution and attapulgite suspension was adjusted to 70°C, the results of other process steps and XRD and TEM characterization were consistent. Same as Example 1.

[0066] (2) Preparation of reverse osmosis composite membrane: the method is the same as in Comparative Example 1.

[0067] (3) Preparation of antibacterial reverse osmosis composite membrane: except that the mass concentration of PVA (alcoholysis degree is 88%) is adjusted to 1% in the coating solution, the mass concentration of glutaraldehyde is adjusted to 0.1%, and the mass concentration of hydrochloric acid is adjusted to Except for 0.1%, other process steps and test conditions are all the same as in Example 1, and the test result...

Embodiment 3

[0068] Embodiment 3 prepares antibacterial reverse osmosis composite membrane according to the following steps:

[0069] (1) Preparation of attapulgite-nano-silver composite inorganic antibacterial agent: Except for adjusting the temperature of magnetic stirring to 90°C after mixing silver nitrate solution and attapulgite suspension, other process steps and XRD and TEM characterization results were consistent. Same as Example 1.

[0070] (2) Preparation of reverse osmosis composite membrane: the method is the same as in Comparative Example 1.

[0071] (3) Preparation of antibacterial reverse osmosis composite membrane: except that the mass concentration of PVA (degree of alcoholysis is 95%) is adjusted to 1.5% in the coating solution, the mass concentration of glutaraldehyde is adjusted to 0.15%, and the mass concentration of hydrochloric acid is adjusted to Except for 0.15%, other process steps and test conditions are all the same as in Example 1, and the test results of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com