Composite biological fresh-keeping agent used for squid, and fresh-keeping method thereof

The technology of a biological preservative and fresh-keeping method is applied in the field of fresh-keeping of aquatic products, which can solve the problems of low safety of squid meat chemical preservatives, achieve good antibacterial and anti-oxidative effects, less process steps, and eliminate formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

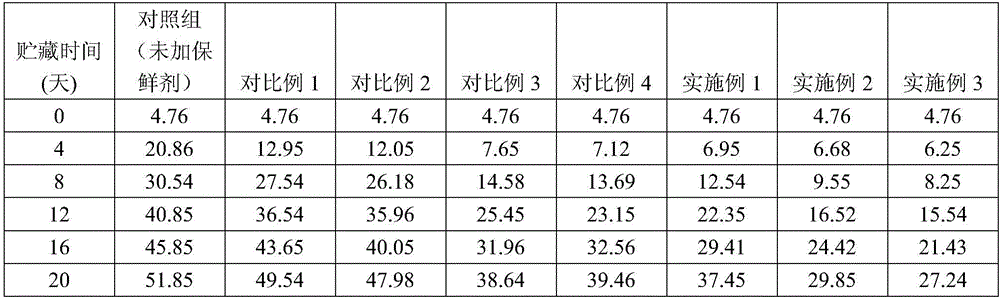

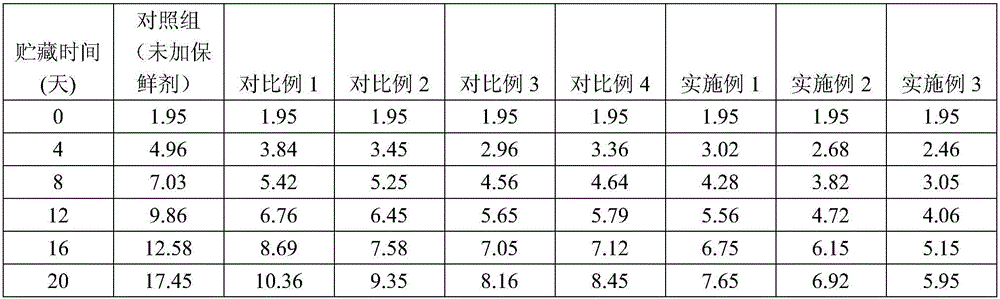

Examples

Embodiment 1

[0034] (1) Preparation of enzymatic hydrolyzate of flounder leftovers

[0035] High-pressure cooking (121°C, 15min) of flounder leftovers (fish head, bone, skin), dried (80°C, 2h), and mixed with water (mass ratio of leftovers to water: 1:5 (g / mL)) , homogenate, adjust temperature to 40°C, adjust pH to 7.0 with sodium hydroxide, add trypsin accounting for 0.5% of the total mass of flounder leftovers, hydrolysis time is 4h, inactivate enzyme, centrifuge (5000×g, 15min), take The supernatant was concentrated and freeze-dried to obtain the enzymatic hydrolyzate of plaice leftover protein;

[0036] (2) Preparation of laminarin

[0037] Clean the kelp with deionized water, dry it at 105°C for 30 minutes, grind the dried kelp into kelp powder, and extract kelp polysaccharide with the help of ultrasonic waves. The time is 50min, the ultrasonic power is 600W, the extraction temperature is 60°C, the ratio of solid to liquid is 1:30 (g / mL), filtered, and evaporated with a rotary evapo...

Embodiment 2

[0046] (1) Preparation of enzymatic hydrolyzate of flounder leftovers

[0047]High-pressure cooking (121°C, 15min) of flounder leftovers (fish head, bone, skin), dried (80°C, 2h), and mixed with water (mass ratio of leftovers to water: 1:5 (g / mL)) , homogenate, adjust the temperature to 40°C, adjust the pH to 7.5 with sodium hydroxide, add trypsin accounting for 0.7% of the total mass of plaice leftovers, hydrolyze for 4 hours, inactivate the enzyme, centrifuge (5000 × g, 15min), and take The supernatant was concentrated and freeze-dried to obtain the enzymatic hydrolyzate of plaice leftover protein;

[0048] (2) Preparation of laminarin

[0049] Clean the kelp with deionized water, dry it at 105°C for 30 minutes, grind the dried kelp into kelp powder, and extract kelp polysaccharide with the help of ultrasonic waves. The time is 50min, the ultrasonic power is 600W, the extraction temperature is 60°C, the ratio of solid to liquid is 1:30 (g / mL), filtered, evaporated by rotar...

Embodiment 3

[0059] (1) Preparation of enzymatic hydrolyzate of flounder leftovers

[0060] High-pressure cooking (121°C, 15min) of flounder leftovers (fish head, bone, skin), dried (80°C, 2h), and mixed with water (mass ratio of leftovers to water: 1:5 (g / mL)) , homogenate, adjust the temperature to 40°C, adjust the pH to 8.0 with sodium hydroxide, add trypsin accounting for 1.0% of the total mass of plaice leftovers, hydrolyze for 4 hours, inactivate the enzyme, centrifuge (5000 × g, 15min), and take The supernatant was concentrated and freeze-dried to obtain the enzymatic hydrolyzate of plaice leftover protein;

[0061] (2) Preparation of laminarin

[0062] Clean the kelp with deionized water, dry it at 105°C for 30 minutes, grind the dried kelp into kelp powder, and extract kelp polysaccharide with the help of ultrasonic waves. The time is 50min, the ultrasonic power is 600W, the extraction temperature is 60°C, the ratio of solid to liquid is 1:30 (g / mL), filter, and use rotary evapo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com