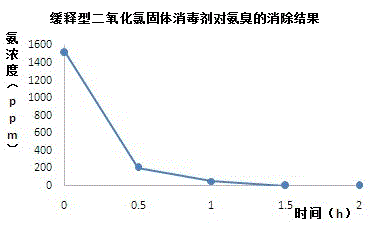

Slow release type chlorine dioxide solid disinfectant and preparation method thereof

A chlorine dioxide precursor, chlorine dioxide technology, applied in the direction of disinfectants, botany equipment and methods, disinfection, etc., can solve the problems of inconvenient use at home, instability of gaseous chlorine dioxide, difficulty in achieving slow release, etc. Achieve the effect of long shelf life, good application prospect and easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Example 1 A slow-release chlorine dioxide solid toilet sterilization and deodorant (A:B=50g:30g)

[0065] Formula: Component A: 20% sodium chlorate, 15% sodium sulfite, 42% silica gel powder, 8% diatomaceous earth, 15% polyvinyl alcohol; component B: 5% sodium bisulfate, 5% sodium dihydrogen phosphate, Purified water 90%.

[0066] Preparation method: crush sodium chlorate and sodium sulfite through a 60-mesh sieve, and set aside. Dry sodium chlorate at 50-60°C for 8 hours; dry sodium sulfite and silica gel powder at 50-60°C for 4 hours. Dry the polyvinyl alcohol at a temperature of 60~70°C for 4 hours. According to the formula ratio, sodium chlorate, sodium sulfite, and silica gel powder are evenly mixed, and loaded into the lower layer of the double-layer slow-release device; diatomaceous earth and polyvinyl alcohol are evenly mixed, and then loaded into the upper layer of the double-layer slow-release device. According to the formula ratio, sodium bisulfate and sod...

Embodiment 2

[0069] Example 2 A slow-release chlorine dioxide solid indoor fungicide (A:B=100g:50g)

[0070] Formula: Component A: Potassium Chlorate 20%, Potassium Sulfite 20%, Polyacrylic Resin 38%, Sodium Silicate 7%, Polyvinyl Alcohol 15%; Component B: Potassium Hydrogen Sulfate 5%, Potassium Dihydrogen Phosphate 5% %, purified water 90%.

[0071] Preparation method: crush potassium chlorate and potassium sulfite through a 60-mesh sieve, and set aside. Potassium chlorate is dried at a temperature of 50-60°C for 8 hours; potassium sulfite and polyacrylic acid resin are dried at a temperature of 50-60°C for 4 hours. Dry the polyvinyl alcohol at a temperature of 60~70°C for 4 hours. According to the formula ratio, potassium chlorate, potassium sulfite and polyacrylic acid resin are evenly mixed, and loaded into the lower layer of the double-layer slow-release device; sodium silicate and polyvinyl alcohol are evenly mixed, and then loaded into the upper layer of the double-layer slow-rel...

Embodiment 3

[0072] Example 3 A slow-release chlorine dioxide solid refrigerator deodorant (A:B=20g:10g)

[0073] Formula: Component A: Sodium Chlorate 15%, Sodium Sulfite 15%, Hydroxymethyl Cellulose 54%, Diatomaceous Earth 6%, Polyvinyl Alcohol 10%; Component B: Sodium Bisulfate 5%, Sodium Dihydrogen Phosphate 5%, purified water 90%.

[0074] Preparation method: crush sodium chlorate and sodium sulfite through a 60-mesh sieve, and set aside. Dry sodium chlorate at 50-60°C for 8 hours; dry sodium sulfite and hydroxymethyl cellulose at 50-60°C for 4 hours. Dry the polyvinyl alcohol at a temperature of 60~70°C for 4 hours. According to the formula ratio, sodium chlorate, sodium sulfite and hydroxymethyl cellulose are uniformly mixed, and loaded into the lower layer of the double-layer slow-release device; diatomaceous earth and polyvinyl alcohol are evenly mixed, and then loaded into the upper layer of the double-layer slow-release device. According to the formula ratio, sodium bisulfate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com