Catalyst component and its preparation method and application and catalyst system for olefin polymerization and its application and olefin polymerization method

An olefin polymerization and catalyst technology, applied in the application field of the catalyst system, can solve the problems of low polymerization activity, poor hydrogen adjustment sensitivity, and the catalyst needs to be further improved, and achieves simple equipment, convenient and easy conversion to production, and improved hydrogen adjustment sensitivity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

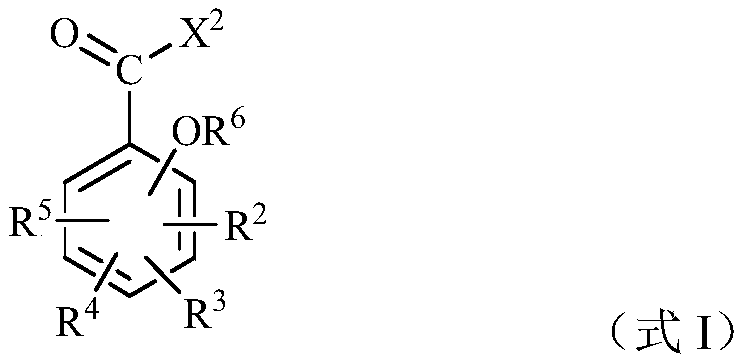

[0063] As mentioned above, the present invention provides a method for preparing a catalyst component for olefin polymerization, the method comprising: carrying out a contact reaction of a magnesium halide adduct, a titanium compound and an aromatic carboxylate compound, the halogenated The preparation step of magnesium adduct comprises:

[0064] (1) the aqueous MgX 1 Y and R 1 OH and an alkoxybenzoyl compound are mixed, and the resulting mixture is heated to obtain a liquid magnesium halide adduct; or

[0065] Anhydrous MgX 1 Y and R 1 OH, an alkoxybenzoyl compound and water are mixed, and the obtained mixture is heated to obtain a liquid magnesium halide adduct;

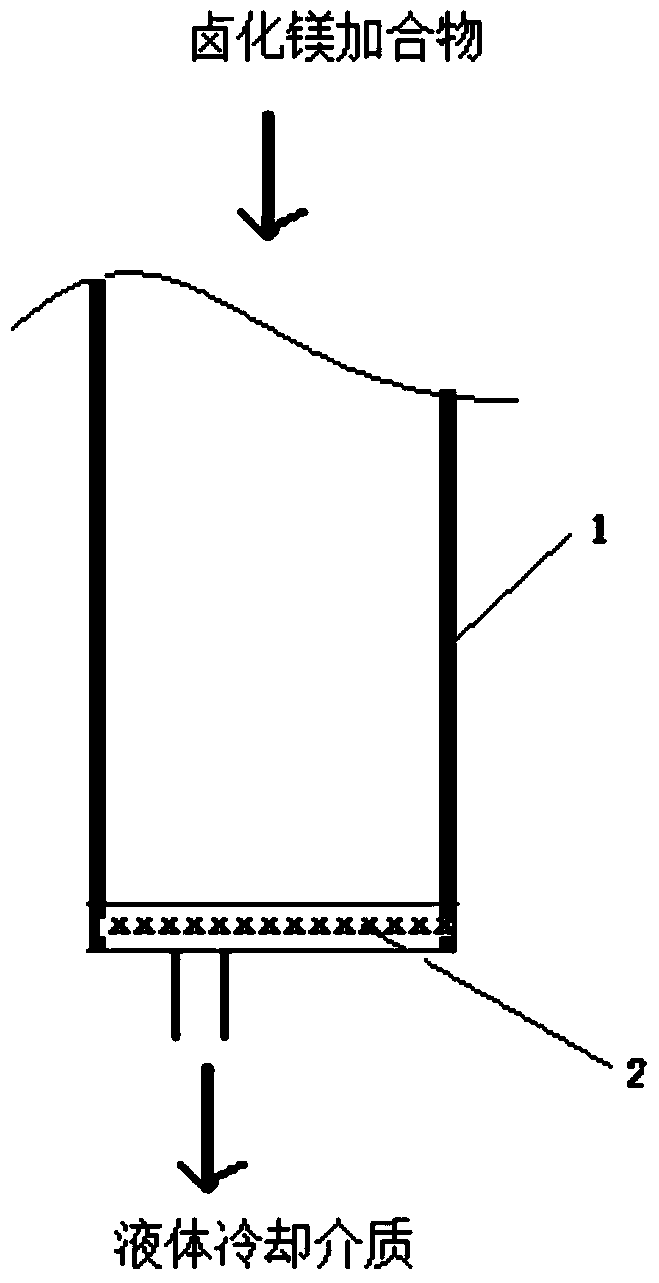

[0066] (2) In the presence of an inert liquid medium, pass the liquid magnesium halide adduct through the structural unit with holes under pressure to the liquid cooling medium for rapid cooling and drying to obtain spherical magnesium halide adduct particles.

[0067] According to the method of the present in...

Embodiment approach

[0092] According to a preferred embodiment of the present invention, the structural unit with holes is a mesh layer.

[0093] According to a preferred embodiment of the present invention, the mesh layer is a metal mesh layer.

[0094] According to the method of the present invention, the adduct solid particles with equivalent particle morphology can be obtained by adopting the metal mesh with multi-layer large-aperture structure and the metal mesh with relatively small number of layers with small-aperture structure. When preparing a small particle size (such as less than 30 μm) adduct carrier, it is preferable to use a metal mesh structure with 1-20 layers of small pore structure (such as a pore size of 30-50 μm). It is preferred to use a metal mesh structure with 1-20 layers of relatively large aperture (eg, 65-200 μm aperture) structure.

[0095] According to a preferred embodiment of the present invention, the mesh layer includes 1-20 layers, preferably 2-8 layers, more pr...

preparation Embodiment 1

[0147] In a 1000mL reaction kettle, add 150mL of white oil (commercially purchased from Guangzhou Mingen Petrochemical Co., Ltd., with a water content of less than 50ppm by weight), 300mL of methyl silicone oil (commercially purchased from Dow Corning, with a viscosity of 300 centipoise / 20°C, by weight, the water content is less than 50ppm), 30g magnesium chloride containing 0.44wt% moisture (commercially purchased from Fushun Xinyi Titanium Factory), 50mL absolute ethanol (commercially purchased from Beijing Chemical Plant, by weight , the water content is less than 100 ppm) and 1 mL of 2-methoxybenzoyl chloride (commercially purchased from TOKYO KASEI KOGYO CO.LTD), and the temperature was raised to 125° C. under stirring. After 3 hours of constant temperature reaction, the mixture was pressed into 2L of hexane pre-cooled to -30°C (with By weight, the water content is lower than 5ppm), and quenched and formed. The liquid was removed by filtration, and the obtained solid wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com