Annular extrusion air-cooling apparatus and pipe extrusion molding apparatus

An air-cooling device, a ring-shaped technology, applied in the direction of tubular objects, other household appliances, household appliances, etc., can solve the problems of long process response time, poor cooling effect, slow cooling speed, etc., to achieve better effect, stable gas output, Easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

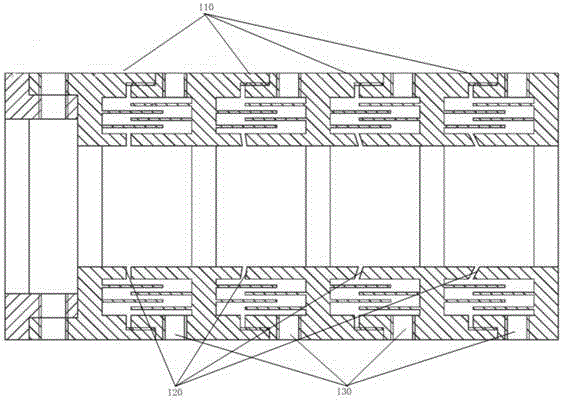

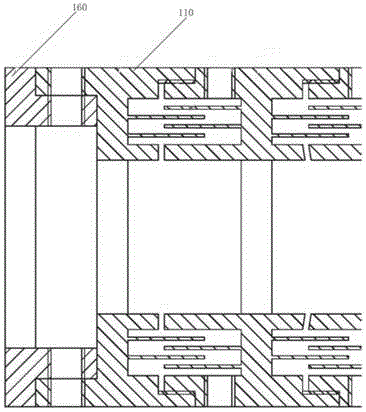

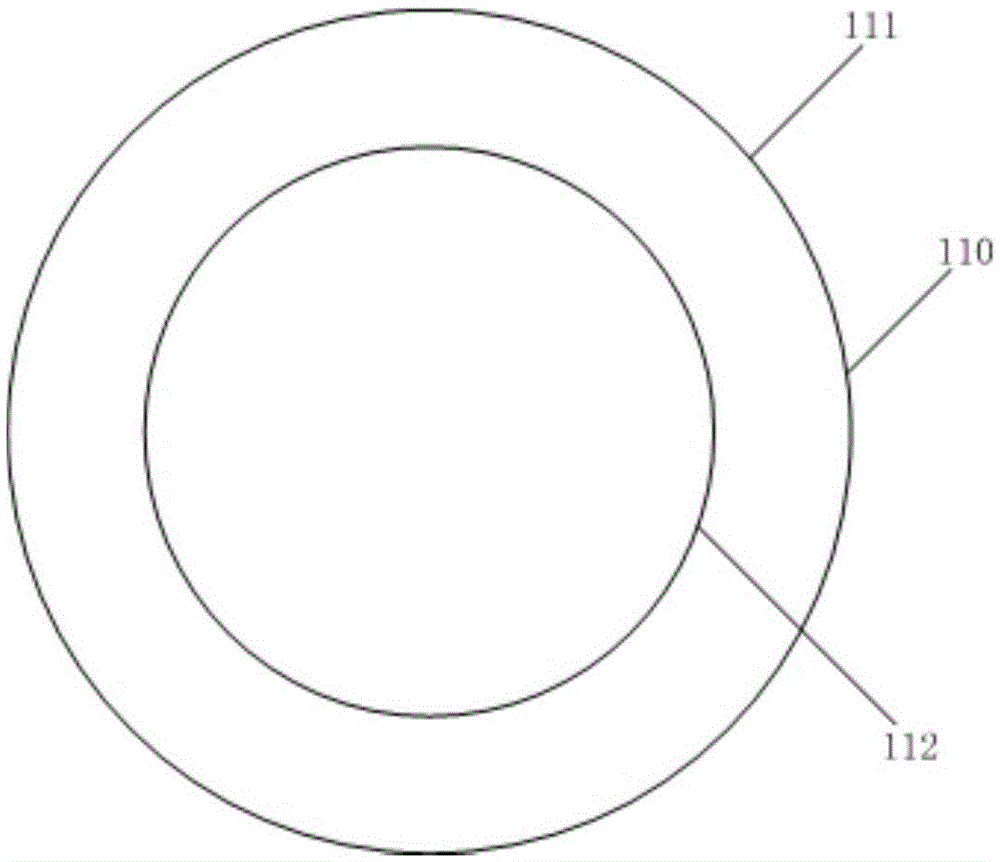

[0029] In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the present invention will be specifically described below in conjunction with the accompanying drawings and embodiments. The drawings in the following description are only some embodiments of the invention. For those skilled in the art, other drawings can also be obtained based on these drawings without creative effort.

[0030] Considering that in the prior art, during the production of pipes, due to the slow cooling rate of the extruded pipes, the process response time is long, the cooling effect is not ideal, and the extruded pipes cannot be pre-cooled quickly after they are released from the mold, resulting in the occurrence of pipe blanks. To solve problems such as subsidence, the present invention designs a new type of cold air device, through the air cooling device installed directly at the extrusion port, and through the air outlet installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com