Methanol-to-aromatic hydrocarbon catalyst and uses tehreof

A technology for catalysts and aromatics, which is applied in molecular sieve catalysts, physical/chemical process catalysts, and hydrocarbon production from oxygen-containing organic compounds. The effect of mild conditions and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

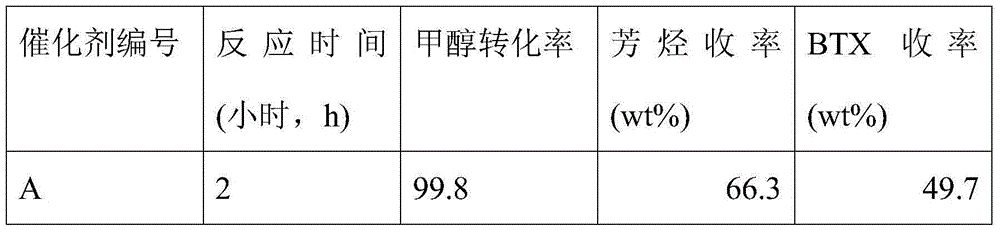

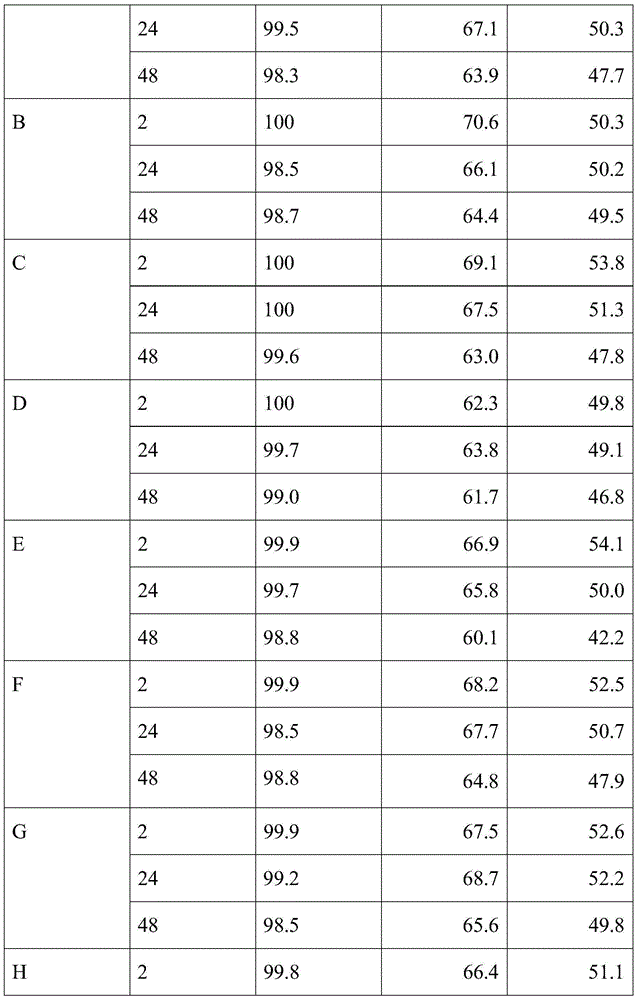

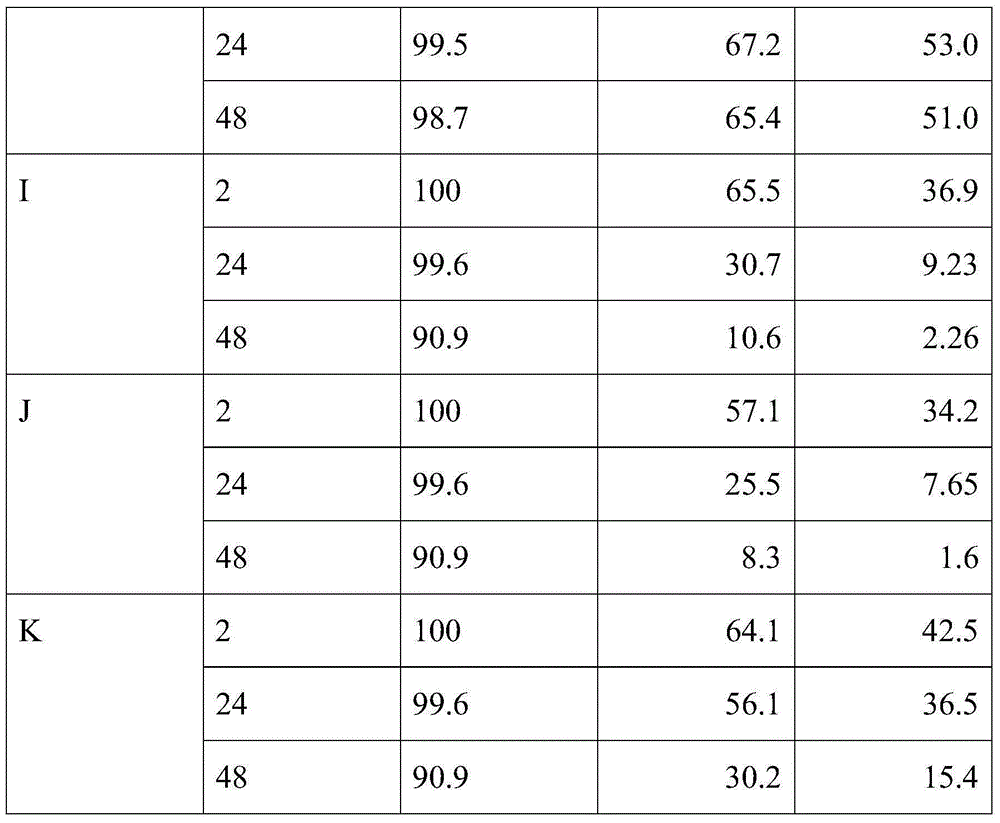

Examples

Embodiment 1

[0024] Add 19 g of tetrapropylammonium bromide, 3.3 g of sodium hydroxide, and 9.8 g of aluminum isopropoxide into 180 g of deionized water, and vigorously stir and hydrolyze at room temperature for 6 hours to obtain solution A. Add 127 g of ethyl orthosilicate, 1.2 g of sodium hydroxide, and 5.3 g of polyoxyethylene lauryl ether into 120 g of water, and stir vigorously for 5 hours to obtain solution B. After mixing A and B, stir at room temperature for 6 hours, transfer the obtained mixed solution into a stainless steel crystallization kettle, and conduct hydrothermal treatment at 180° C. for 50 hours. After the crystallization is complete, the obtained white powder is filtered and washed repeatedly with deionized water until neutral. Dry the white powder at 110°C, calcinate at 550°C for 8 hours, exchange the molecular sieve with 0.5 mol / L ammonium nitrate three times, dry and calcinate according to the previous steps, and obtain a hydrogen-type medium with a silicon-aluminum...

Embodiment 2

[0028] Using the carrier I of Example 1, take 15 grams of carrier I, soak it in 11 milliliters of zinc nitrate solution containing 1.1 grams of zinc oxide, let it stand at room temperature for 24 hours, dry it, and bake it at 560° C. for 4 hours to prepare catalyst B. The reaction conditions are the same as in Example 1.

Embodiment 3

[0030] Add 7.8 g of n-butylamine, 2.3 g of sodium hydroxide, and 6.0 g of sodium metaaluminate into 150 g of deionized water, and vigorously stir and hydrolyze at room temperature for 5 hours to obtain solution A. Add 127 grams of ethyl orthosilicate, 1.5 grams of sodium hydroxide, and 6.2 grams of polyvinyl alcohol into 120 grams of water, and stir vigorously for 7 hours to obtain solution B. A and B were mixed and then stirred at room temperature for 4 hours to obtain a mixed solution. Other conditions are identical with embodiment 1. According to the specific surface area test, the total specific surface area of the mesoporous ZSM-5 molecular sieve is 415m 2 / g, the mesopore specific surface area is 125m 2 / g, the average pore diameter is 7.7nm.

[0031]Take 20 grams of molecular sieves, 1.2 grams of turnip powder, and 24 grams of silica sol with a mass concentration of 40% and fully knead them, extrude them, dry and roast them to make catalyst carrier II. Take 15 gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com