Surface mounting method for printed circuit board

A printed circuit board, surface mount technology, applied in the direction of printed circuit, printed circuit manufacturing, printed circuit assembly of electrical components, etc., can solve the problem of SMD large device dropouts and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In this embodiment, a surface mounting method for a printed circuit board, wherein the printed circuit board is provided with a tantalum capacitor (type D), comprises the following steps:

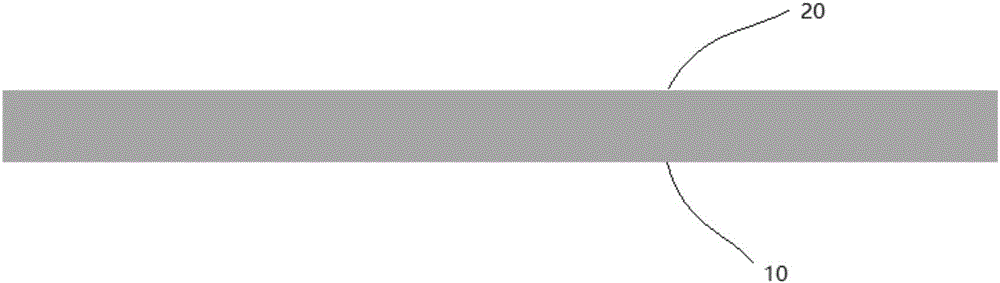

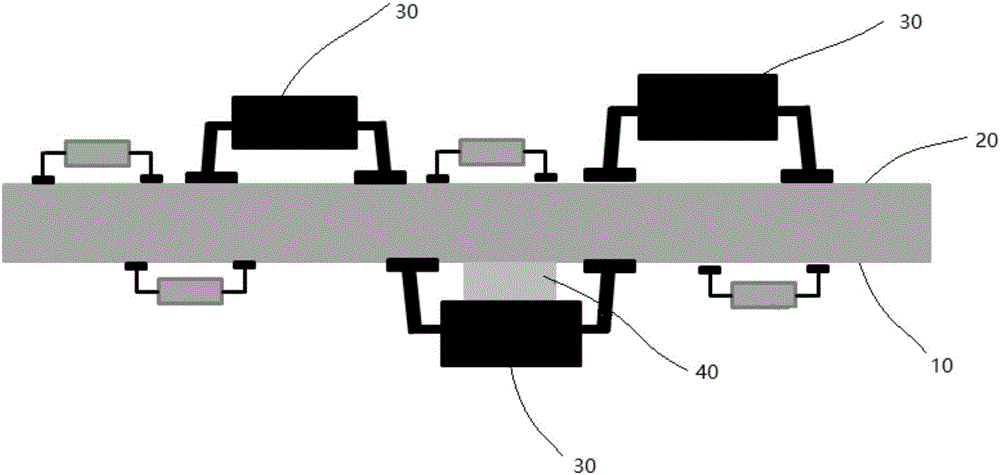

[0044] (1) Obtain an empty board: such as figure 1 As shown, the empty board includes a first surface 10 and a second surface 20, and the first surface 10 is provided with a large device mounting area for mounting tantalum capacitors, and the large device mounting area includes solder feet corresponding to tantalum capacitors The pad area and the blank area corresponding to the body of the tantalum capacitor;

[0045] (2) PCB layout design: place the tantalum capacitor design on the second surface 20 first, and then place the tantalum capacitor on the first surface 10 when the layout cannot be completed on the second surface 20;

[0046] (3) Printing on the first side: print solder paste on the pad area on the first side 10 according to the conventional procedure;

[0047] (4) Glu...

Embodiment 2

[0052] In this embodiment, a surface mounting method for a printed circuit board, wherein the printed circuit board is provided with a tantalum capacitor (type D), comprises the following steps:

[0053] (1) Obtain an empty board: the empty board includes a first side and a second side. The first side is provided with a large component mounting area for mounting tantalum capacitors. The corresponding pad area, and the blank area corresponding to the body of the tantalum capacitor;

[0054] (2) PCB layout design: place the tantalum capacitor design on the second side first, and then place the tantalum capacitor on the first side when the layout cannot be completed on the second side;

[0055] (3) Printing on the first side: Print solder paste on the pad area on the first side according to the conventional process;

[0056] (4) Glue dispensing and patching on the first side: Use a glue dispensing machine to dispens glue in the middle of the blank area on the first side to form ...

Embodiment 3

[0061] In this embodiment, a surface mounting method for a printed circuit board, wherein the printed circuit board is provided with a tantalum capacitor (type D), comprises the following steps:

[0062] (1) Obtain an empty board: the empty board includes a first side and a second side. The first side is provided with a large component mounting area for mounting tantalum capacitors. The corresponding pad area, and the blank area corresponding to the body of the tantalum capacitor;

[0063] (2) PCB layout design: place the tantalum capacitor design on the second side first, and then place the tantalum capacitor on the first side when the layout cannot be completed on the second side;

[0064] (3) Printing on the first side: Print solder paste on the pad area on the first side according to the conventional process;

[0065] (4) Glue dispensing and patching on the first side: Use a glue dispensing machine to dispens glue in the middle of the blank area on the first side to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com