Sugar cane juice Maillard reaction product, preparation method thereof and application thereof to cigarettes

A technology of Maillard reaction and sugarcane juice, which is applied in Maillard reaction products and application fields, can solve problems that have not been reported, and achieve the effects of low cost, simple operation, and improved sensory comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

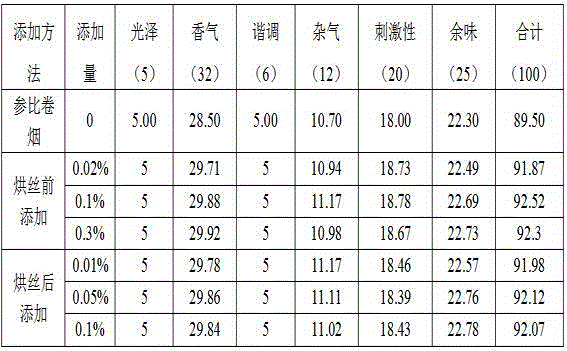

Examples

Embodiment 1

[0020] (1) Cleaning, juicing, and filtering: Select sugarcane with thick stems and no damage, moths or diseases, cut them into 10cm long sections, add water to clean them, put the sugarcane in a juicer for 5 minutes, and extract all the juice Squeeze out; then use a filter with a filter mesh diameter of 0.5mm for coarse filtration to separate the slurry into juice and coarse residue; then put the coarsely filtered juice into a centrifugal filter with a filter mesh diameter of 0.16mm Finely filter the sugarcane juice in the machine;

[0021] (2) Enzymolysis: add invertase with sugarcane juice quality of 2‰ to sugarcane juice, bathe in water at 50°C for 1.5h, then immediately transfer to a water bath at 90°C and heat for 30min to inactivate the enzyme to obtain an enzymolysis solution;

[0022] (3) Concentration: Concentrate the enzymatic hydrolyzate under reduced pressure at 45°C and 65KPa until there is no water to obtain enzymatic hydrolyzate of sugarcane juice;

[0023] (4)...

Embodiment 2

[0028] (1) Cleaning, juicing, and filtering: Select sugarcane with thick stems and no damage, moths or diseases, cut them into 15cm long sections, add clean water for cleaning, put the sugarcane into a juicer and squeeze continuously for 6 minutes, and the juice will be completely Squeeze out; then use a filter with a filter mesh diameter of 0.5mm for coarse filtration to separate the slurry into juice and coarse residue; then place the coarsely filtered juice into a centrifugal filter with a filter mesh diameter of 0.16mm Carry out fine filtration to obtain sugarcane juice;

[0029] (2) Enzymolysis: add invertase with sugarcane juice quality of 5‰ to sugarcane juice, bathe in water at 55°C for 1 hour, then immediately transfer to a water bath at 95°C and heat for 40 minutes to inactivate the enzyme to obtain an enzymolysis solution;

[0030] (3) Concentration: Concentrate the enzymatic hydrolyzate under reduced pressure at 50°C and 60KPa until there is no water to obtain the ...

Embodiment 3

[0036] (1) Cleaning, juicing, and filtering: Select sugarcane with a thick stem and no damage, insects or diseases, cut it into 20cm long sections, add water to clean it, put the sugarcane into a juicer and squeeze it continuously for 7 minutes, and the juice will be completely Squeeze out; then use a filter with a filter mesh diameter of 0.5mm for coarse filtration to separate the slurry into juice and coarse residue; then place the coarsely filtered juice into a centrifugal filter with a filter mesh diameter of 0.16mm Carry out fine filtration to obtain sugarcane juice;

[0037] (2) Enzymolysis: Add invertase with sugarcane juice quality of 3‰ to sugarcane juice, bathe in water at 45°C for 2 hours, then immediately transfer to a water bath at 85°C and heat for 50 minutes to inactivate the enzyme to obtain an enzymolysis solution;

[0038] (3) Concentration: Concentrate the enzymatic hydrolyzate under reduced pressure at 45°C and 70KPa until there is no water to obtain enzyma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com