Assembly method of cast aluminum rotor assembly with built-in magnetic steel

A technology of casting aluminum rotors and assembly methods, which is applied in the direction of electric components, manufacturing stator/rotor bodies, electromechanical devices, etc., can solve the problems of no assembly method and difficulty, and achieve the effect of ensuring the use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

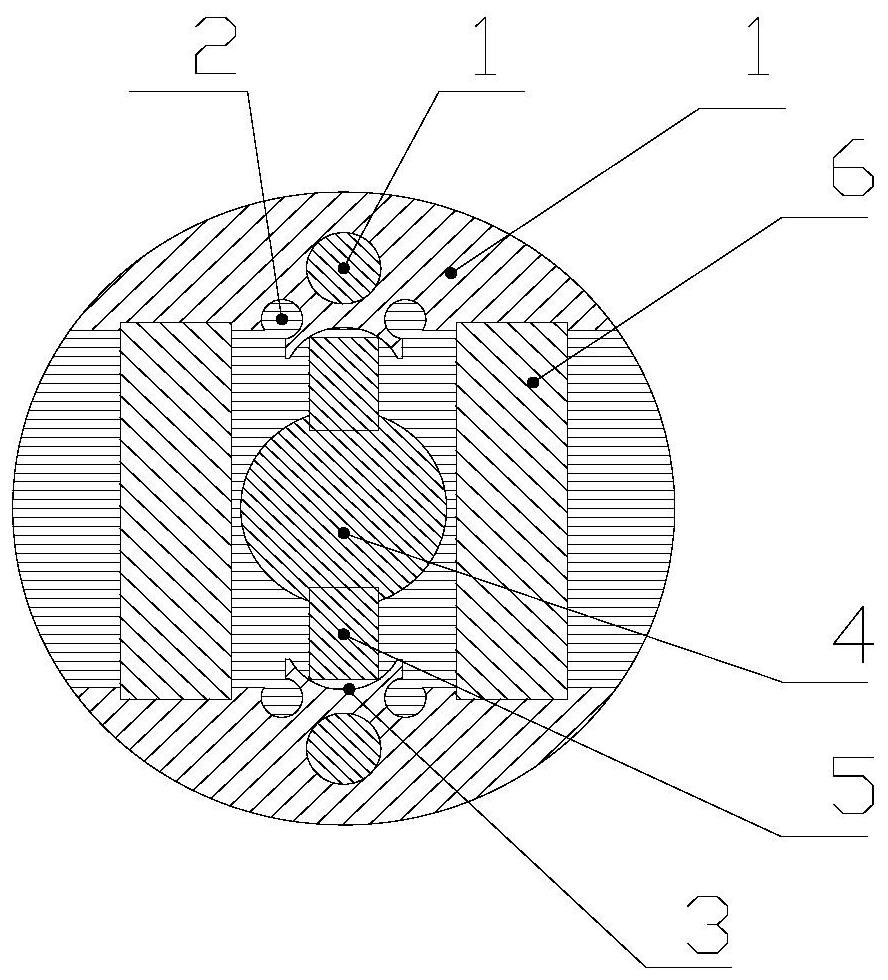

[0015] As shown in the figure, the assembly method of the cast aluminum rotor assembly with built-in magnetic steel includes the following steps:

[0016] 1. Prepare the iron chip: Use a mold to punch the iron chip. The outer circle of the iron chip has a margin of not less than 0.5 mm. The bottom is provided with an inward arc 3 in the middle, and grooves are provided at both ends of the bottom. , two symmetrical process holes 2 are also arranged on the iron chip, and the process holes 2 communicate with the outside through the bottom of the iron chip;

[0017] 2. Riveting the iron chips: the punched iron chips are riveted into iron core parts 1 by riveting screws, and a total of two iron core parts 1 are riveted;

[0018] 3. Assemble the rotor shaft parts: symmetrically set deep holes on the position where the iron core parts are installed on the rotor shaft 4, install two positioning pins 5 on the holes to form the rotor shaft parts, and these two positioning pins 5 ensure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com