Multilayer substrate integration waveguide filter with high out-of-band rejection

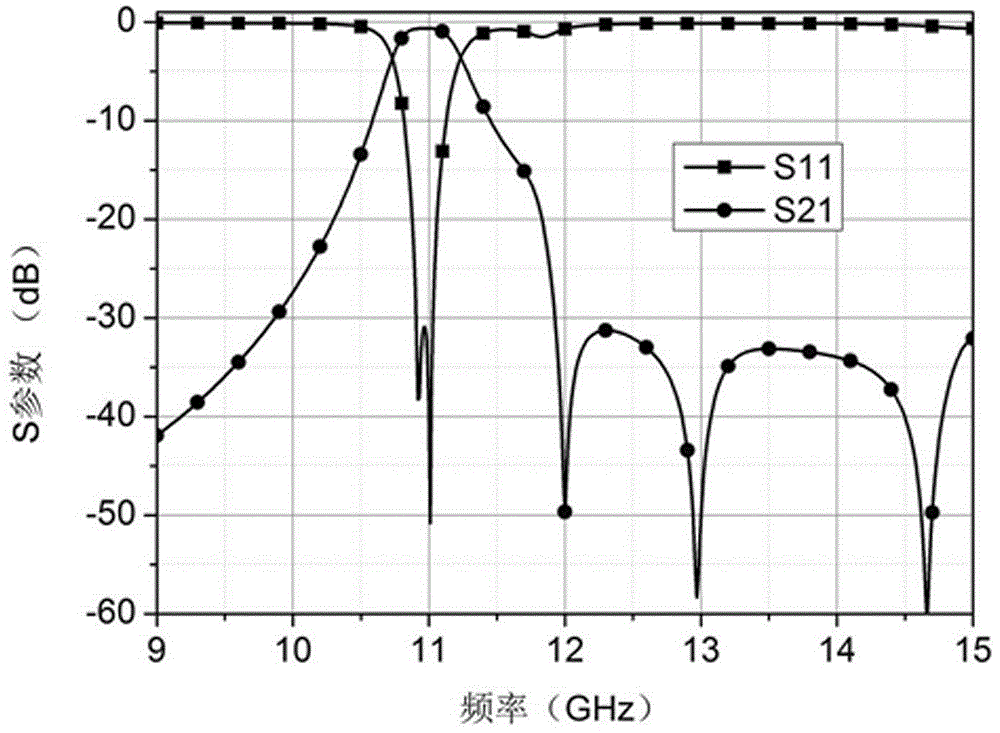

A substrate-integrated waveguide and filter technology, applied in waveguide devices, electrical components, circuits, etc., can solve the problems of large loss, low level of out-of-band suppression, and large size, and achieve low loss and high out-of-band suppression Horizontal, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

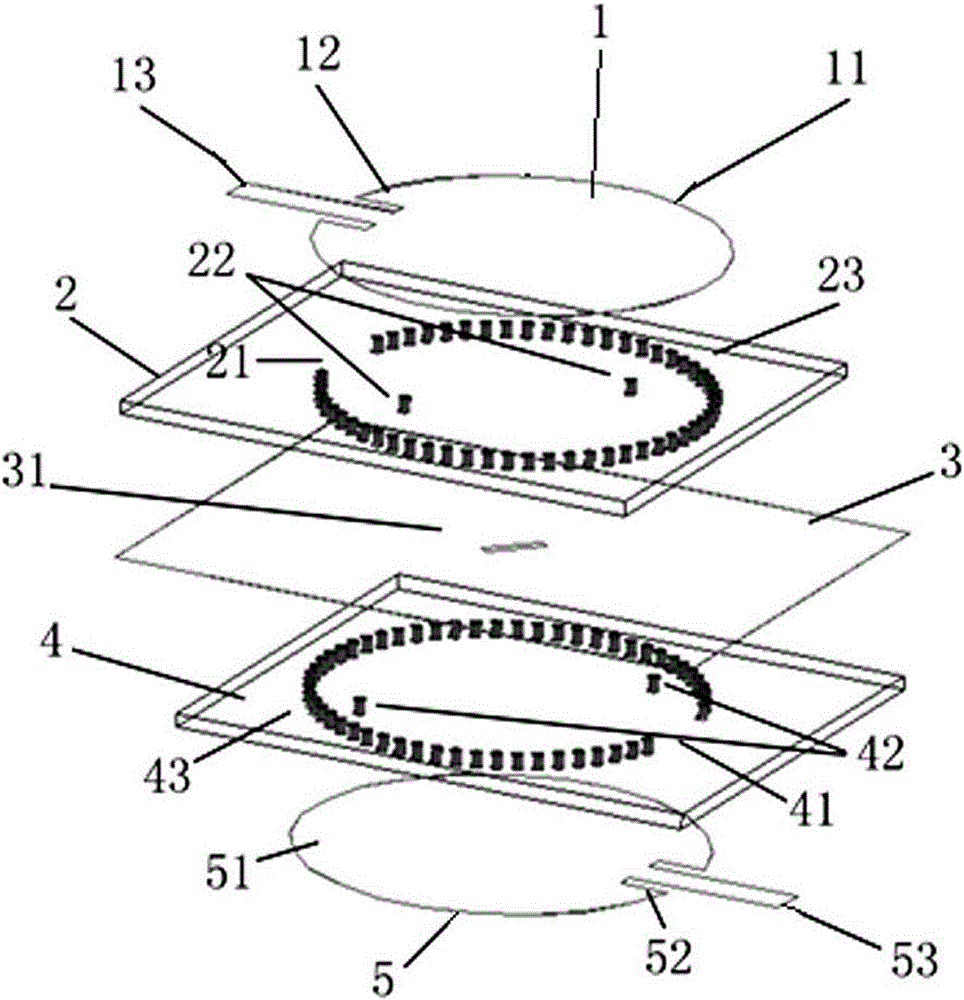

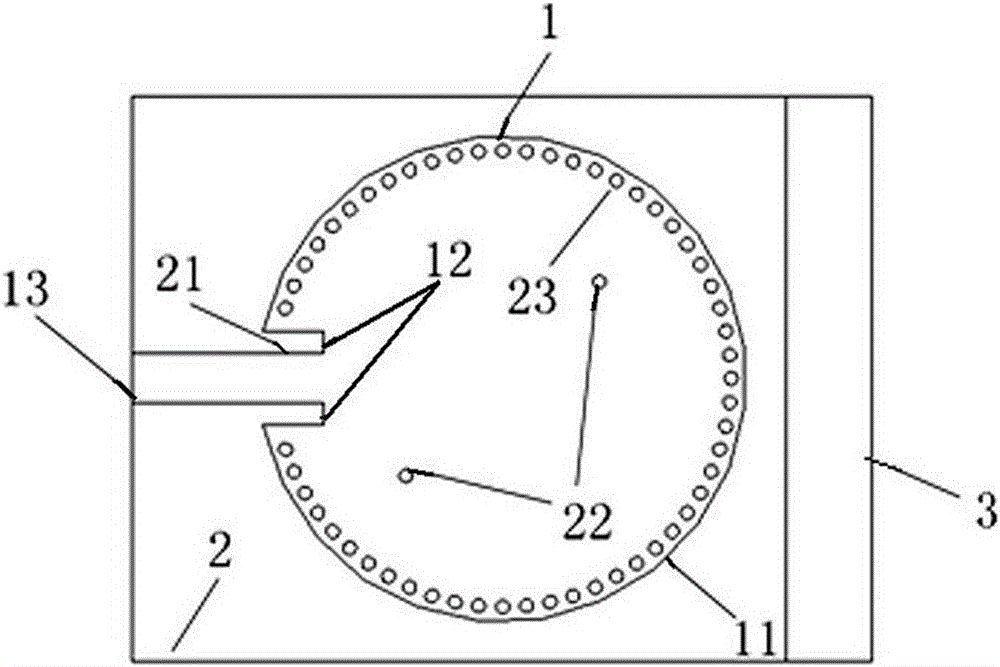

[0018] The present invention will be further described below in conjunction with the drawings and specific embodiments: figure 1 with figure 2 As shown, a multi-layer substrate integrated waveguide filter with high out-of-band suppression includes a first metal layer 1, a first dielectric layer 2, a second metal layer 3, and a second dielectric layer 4 stacked sequentially from top to bottom. , The third metal layer 5, the first, second, and third metal layers 1, 3, 5 are copper foil, the relative dielectric constant of the first and second dielectric layers 2, 4 is 2.65, and the thickness is 0.8mm; A metal layer 1 includes a circular first resonant cavity surface layer 11 and a rectangular first input / output feeder 13 connected to it. The first coupling groove 12 is etched out on the first resonant cavity surface layer 11 and is located at the first input Both sides of the output feeder line 13; the first dielectric layer 2 is rectangular, the first metallized through-hole arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com