Six-axis industrial robot fault diagnosis method and system based on AR model

A fault diagnosis system and technology of industrial robots, applied in the direction of instruments, computer parts, character and pattern recognition, etc., can solve the problems of wide fault location, low fault diagnosis efficiency, difficult real-time monitoring, etc., to solve the problem of difficult fault diagnosis, The effect of improving the efficiency of fault diagnosis and reducing the scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings;

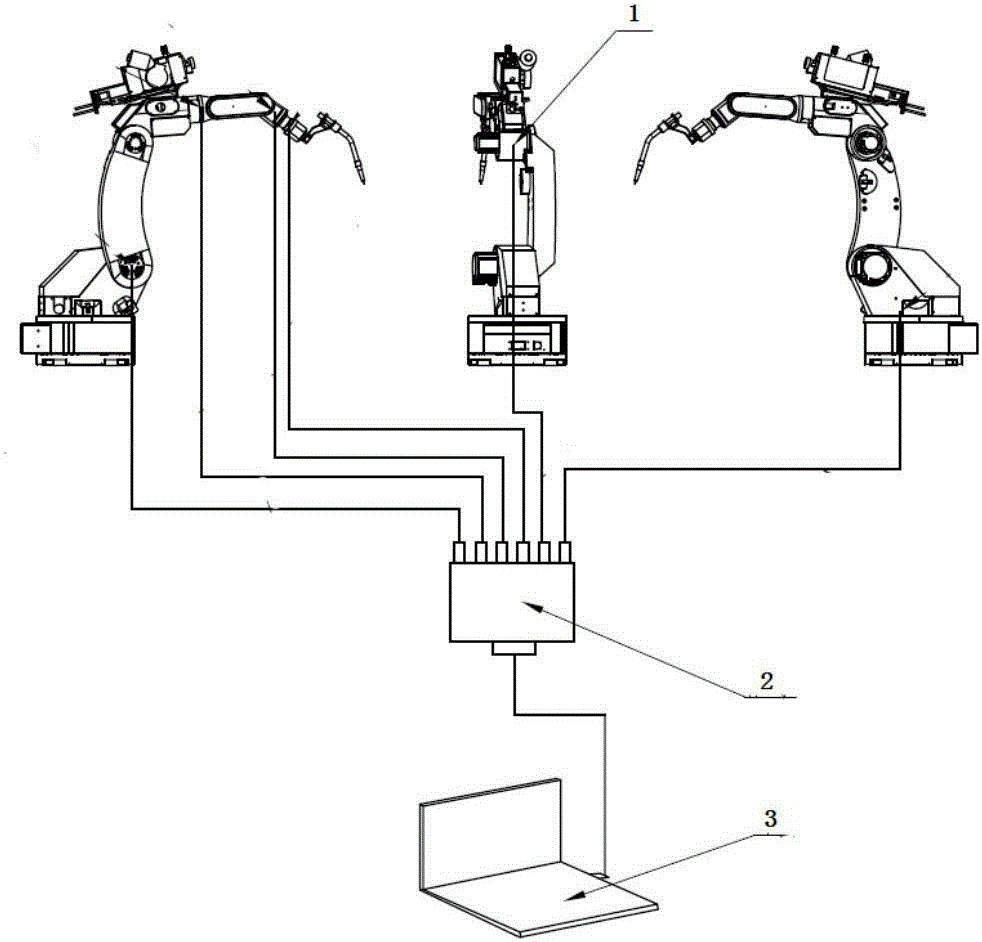

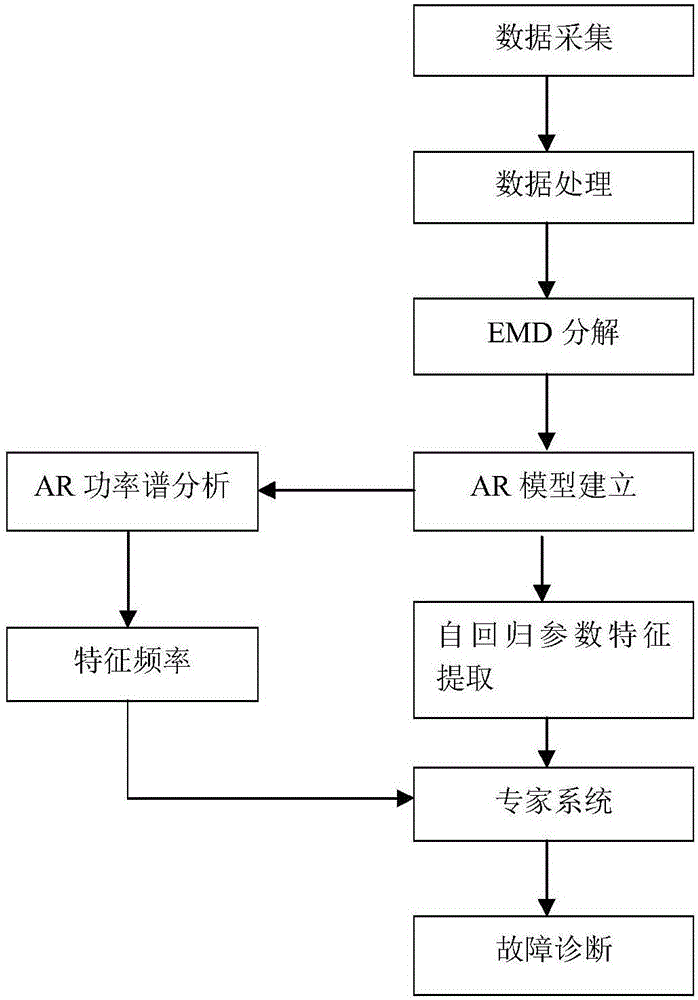

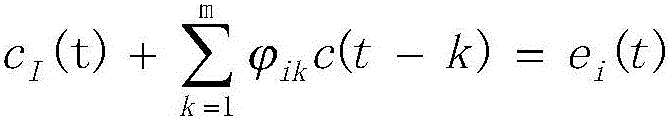

[0022] Such as figure 1 As shown, a six-axis industrial robot fault diagnosis system based on the AR model includes: at a specific operating speed of each axis, six vibration acceleration sensors 1 installed at specific positions transmit vibration signals through signal acquisition cards 2 X(t) is transmitted to the processing device 3, which is a computer in this embodiment. The computer preprocesses the vibration signal X(t) through EMD (Empirical Mode Decomposition, empirical mode decomposition algorithm), and decomposes it into a smooth signal IMF component c with different characteristic scales 1 (t), c 2 (t),...,c n (t); build an autoregressive model AR(m) for any IMF component decomposed by EMD, and extract its model parameters and variance as the fault feature vector unit; use the above-mentioned autoregressive model AR (m) to carry out A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com