Detection method of bent sheet generated by cutting wafer

A detection method and a technology for bending sheets, which are applied in the application of stable bending force to test the strength of materials, measuring devices, and preparation of samples for testing, etc., can solve the problems of inaccuracy, high price, and unsatisfactory effect of cutting wafer curvature. , to achieve the effect of operation, convenient observation and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

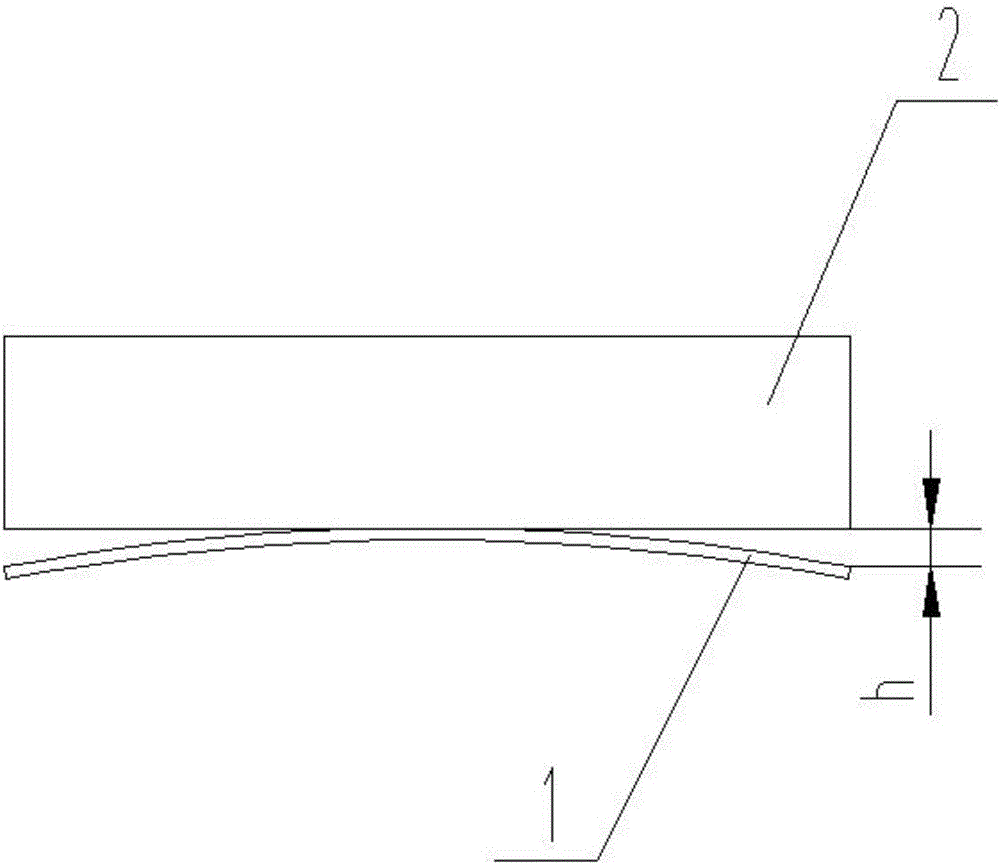

[0022] Such as figure 1 Shown, the present invention comprises the following steps:

[0023] ①. Make a standard block. The height of the standard block is the same as the height of the chip. The length of the standard block is greater than the length of the chip. For the convenience of use, a longer standard block can be made appropriately. The surface of the standard block is processed by a grinding wheel;

[0024] ②. Clean the cut wafers to be tested;

[0025] ③. The standard block and wafer are placed on the working table of the image measuring instrument, and the wafer to be tested is attached to the reference plane of the standard block;

[0026] ④. Adjust the height of the lens that affects the measuring instrument to make the image of the upper edge of the wafer clear;

[0027] ⑤. Use the special tools of the image measuring instrument to measure the gap betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com