Anti-slagging biomass cascade conversion combustion device

A combustion device and biomass technology, applied in the combustion of solid fuel, combustion method, combustion equipment, etc., can solve the problem of easy coking of straw, and achieve the effects of avoiding coke slagging, wide adjustment range and reducing heat flux density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

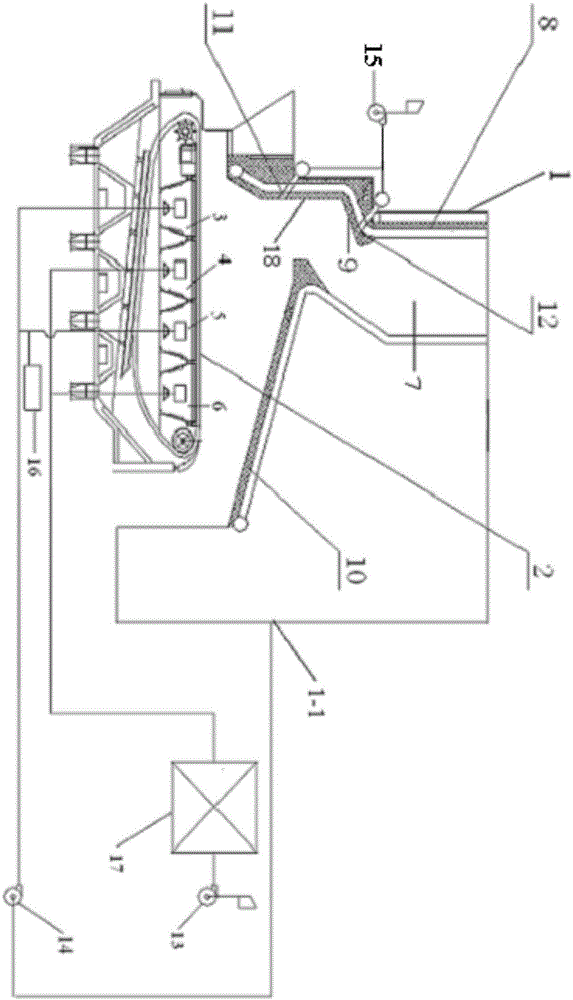

[0025] Specific implementation mode one: as figure 1 , the present embodiment is an anti-slagging biomass cascade conversion combustion device, which is specifically composed of a chain furnace 1, a first blower 13, a second blower 15, a high-temperature induced draft fan 14, a steam generator 16 and an air preheater 17 composition;

[0026] The front arch 9 of the chain furnace 1 is located below the furnace wall 8 above the furnace, and the front arch 9 forms an angle of 20° to 25° with the horizontal direction, so as to strengthen the heat exchange between the high-temperature flue gas and the unburned combustible gas in the furnace. ; The rear arch 10 forms an included angle of 15° to 20° with the horizontal direction, so as to strengthen the heat exchange between the high-temperature flue gas and the coke particles on the surface of the chain grate 2; the bottom of the grate 2 of the chain furnace 1 is arched from the front arch 9 to the rear The direction 10 is the circ...

specific Embodiment approach 2

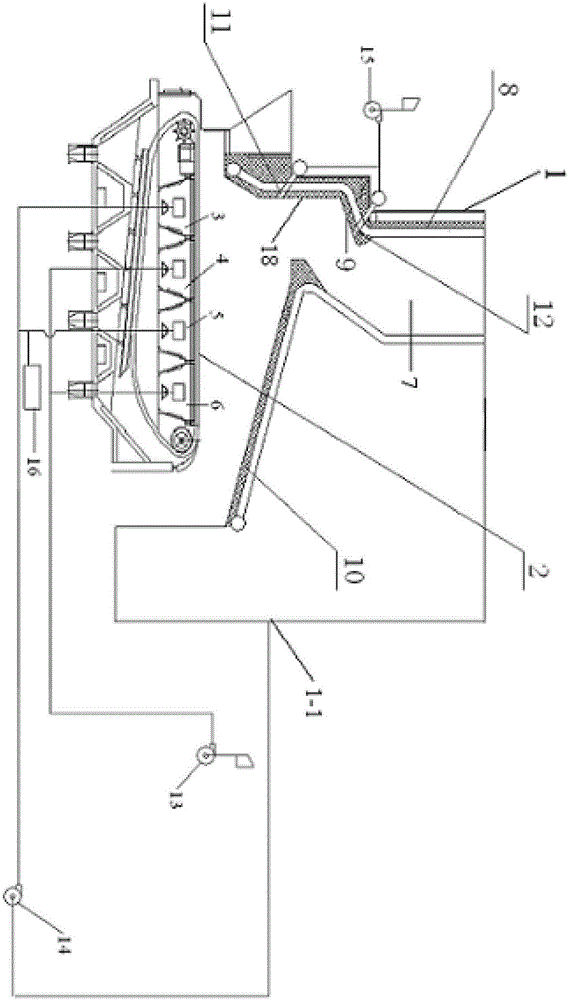

[0040] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the distance between the secondary air nozzle 11 and the fire grate 2 along the height direction of the furnace is 1 meter. Others are the same as the first embodiment.

specific Embodiment approach 3

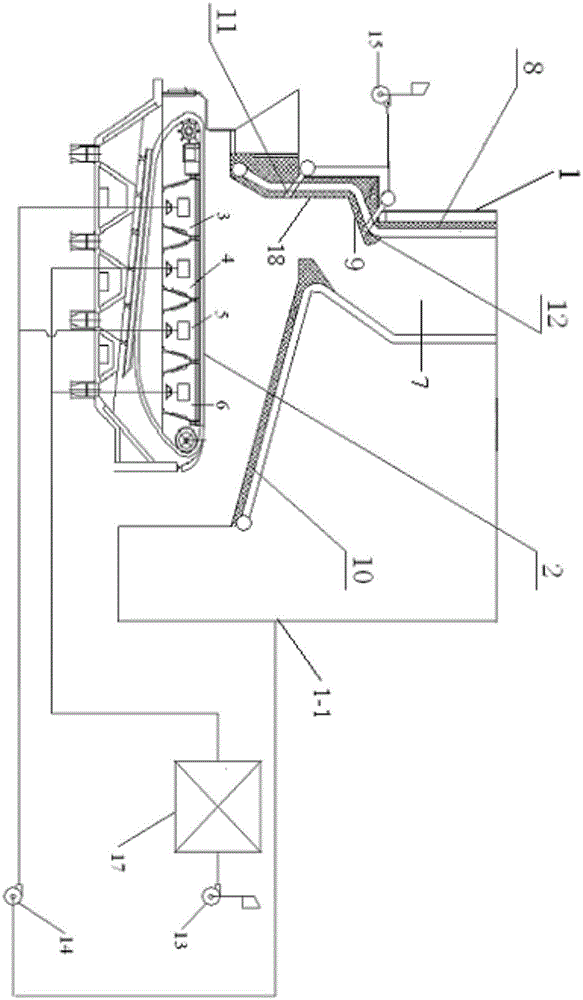

[0041] Specific implementation mode three: as figure 2 , this embodiment is an anti-slagging biomass cascade conversion combustion device, which is different from the specific embodiment 1 in that:

[0042] The water vapor-circulating flue gas chamber 5 communicates with the air outlet of the high-temperature induced draft fan 14, and the air inlet of the high-temperature induced draft fan 14 communicates with the flue outlet 1-1 at the tail of the chain furnace 1. 380°C, the temperature of the coke gasification zone of the control grate 2 is 800°C-850°C; the angle between the rear arch 10 and the horizontal direction is 15°. Others are the same as in the first embodiment.

[0043] In the water vapor-circulating flue gas chamber 5 of this embodiment, water vapor is not used, and only circulating flue gas is used. At this time, the gasification medium of coke is carbon dioxide, and the gasification reaction of coke and carbon dioxide is higher than that of coke and water vapo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com