Multipoint radial jetting oil supply nozzle for high-speed and heavy-load bevel gear

A technology of bevel gears and nozzles, applied in the directions of injection devices, injection devices, gear lubrication/cooling, etc., can solve the problems of large heat generation, ineffective cooling of gear teeth, and large influence of wind resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below by means of specific embodiments:

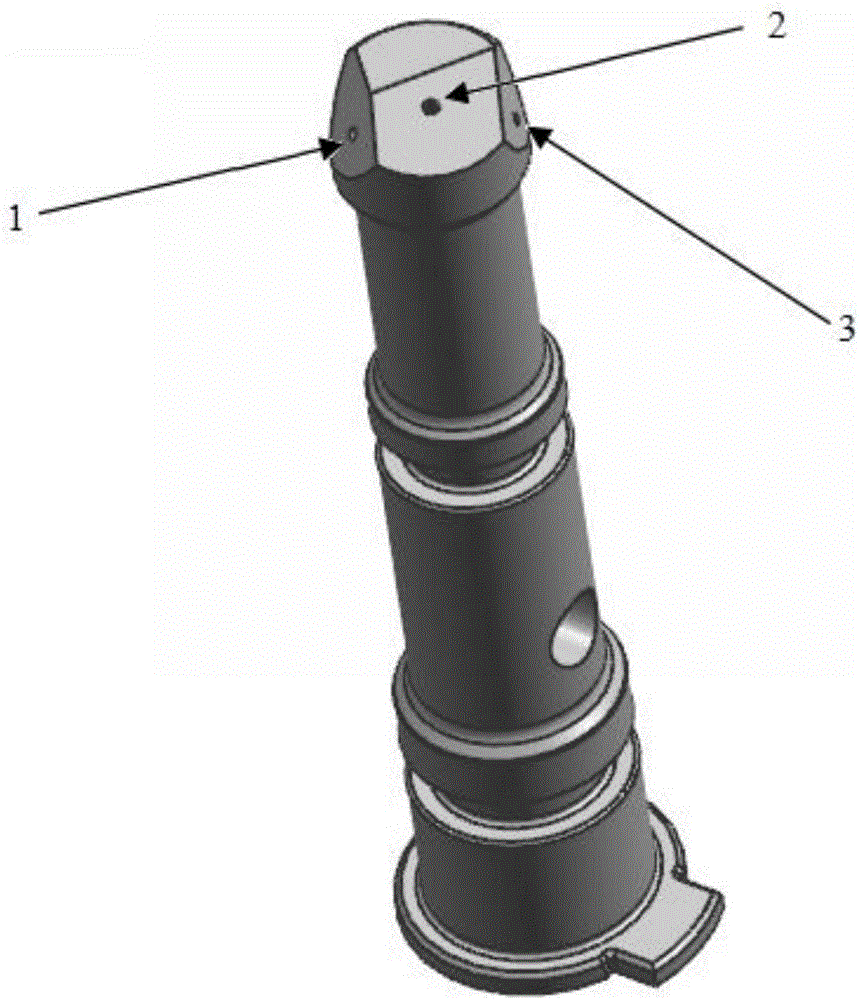

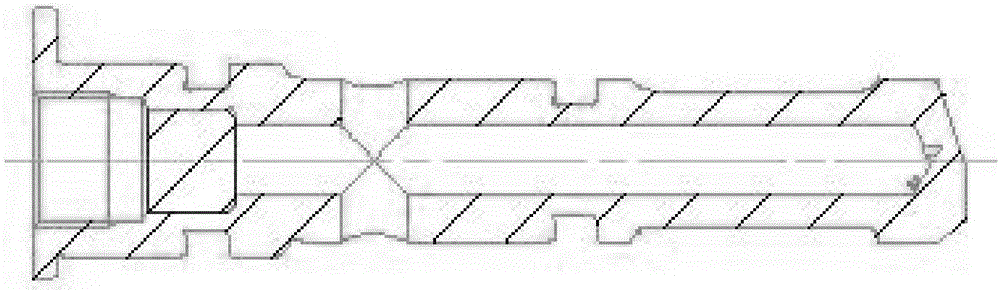

[0027] Such as figure 1 As shown, a multi-point radial injection oil supply nozzle for high-speed heavy-duty bevel gears is provided. The nozzle has a hollow oil chamber, an oil inlet hole and an oil injection hole, and the hollow oil chamber communicates with the oil inlet hole and the oil injection hole. ; A circumferential positioning boss is formed at the end of the fuel injection nozzle; the fuel injection hole includes a first oil injection hole, a second basin oil hole and a third oil injection hole, and the three oil injection holes are all arranged on the injection nozzle the tip of the grease nipple;

[0028] In the axial projection of the nozzle, the projection of the central axis of the nozzle is taken as the origin, and the projected centerline of the circumferential positioning boss is used as the standard projection line. The angle between the centerline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com