High-durability electric fuel pump

An electric fuel pump, durable technology, applied in the direction of pumps, pump components, pump control, etc., can solve the problems of burning out the motor and suction diaphragm, no gasoline cooling in the motor part, easy to block the suction pipe and diaphragm, etc., to achieve The effect of saving time, avoiding high temperature operation, and shortening the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

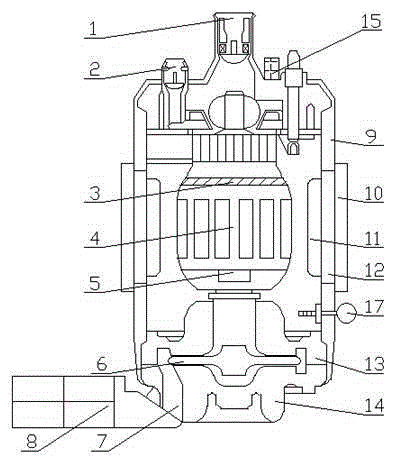

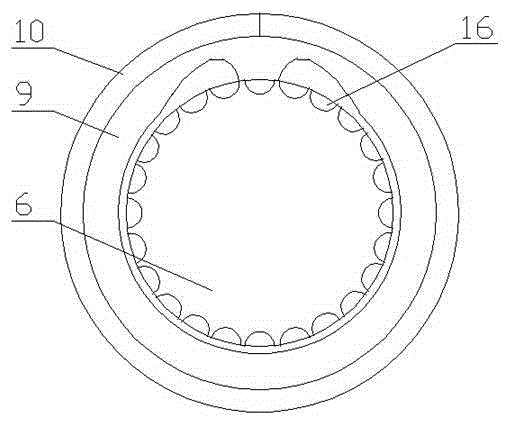

[0011] A high-durability electric fuel pump, including: one-way valve 1, safety valve 2, semiconductor cooling plate 3, motor 4, temperature sensor probe 5, impeller 6, oil inlet 7, filter screen 8, housing 9, sealing strip 10. Magnet 11, slot 12, inner shell 13, pump cover 14, controller 15, vane 16, pressure detection valve 17, check valve 1 is installed on the top of the housing 9, safety valve 2 is installed on one side of check valve 1, single Install the controller 15 on one side of the valve 1, install the motor 4 under the one-way valve 1, install the magnet 11 on both sides of the motor 4, install the slot 12 on the side of the magnet 11, install the sealing strip 10 on the side of the slot 12, and install the bottom of the slot 12 The pressure detection valve 17 is installed, the semiconductor cooling chip 3 is installed on the motor 4, the temperature sensing probe 5 is installed under the semiconductor cooling chip 3, the impeller 6 is installed under the motor 4, t...

Embodiment 2

[0013] When the electric fuel pump is running, the fuel is introduced into the pump from the oil inlet 7, and the filter screen 8 will filter the fuel before it enters the pump, and then the motor 4 drives the impeller 6 to rotate, and the blades 16 on the impeller 6 introduce the fuel into the one-way Valve 1 is discharged after adding a certain pressure. If there is too little fuel and the motor 4 cannot be cooled by fuel, the temperature sensing probe 5 will send a signal to the controller 15 to make the semiconductor cooling chip 3 operate to cool down the motor 4 and avoid the high temperature of the motor 4. The continuous operation under the condition will shorten the service life of the motor 4; when the car is not in use, the sealing strip 10 can be removed, and the slot 12 can be disassembled to clean the inside of the pump to avoid excessive impurities in the pump, which may cause the electric fuel pump to be damaged. The service life is greatly shortened; when check...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com