A method for artificial formation freezing with liquid nitrogen without freezer

A freezing method and freezer technology, applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of delay in emergency rescue, time-consuming and laborious, and many processed parts, and achieve the goal of improving construction progress, reducing costs, and saving materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0026] The present invention provides a liquid nitrogen artificial formation freezing method without a freezer, aiming at the disadvantages of many procedures, many processing parts, and time-consuming and labor-intensive problems in the existing method for freezing the formation with a liquid nitrogen freezer.

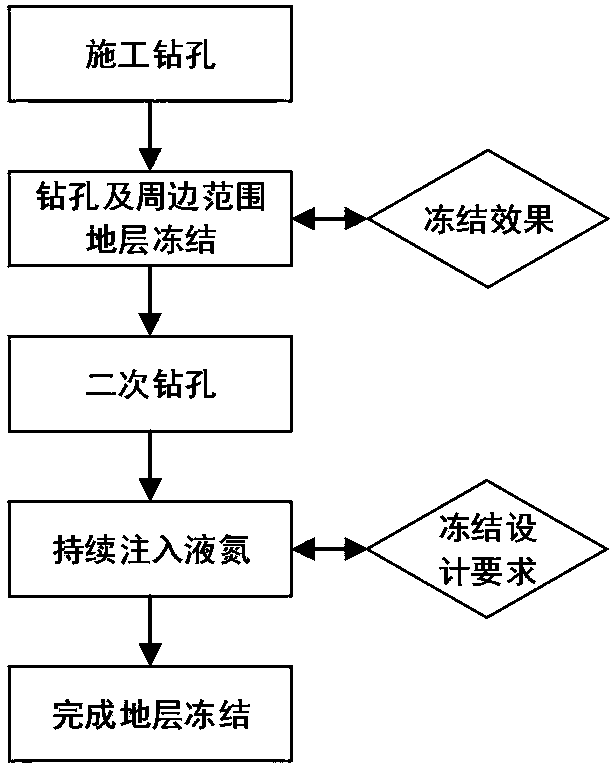

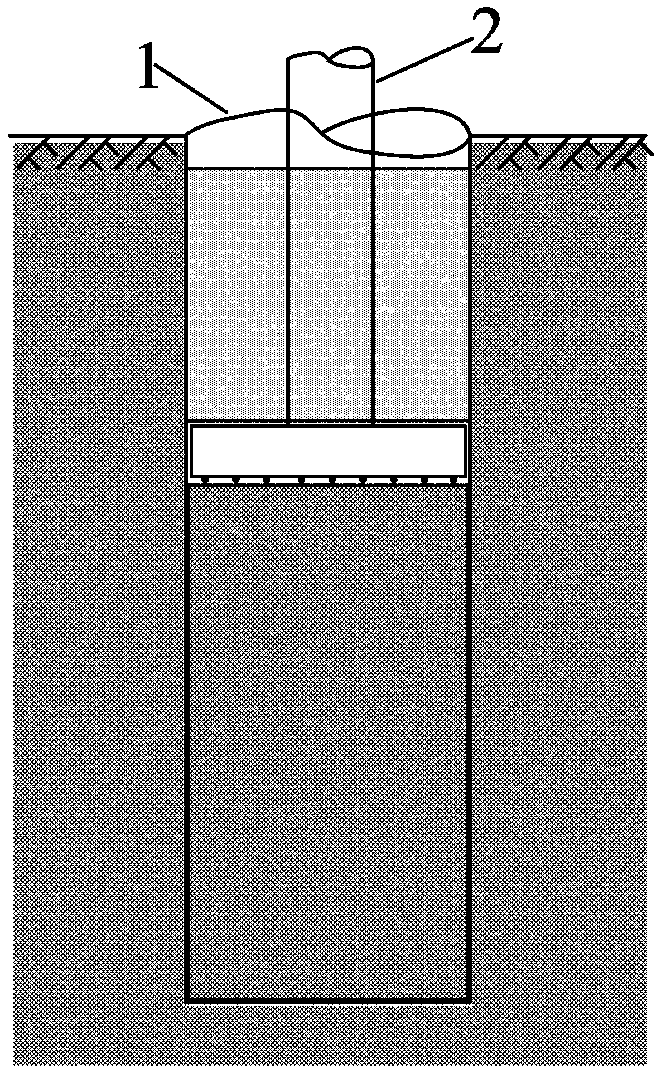

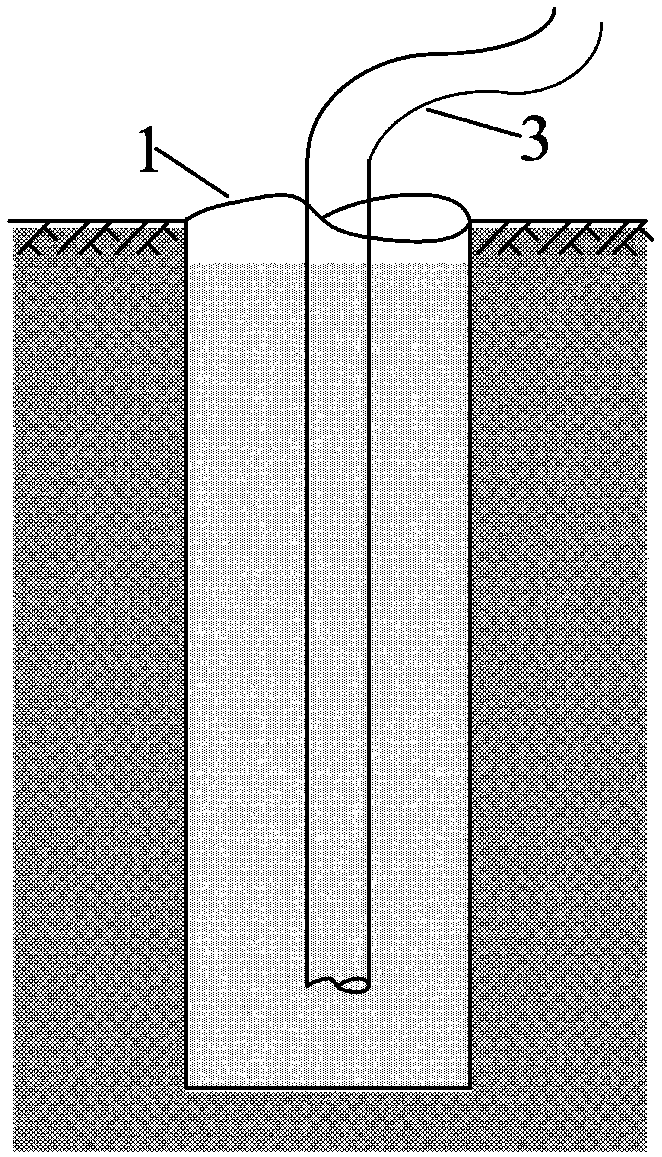

[0027] Such as figure 1 As shown, the method includes construction drilling, that is, primary drilling; formation freezing of the drilling hole and surrounding areas; secondary drilling construction; continuous injection of liquid nitrogen to freeze the formation; completion of freezing and other steps. The specific implementation process is as follows:

[0028] A shield tunneling method reinforcement project adopts the liquid nitrogen formatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com