Antibacterial soap and preparation method thereof

An antibacterial soap and raw material technology, applied in the field of daily chemical cleaning products, can solve the problems of adverse effects of decontamination ability, great harm to human skin, and irritation of skin mucous membranes, etc., and achieves relieving dry skin, significant bacteriostatic effect, and strong decontamination effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

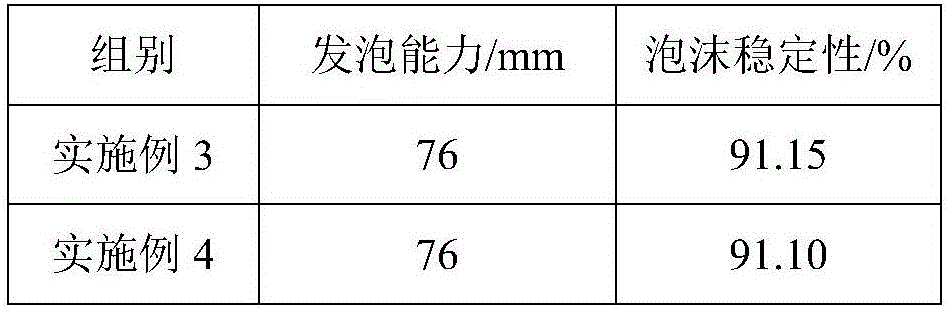

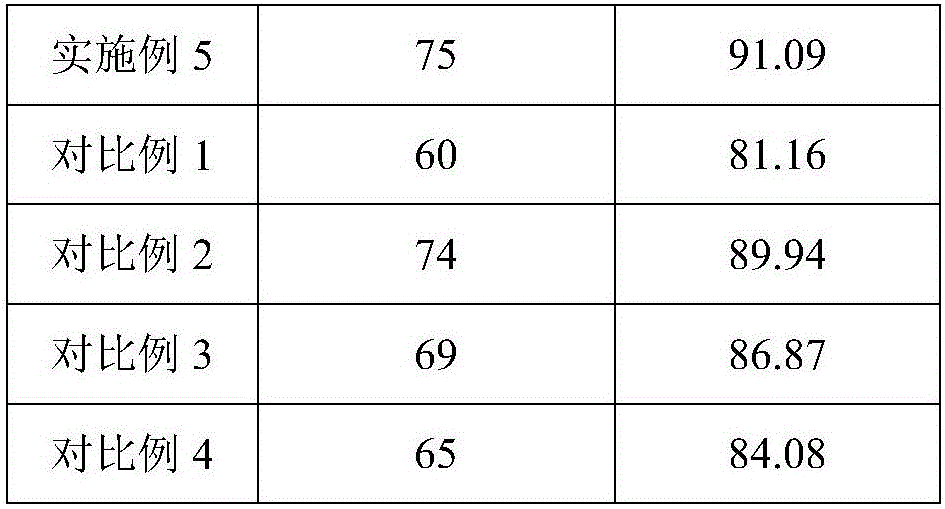

Examples

Embodiment 1

[0032] Example 1 Preparation of Folium Artemisiae Argyi Essential Oil

[0033] (1) Get fresh Artemisia argyi leaves and wash, dry naturally for 15 days, then pulverize, pass through a 50-mesh sieve to obtain Artemisia sylvestris coarse powder;

[0034] (2) Carry out three-stage molecular distillation of Artemisia argyi leaf coarse powder, wherein the step of first-order molecular distillation is specifically: add Artemisia argyi leaf coarse powder in feeder, each 200g, feed rate is 1.2g / min, then open vacuum pump, Control the vacuum degree of 120Pa, open the constant temperature oil tank of the feeder, preheat the coarse powder of mugwort leaves, and then open the constant temperature oil tank of the distillation main body, control the distillation temperature within 50°C, and keep the vacuum degree within the range of 65Pa, and start the scraping system , the film distillation scraper speed is controlled at 250r / min, and the distillation time is 2h, wherein, the light compone...

Embodiment 2

[0035] Example 2 Preparation of tea tree essential oil

[0036] (1) Wash the fresh tea leaves, dry them naturally for 15 days, then pulverize them, and pass through a 50-mesh sieve to obtain coarse tea powder;

[0037] (2) Put tea coarse powder and distilled water in a 2000mL round-bottomed flask after being mixed with a material-to-liquid ratio of 1:40, heat in a microwave oven for 5 minutes, and the microwave power is 600W, then add a small amount of zeolite, and place in a simultaneous distillation extraction device One end is heated with a temperature-controllable electric heating mantle, and the other end of the device is added to a 250mL round-bottomed flask with 50mL of petroleum ether, and a small amount of zeolite is heated in a constant temperature water bath with a water bath temperature of 45°C. ether extract;

[0038] (3) Add anhydrous sodium sulfate to the petroleum ether extract, seal it, place it in a -10°C refrigerator overnight, filter, and use a rotary evapor...

Embodiment 3

[0039] Embodiment 3 antibacterial soap preparation

[0040] The antibacterial soap of Example 3 of the present invention is made up of the preparation raw material of following parts by weight: 20 parts of sodium palmitate, 20 parts of sodium myristate, 15 parts of sodium laurate, 12 parts of fatty alcohol polyoxyethylene ether sodium sulfate, vegetable essential oil 3 parts, 8 parts of sugar esters, 3 parts of glycerin, 1 part of sodium chloride, 4 parts of pullulan, 0.5 parts of 2,6-di-tert-butyl-4-methylphenol, 1 part of disodium edetate 5 parts of essence, 0.3 part of pigment, 0.2 part of preservative, and the balance is deionized water;

[0041] Wherein, plant essential oil is that the Artemisia argyi quintessence oil and the tea tree essential oil that embodiment 1 and 2 make respectively form with the weight ratio of 1:1;

[0042] The sugar ester is composed of octenyl succinic acid glucose ester and octadecenyl succinic acid starch sugar ester in a weight ratio of 4:1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com