A kind of production and processing technology of refined snake oil

A processing technology and snake oil technology, applied in the production and processing technology field of refined snake oil, can solve the problems of no application, limited and the like, and achieve the effects of good deodorization performance, simple process and easy cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

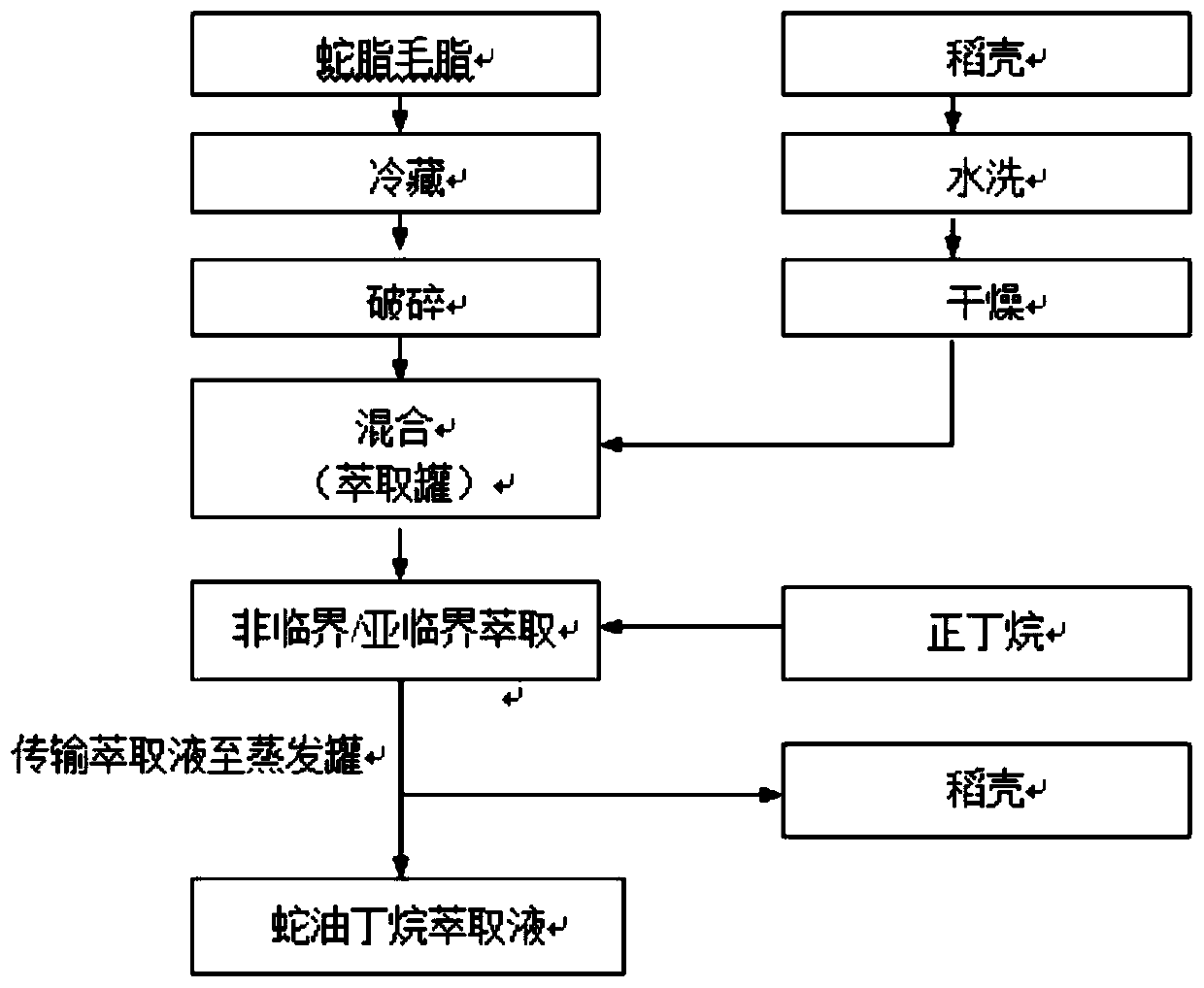

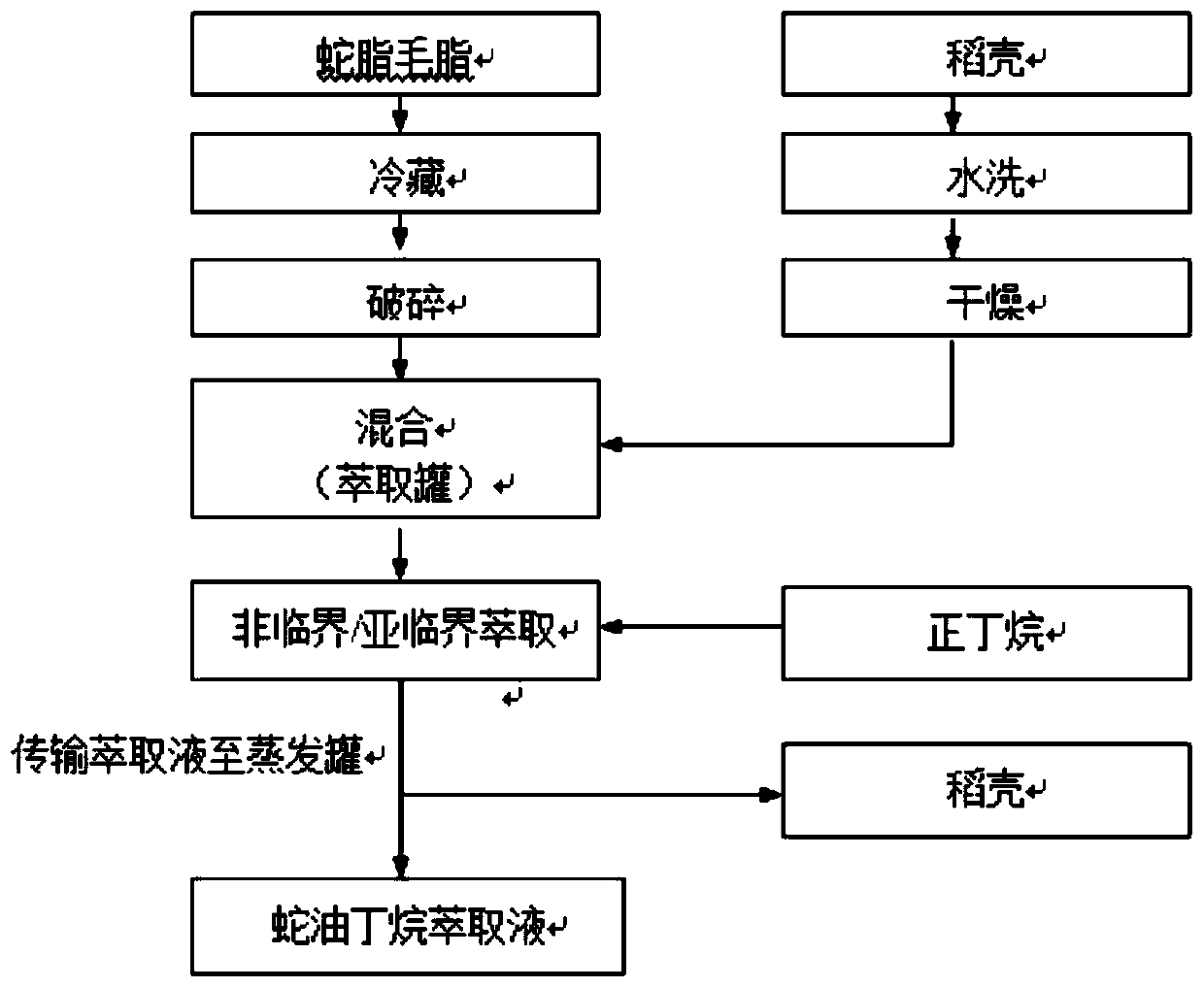

[0040] The production and processing technology of embodiment 1 refining snake oil

[0041] 1) Pretreatment: collect 90kg of snake fat and hair fat, refrigerate at 0-4°C, and crush to obtain small meat-like particles;

[0042] 2) Mixing: Mix the small particles of meat powder and rice husk in a weight ratio of 1:4 to obtain a mixture;

[0043] 3) Non-critical fluid extraction: Add n-butane to the mixture for extraction, the extraction pressure is 6MPa, the extraction temperature is 38°C, and the stirring speed is 35rpm; stand still for 45min to obtain n-butane extract;

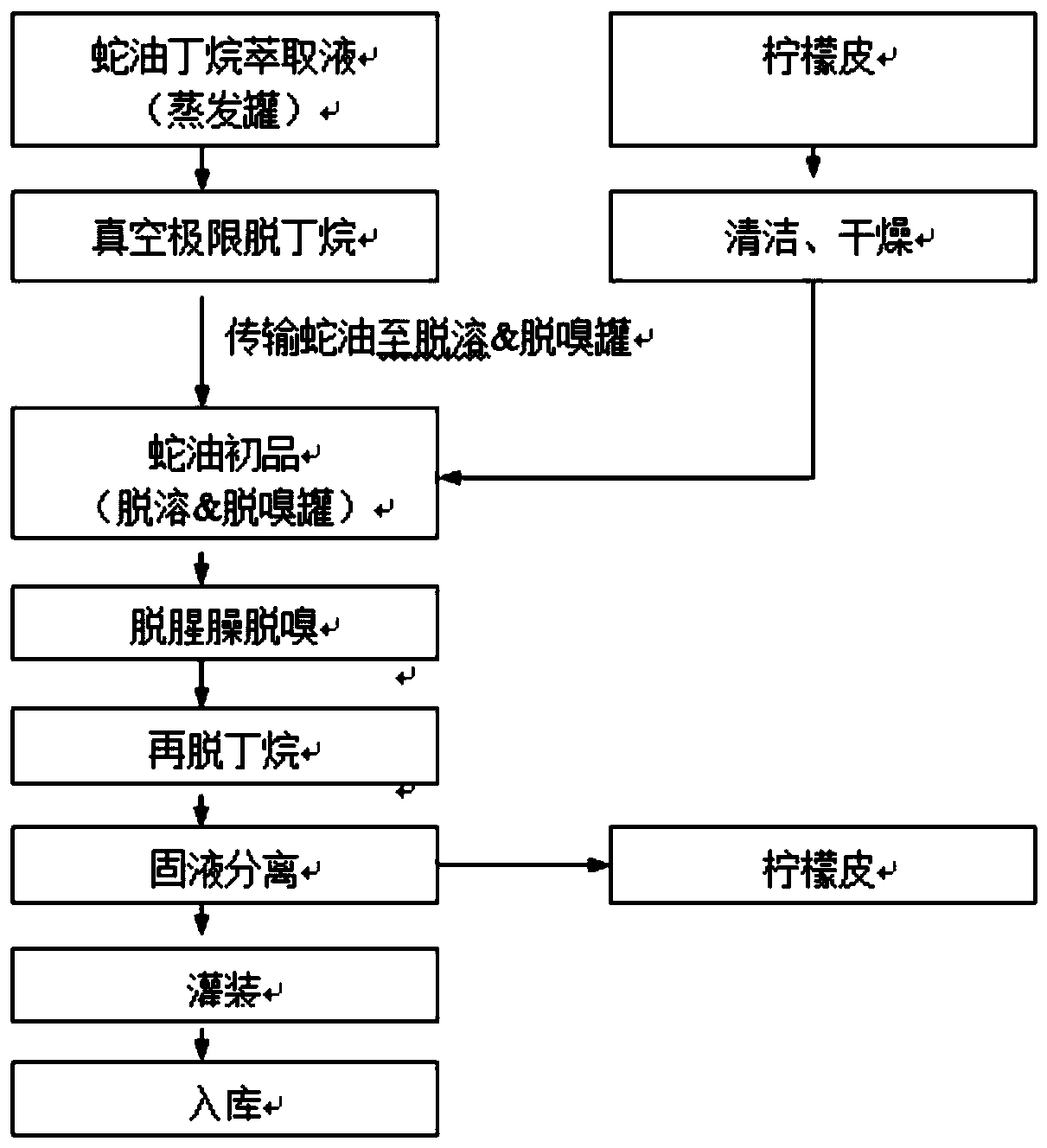

[0044] 4) Vacuum limit de-butanization: collect the n-butane extract and transfer it to the evaporation tank for evaporation. The vacuum degree in the evaporation tank is -0.1MPa, the solution temperature in the evaporation tank is 55°C, and the desolvation time is 50 minutes. Evaporate to obtain Primary products of snake oil; residual n-butane ≤ 300mg / kg;

[0045] 5) Transfer to the desolvation and deodoriz...

Embodiment 2

[0049] The production and processing technology of embodiment 2 refining snake oil

[0050] 1) Pretreatment: collect 90kg of snake fat and wool fat, refrigerate at 0°C to 4°C, and crush to obtain small meat-like particles;

[0051] 2) Mixing: Mix the small particles of meat powder and rice husk in a weight ratio of 1:1 to obtain a mixture;

[0052] 3) Non-critical fluid extraction: add n-butane to the mixture for extraction, the extraction pressure is 1MPa, the extraction temperature is 20°C, and the stirring speed is 40rpm; stand still for 30min to obtain n-butane extract;

[0053] 4) Vacuum limit de-butanization: collect the n-butane extract and transfer it to the evaporation tank for evaporation. The vacuum degree in the evaporation tank is -0.8MPa, the solution temperature in the evaporation tank is 55°C, and the desolvation time is 60 minutes. Evaporate to obtain Primary products of snake oil; residual n-butane ≤ 300mg / kg;

[0054] 5) Transfer to the desolventizing and ...

Embodiment 3

[0058] The production and processing technology of embodiment 3 refining snake oil

[0059] 1) Pretreatment: collect 89kg of snake fat hair grease, refrigerate at 0°C to 4°C, and crush to obtain small meat-like particles;

[0060] 2) Mixing: Mixing small meat-like particles and rice husks in a weight ratio of 1:8 to obtain a mixture;

[0061] 3) Non-critical fluid extraction: add n-butane to the mixture for extraction, the extraction pressure is 10MPa, the extraction temperature is 50°C, and the stirring speed is 30rpm; stand still for 60min to obtain n-butane extract;

[0062] 4) De-butanization by vacuum limit: collect the n-butane extract and transfer it to the evaporation tank for evaporation. The vacuum degree in the evaporation tank is -0.5MPa, the solution temperature in the evaporation tank is 52°C, and the desolventization time is 40 minutes. Evaporate to obtain Primary products of snake oil; residual n-butane ≤ 300mg / kg;

[0063] 5) Transfer to the desolventizing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com