Polishing agent and method for polishing gallium antimonide wafer by employing polishing agent

A technology of polishing liquid and gallium antimonide, which is applied in the field of polishing liquid, can solve the problems of uneven thickness of gallium antimonide substrate material, chipping and slag removal on the surface of the substrate, scratches, etc., and achieves less human control factors and no chipping. The effect of edge slag removal and improved availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

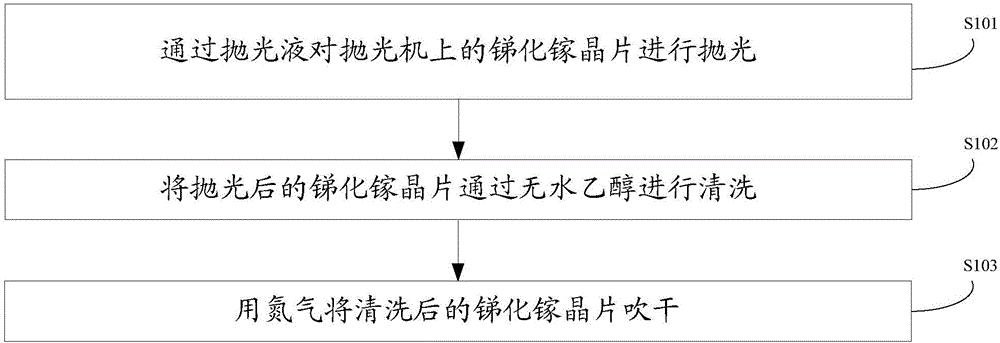

[0043] Example 1: A type containing SiO 2 Abrasive suspending weakly acidic and alkaline bottom liquid, adding hydrogen peroxide as an oxidizing agent, adding a small amount of glacial acetic acid formula, put the pre-treated gallium antimonide substrate with a thickness of 454 microns, put it on a general polishing machine, and polish it The rotation speed is 40rpm, and the polishing pressure is 100g / cm 2 , add 22℃, 12% SiO 2 In the mixed polishing liquid of abrasive + 7% hydrogen peroxide + 0.7% glacial acetic acid, the drop rate of the polishing liquid is 12ml / min, the polishing time is 30mins, and then cleaned with absolute ethanol and blown dry with nitrogen. After polishing, the gallium antimonide substrate is removed by 94 microns, and the surface of the gallium antimonide is smooth and flat.

example 2

[0044] Example 2: A type containing SiO 2 Abrasive suspending weakly acidic and alkaline base liquid, adding hydrogen peroxide as an oxidizing agent, adding a small amount of lactic acid formula, put the pre-treated gallium antimonide substrate with a thickness of 480 microns on a general polishing machine, and the polishing speed 40rpm, polishing pressure 110g / cm 2 , adding 26°C, 13% SiO 2 In the mixed polishing liquid of abrasive + 8% hydrogen peroxide + 3% lactic acid, the drop rate of the polishing liquid is 15ml / min, the polishing time is 20mins, and then cleaned with absolute ethanol and blown dry with nitrogen. After polishing, the gallium antimonide substrate is removed by 83 microns, and the gallium antimonide surface is smooth and flat.

example 3

[0045] Example 3: A type containing SiO 2 Abrasive suspending weakly acidic and alkaline bottom liquid, adding hydrogen peroxide as an oxidizing agent, adding a small amount of lactic acid formula, put the pre-treated gallium antimonide substrate with a thickness of 425 microns on a general polishing machine, and the polishing speed 50rpm, polishing pressure 120g / cm 2 , add 25℃, 14% SiO 2 In the mixed polishing solution of abrasive + 10% hydrogen peroxide + 4% lactic acid, the drop rate of the polishing solution is 15ml / min, the polishing time is 20mins, and then cleaned with absolute ethanol and blown dry with nitrogen. After polishing, the gallium antimonide substrate is removed by 95 microns, and the surface of the gallium antimonide is smooth and flat.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com