Automobile sun visor composite materialand preparation method thereof

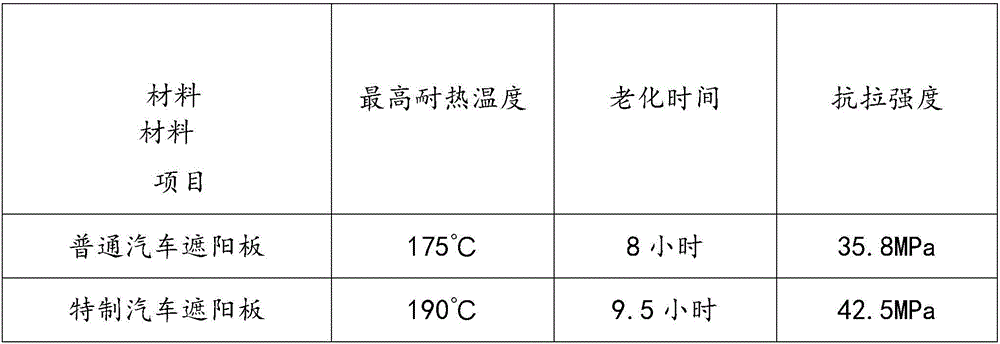

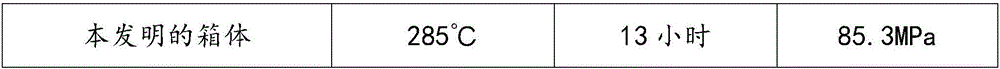

A technology of automobile sun visor and composite material, which is applied to the composite material of automobile sun visor and its preparation field, can solve the problems of poor anti-aging effect of sun visor, short service life and low heat resistance temperature, etc., and achieve anti-aging effect. Good, high tensile strength, high heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A composite material for an automobile sun visor, which is made of the following materials in parts by weight, including 35 parts of polyurethane, 20 parts of polyphenylene sulfide, 14 parts of boron fiber, 18 parts of aramid fiber, 6 parts of silicon carbide fiber, 7 parts of polyester resin, 8 parts of phenolic resin, 13 parts of polysulfide rubber, 8 parts of epoxy group, 2 parts of acrylate, 5 parts of N-tert-butyl-2-benzothiazole sulfenamide, 10 parts of xanthate 8 parts, 8 parts of phthalates, 2 parts of ethylene-vinyl acetate copolymer, 6 parts of sorbitol monopalmitate, 12 parts of benzotriazole, 17 parts of lauric acid and 4 parts of iron oxide red.

[0018] A method for preparing a composite material of an automobile sun visor, comprising the following steps:

[0019] 1) 35 parts of polyurethane, 20 parts of polyphenylene sulfide, 14 parts of boron fiber, 18 parts of aramid fiber, 6 parts of silicon carbide fiber, 7 parts of polyester resin, 8 parts of phenoli...

Embodiment 2

[0024] A composite material for an automobile sun visor, which is made of the following materials in parts by weight, including 37.5 parts of polyurethane, 22.5 parts of polyphenylene sulfide, 15 parts of boron fiber, 19 parts of aramid fiber, 8.5 parts of silicon carbide fiber, 9.5 parts of polyester resin, 9 parts of phenolic resin, 14 parts of polysulfide rubber, 11 parts of epoxy group, 4 parts of acrylate, 6.5 parts of N-tert-butyl-2-benzothiazole sulfenamide, 13 parts of xanthate 9 parts of phthalates, 5.5 parts of ethylene-vinyl acetate copolymer, 6.5 parts of sorbitol monopalmitate, 14 parts of benzotriazole, 19.5 parts of lauric acid and 6.5 parts of iron oxide red.

[0025] A method for preparing a composite material of an automobile sun visor, comprising the following steps:

[0026] 1) 37.5 parts of polyurethane, 22.5 parts of polyphenylene sulfide, 15 parts of boron fiber, 19 parts of aramid fiber, 8.5 parts of silicon carbide fiber, 9.5 parts of polyester resin, ...

Embodiment 3

[0031] A composite material for an automobile sun visor, which is made of the following materials in parts by weight, including 40 parts of polyurethane, 25 parts of polyphenylene sulfide, 16 parts of boron fiber, 20 parts of aramid fiber, 11 parts of silicon carbide fiber, 12 parts of polyester resin, 10 parts of phenolic resin, 15 parts of polysulfide rubber, 14 parts of epoxy group, 6 parts of acrylate, 8 parts of N-tert-butyl-2-benzothiazole sulfenamide, 16 parts of xanthate 10 parts of phthalates, 9 parts of ethylene-vinyl acetate copolymer, 7 parts of sorbitol monopalmitate, 16 parts of benzotriazole, 22 parts of lauric acid and 9 parts of iron oxide red.

[0032] A method for preparing a composite material of an automobile sun visor, comprising the following steps:

[0033] 1) 40 parts of polyurethane, 25 parts of polyphenylene sulfide, 16 parts of boron fiber, 20 parts of aramid fiber, 11 parts of silicon carbide fiber, 12 parts of polyester resin, 10 parts of phenolic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com