Nonionic surfactant modified montmorillonite and preparation method thereof

A non-ionic surface, montmorillonite technology, applied in chemical instruments and methods, non-metallic elements, inorganic chemistry, etc., can solve the problem of insufficient energy required for bond formation, low hydration degree of montmorillonite, and inability to realize non-ionic Surfactant intercalation modification of montmorillonite and other issues, to achieve the effect of great application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The specific implementation steps are as follows:

[0029] (1) Get 10g montmorillonite and disperse it in water, configure the montmorillonite dispersion that mass concentration is 2.0%;

[0030] (2) adding octylphenol polyoxyethylene ether with 30% montmorillonite quality to the montmorillonite dispersion, and stirring and reacting for 115min at an ultrasonic power of 120W and a reaction temperature of 70°C to obtain a reaction product;

[0031] (3) washing the reaction product obtained in step (2), and then drying at 60° C. for 24 hours;

[0032] (4) Grinding the dried product obtained in step (3) until 97% passes through a 200-mesh sieve to obtain nonionic surfactant-modified montmorillonite.

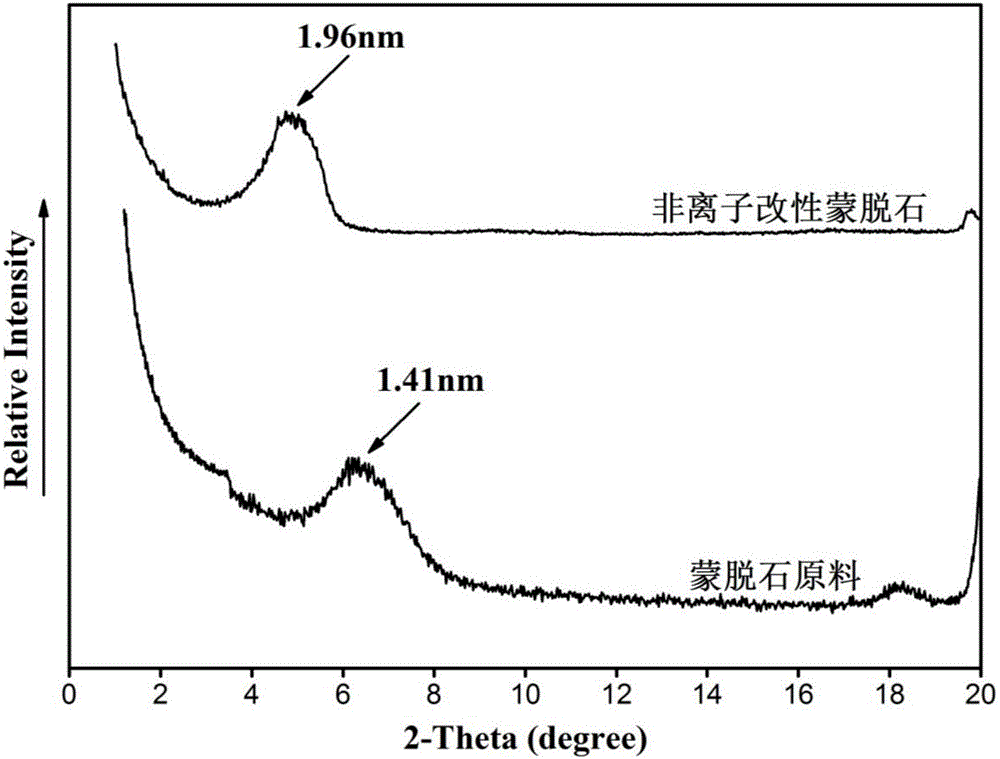

[0033] The XRD comparison chart of the nonionic surfactant modified montmorillonite prepared in Example 1 and the raw material montmorillonite is shown in the attached figure 1 . Depend on figure 1 It can be seen that the interlayer spacing of the bottom surface of the non...

Embodiment 2

[0035] Same as step in embodiment 1, difference is: the mass concentration of montmorillonite dispersion liquid is 2.5% in the step (1); In the step (2), the add-on of fatty alcohol polyoxyethylene ether (AEO-9) is 35% of the mass of montmorillonite, the ultrasonic power is 160W, the reaction temperature is 60°C, and the ultrasonic time is 95min;

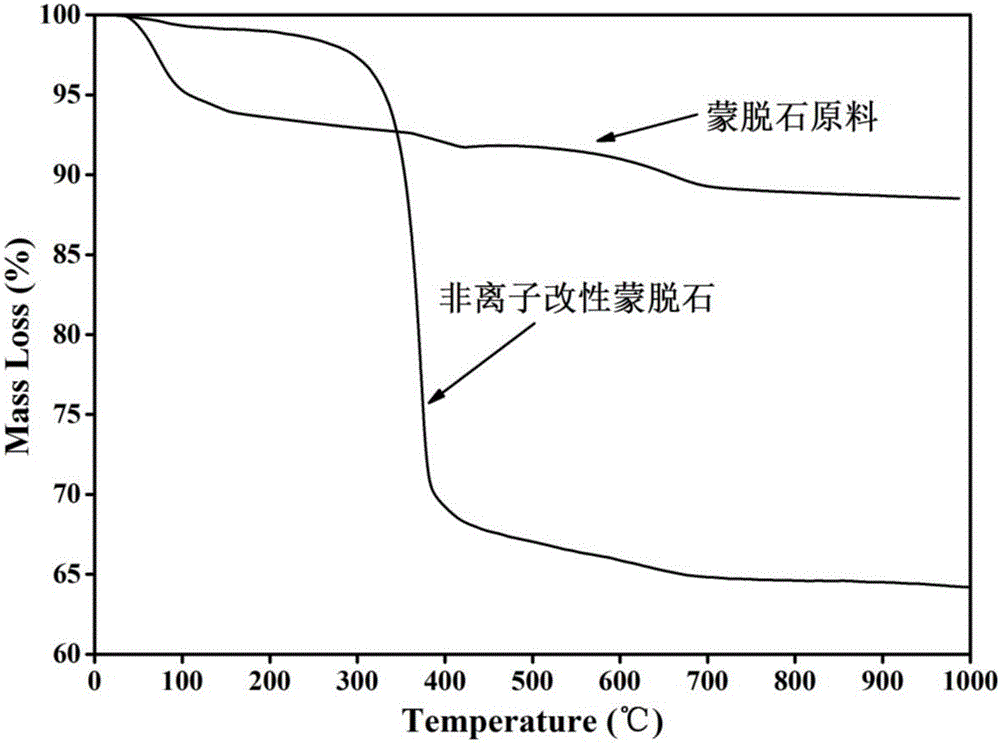

[0036] The TG comparison chart of the nonionic surfactant modified montmorillonite prepared in Example 2 and the raw material montmorillonite is shown in the attached figure 2 . Depend on figure 2 It can be seen that the organic carbon content of nonionic surfactant modified montmorillonite increases.

Embodiment 3

[0038] Same as step in embodiment 1, difference is: the mass concentration of montmorillonite dispersion is 3.0% in the step (1); Adding of polyoxyethylene sorbitan fatty acid ester (Tween20) in the step (2) The amount is 40% of the mass of montmorillonite, the ultrasonic power is 200W, the reaction temperature is 50°C, and the ultrasonic time is 75min;

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com