Electrified railway contact line counter weight device

A technology of electrified railways and counterweight devices, which is applied in the direction of overhead lines, etc., can solve problems such as excessive curve force and contact wire lead height, etc., and achieve the effect of convenient installation, high technical standard requirements, and ingenious ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in combination with specific embodiments.

[0022] To solve the problem of excessive vertical upward force component of the contact wire caused by too high curve force, the method of reducing the tension of the contact wire is generally adopted, but this method will increase the sag of the contact wire and reduce the technical standard of the catenary, resulting in Potential safety hazards have certain limitations.

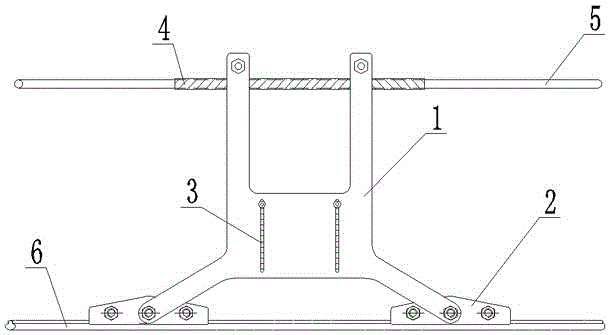

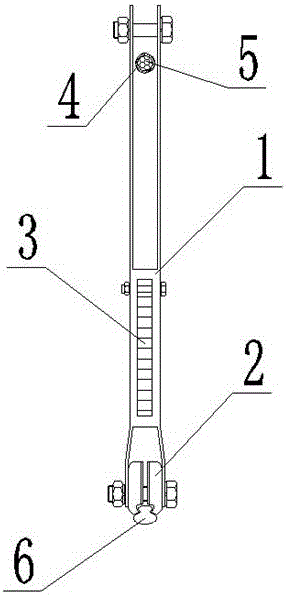

[0023] The present invention relates to a contact wire counterweight device for electrified railways, which includes a contact wire counterweight box 1 in the shape of a lower splayed H, and a counterweight weight 3 is placed in the middle box. The upper end of the contact wire counterweight box 1 is dynamically controlled by the catenary cable, and can move up and down. The piercing bolts arranged on the top of the U-shaped clip can prevent the contact line counterweight box from falling off from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com