Highly protective polyimide flame-retardant garment fabric and heat setting method thereof

A technology of polyimide and polyimide fiber, which is applied in the direction of fabric surface trimming, heating/cooling fabric, textile, etc., can solve the problem of not being able to meet the shaping requirements of polyimide fabric, the time is short, and the contact temperature is low and other problems, to achieve the effect of increasing the contact surface, small internal stress and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A high-protection polyimide flame-retardant clothing fabric, which is sewn by a combination of inner and outer layers of fabrics, the inner layer is woven from polyimide fiber yarn and polyimide filaments, The outer layer is a cloth surface with raised grids woven from polyimide fiber yarn and polyimide filament, the specification of the polyimide fiber yarn is 40S, and the polyimide fiber yarn The specification of the filament is 300D.

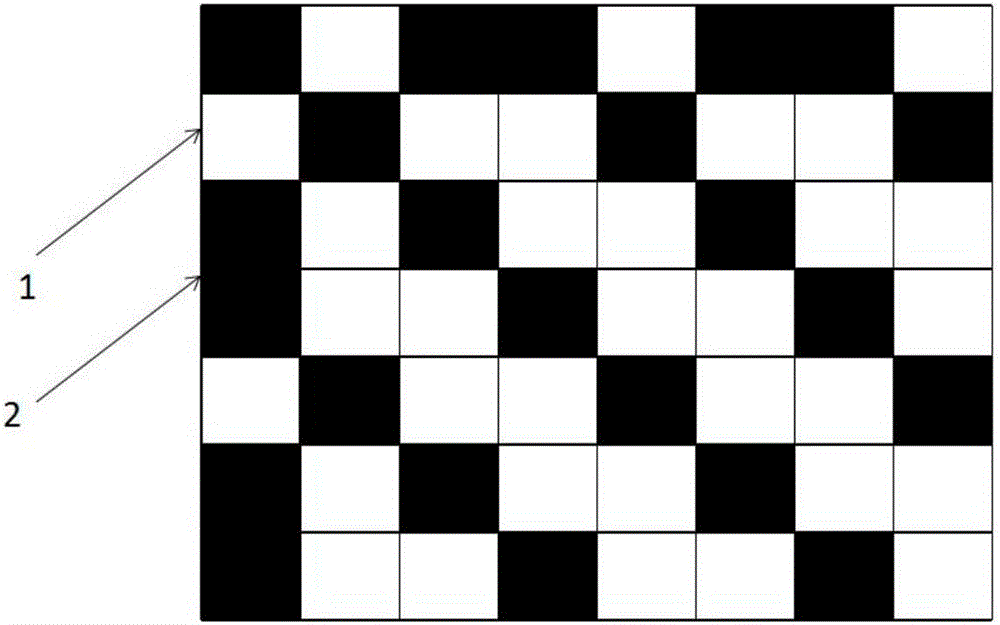

[0021] The weaving method of the outer fabric of the high-protection polyimide flame-retardant clothing is: select polyimide fiber yarn 40S, polyimide filament 300D according to figure 1 Weaving into woven fabrics, in which area 1 is designed according to the satin weave, and a polyimide filament is incorporated in area 2, so that through yarns and filaments of different thicknesses, a lattice fabric with raised weave points is formed , increasing the contact surface of the fabric.

[0022] The heat-setting process of the high-protec...

Embodiment 2

[0024] A high-protection polyimide flame-retardant clothing fabric, which is sewn by a combination of inner and outer layers of fabrics, the inner layer is woven from polyimide fiber yarn and aramid filaments, the The outer layer is a cloth surface with raised lattice woven by polyimide fiber yarn and aramid filament, the specification of the polyimide fiber yarn is 36S, and the specification of the aramid filament is 300D .

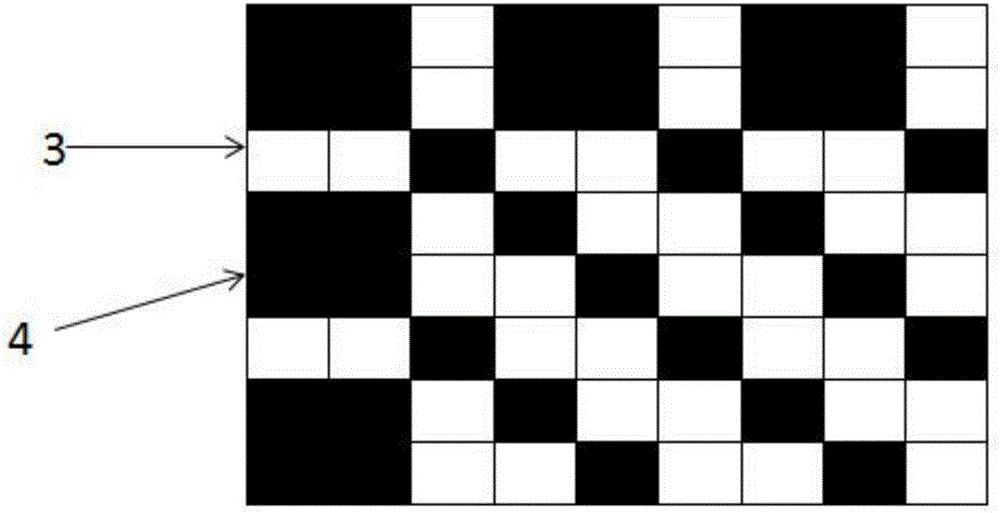

[0025] The weaving method of the outer fabric of the high-protection polyimide flame-retardant clothing is: select polyimide fiber yarn 36S, aramid filament 300D according to figure 2 Woven into a woven fabric, wherein the area 3 is designed according to the satin weave, and a polyimide fiber yarn and an aramid filament are incorporated in the area 4. Through the yarns and filaments of different thicknesses, a convex pattern is formed. The lattice fabric with organized points increases the contact surface of the fabric and makes the fabric form a uniqu...

Embodiment 3

[0028] A high-protection polyimide flame-retardant clothing fabric, which is sewn by a combination of inner and outer layers of fabrics, the inner layer is woven from polyimide fiber yarn and aramid filaments, the The outer layer is a cloth surface with raised lattice woven by polyimide fiber yarn and aramid filament, the specification of the polyimide fiber yarn is 23S, and the specification of the aramid filament is 300D .

[0029] The weaving method of the outer fabric of the high-protection polyimide flame-retardant clothing is: select polyimide fiber yarn 23S, aramid filament 300D according to figure 2 Woven into woven fabrics, in which area 3 is designed according to the satin weave, and two aramid filaments are incorporated in area 4, and a lattice fabric with raised weave points is formed through yarns and filaments of different thicknesses, increasing the The contact surface of the fabric makes the fabric form a unique style.

[0030] The heat-setting process of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com