Wood anti-cracking agent

An anti-cracking agent and wood technology, applied in the direction of wood impregnation, impregnated wood, wood processing equipment, etc., can solve the problems of abrasion of the treatment layer, poor weather resistance, durability, damage to wooden furniture, etc., and achieve simple process and simple use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

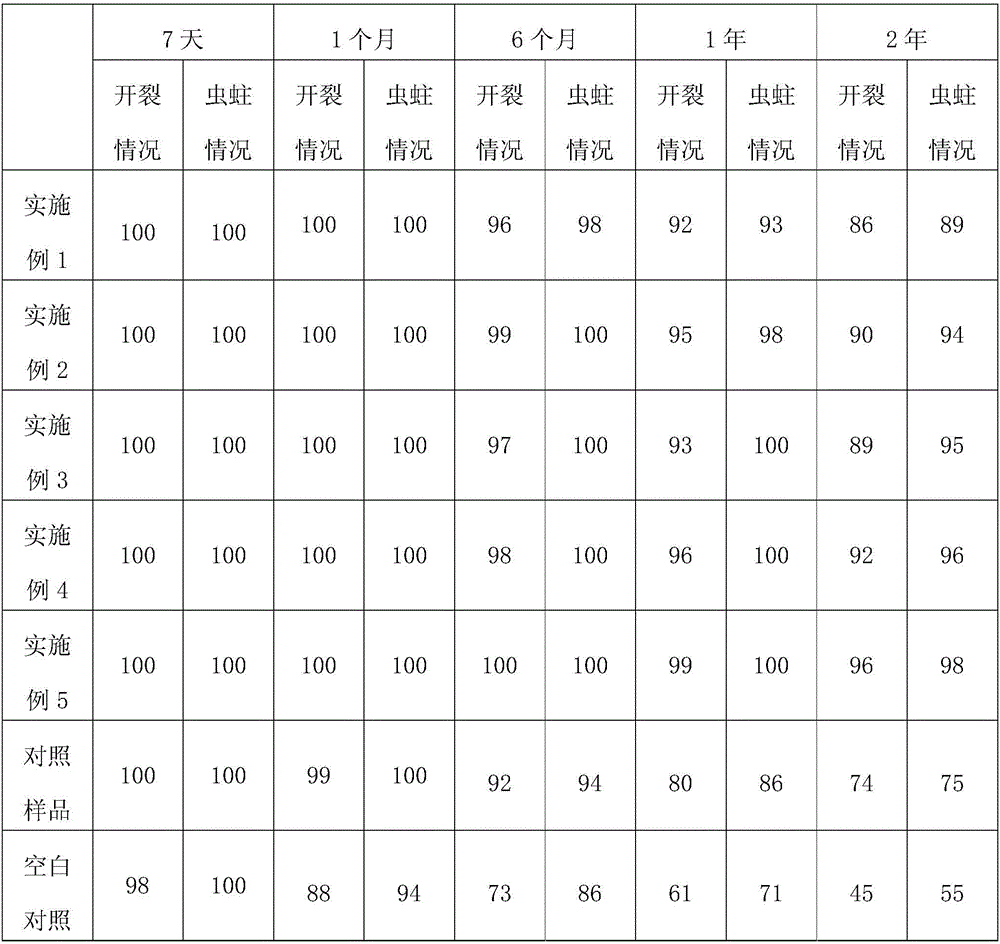

Examples

Embodiment 1

[0029] A kind of anti-cracking agent for wood, it is made up of the following raw materials in weight ratio: 30 parts of palm oil, 25 parts of pine oil, 15 parts of catalpa oil, 20 parts of tung oil, 10 parts of beeswax, 0.5 part of methylparaben, 10 parts of silicone oil , 1 part of polyvinyl alcohol, 1 part of glycerin, 2 parts of Tween, 4 parts of cobalt isooctanoate, 0.5 part of neem oil and 0.2 part of allicin.

[0030] Example 1

[0031] A kind of anti-cracking agent for wood, it is made up of the following raw materials in weight ratio: 55 parts of palm oil, 40 parts of pine oil, 30 parts of catalpa oil, 35 parts of tung oil, 20 parts of beeswax, 2.5 parts of methylparaben, 20 parts of silicone oil , 5 parts of polyvinyl alcohol, 5 parts of glycerin, 6 parts of Tween, 10 parts of cobalt isooctanoate, 2.5 parts of neem oil and 1.0 part of allicin.

Embodiment 3

[0033] A kind of wood anti-cracking agent, is made up of the raw material of following weight ratio: palm oil 35 parts, pine oil 30 parts, catalpa oil 20 parts, tung oil 25 parts, beeswax 13 parts, methylparaben 1 part, silicone oil 13 parts , 2 parts of polyvinyl alcohol, 2 parts of glycerin, 3 parts of Tween, 5 parts of cobalt isooctanoate, 1 part of neem oil and 0.4 part of allicin.

[0034] Example 3

[0035] A kind of wood anti-cracking agent, is made up of the raw material of following weight ratio: palm oil 50 parts, pine oil 35 parts, catalpa oil 25 parts, tung oil 30 parts, beeswax 17 parts, methylparaben 1.5 parts, silicone oil 17 parts , 4 parts of polyvinyl alcohol, 4 parts of glycerin, 5 parts of Tween, 9 parts of cobalt isooctanoate, 2 parts of neem oil and 0.8 parts of allicin.

Embodiment 5

[0037] A kind of anti-cracking agent for wood, it is made up of the following raw materials in weight ratio: palm oil 42 parts, pine oil 32.5 parts, catalpa oil 22.5 parts, tung oil 27 parts, beeswax 15 parts, methylparaben 1.2 parts, silicone oil 15 parts , 6 parts of polyvinyl alcohol, 3 parts of glycerin, 4 parts of Tween, 7 parts of cobalt isooctanoate, 1.5 parts of neem oil and 0.6 parts of allicin.

[0038] Two, preparation embodiment

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com