Special anti-blockage die-casting die for automobile casting

A die-casting mold and anti-jamming technology, which is used in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as prolonged production time, easy occurrence of material jams, product surface cracks, etc., to avoid manual application and avoid wasting time. , the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

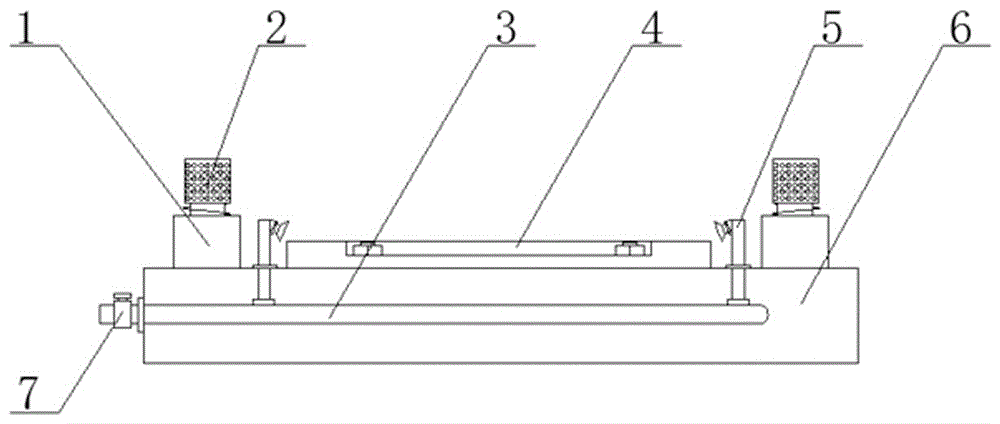

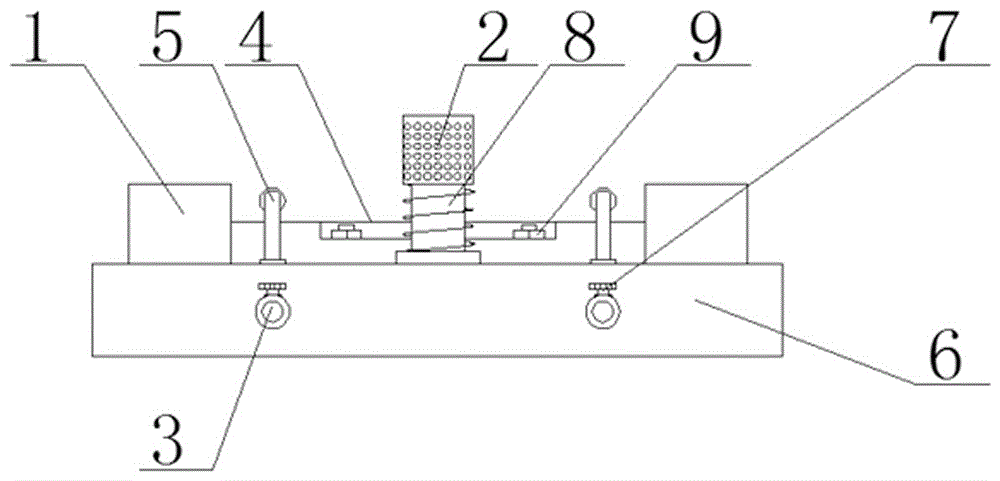

[0015] See figure 1 with figure 2 , The present invention provides a technical solution: a special anti-blocking die-casting mold for automobile casting, including a lower mold base 6, a conveying pipe control valve 7 and a guide post return spring 8. The upper two ends of the lower mold base 6 are both set The limit protection column 1 is provided with a lower mold guide column 2 on the lower mold base 6 near the rear of the limit prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com