Packing box board glue brushing machine

A glue brushing machine and packaging box technology, which is applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve the problems of sufficient supply of goods, failure to supply customers, and the inability to use equipment to realize the glue brushing of packaging boxes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

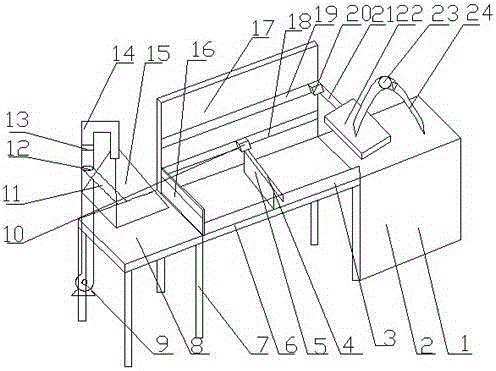

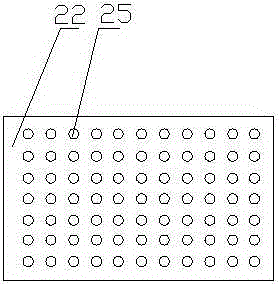

[0028] like figure 1 As shown, one side of the first slider 10 and the second slider 20 are respectively provided with a connecting rod 4 and a fixed rod 21, the lower end of the connecting rod 4 is equipped with a brush 5, and one side of the fixed rod 21 is provided with Spray plate 22.

[0029] In the present invention, through the first slider 10 and the second slider 20, it is convenient to control the spraying glue and laying glue on the designated place of the packaging box, and the brush 5 is installed on the connecting rod 4, which is convenient when the brush cannot be used. , remove it.

Embodiment 2

[0031] like figure 1 As shown, the spray plate 22 is connected to the glue storage box 2 through a feed pipe 24, and a pump 23 is installed in the feed pipe 24.

Embodiment 3

[0033] like figure 1 As shown, a support rod 11 and a fixing ring 12 arranged on one side of the support rod 11 are provided on one side of the second workbench 8 .

[0034] In the present invention, the air duct 14 can be fixed through the fixing ring 12 on one side of the support rod 11, so as to facilitate drying of the packaging box.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com