Dust-electrical-charge bag dust collector

A bag dust collector and dust charging technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of power loss, poor regeneration effect of filter bags, and low life of filter bags, reaching the number of damages Reduce, easy to clean dust, reduce the effect of operating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0025] The following examples are used to illustrate the present invention, but cannot be used to limit the protection scope of the present invention. The conditions in the examples can be further adjusted according to specific conditions.

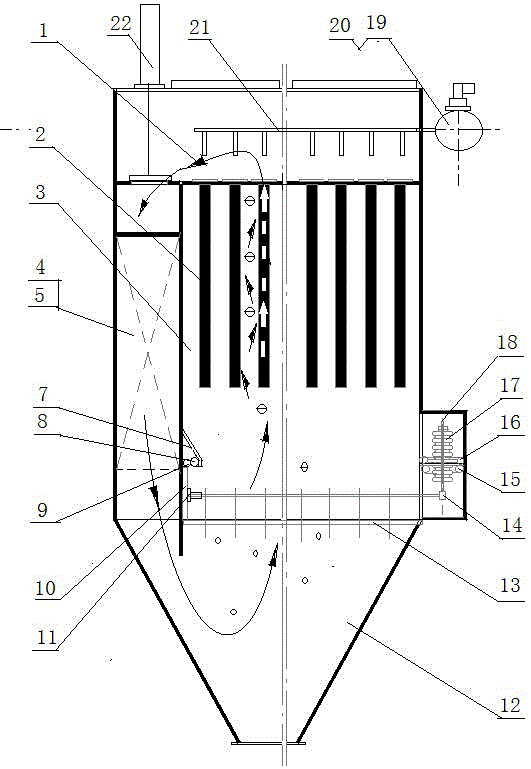

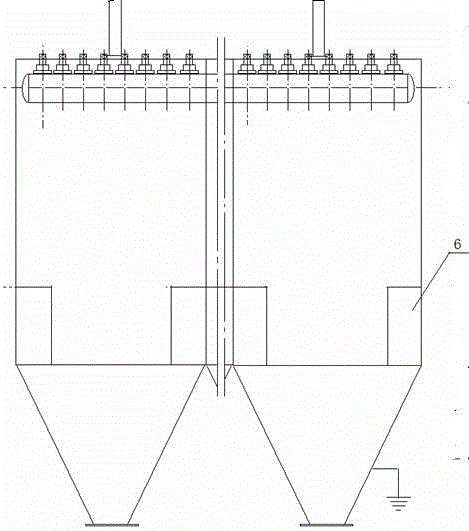

[0026] The structure of the bag filter adopts the dust removal form of double row or single row low pressure pulse on-line or offline, and can also adopt the form of double row or single row air box type dust removal. This embodiment takes the single row low pressure pulse offline dust removal bag filter as an example , detailing the specific design scheme of its dust-charged bag filter.

[0027] The structure of dust charged bag filter see figure 1 , figure 2 . The single chamber of the dust collector is an inverted pyramid structure, and the inverted pyramid is divided into three parts: the clean air chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com