Processing method of non-additive germinated quinoa and brown rice noodles

A technology without additives and processing methods, applied in the field of food processing, can solve the problems of reduced quality of noodles and insufficient nutrition, and achieve the effects of improving the nutritional status and edible quality of grains, being easy to dissolve and absorb, and improving human health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The noodles are made of the following raw materials in parts by weight: 100 parts by weight of flour, 20 parts by weight of quinoa slurry, and 28 parts by weight of brown rice slurry, and are prepared through the following process:

[0027] 1. Production of slurry:

[0028] 1) Selection of quinoa: choose grains with uniform and full grain shape, bright and whitish color, good integrity, few broken grains and no impurities;

[0029] 2) Selection of brown rice: choose grains with uniform and full grain shape, smooth film, no spots, yellow embryo color and no impurities;

[0030] 3) Germination of quinoa: Soak the selected quinoa in water at 28°C for 8 hours, then take it out and place it in an environment with a relative humidity of 60-70% and a temperature of 30°C for 2 days;

[0031] 4) Germination of brown rice: Soak the selected brown rice in water at 26°C for 17 hours, then take it out and place it in an environment with a relative humidity of 50-70% and a temperatu...

Embodiment 2

[0040] The noodles are made of the following raw materials in parts by weight: 110 parts by weight of flour, 23 parts by weight of quinoa slurry, and 26 parts by weight of brown rice slurry. The process steps are the same as in Example 1.

[0041] The product that embodiment one, two make and the traditional product of control group are carried out component analysis, and result is as follows:

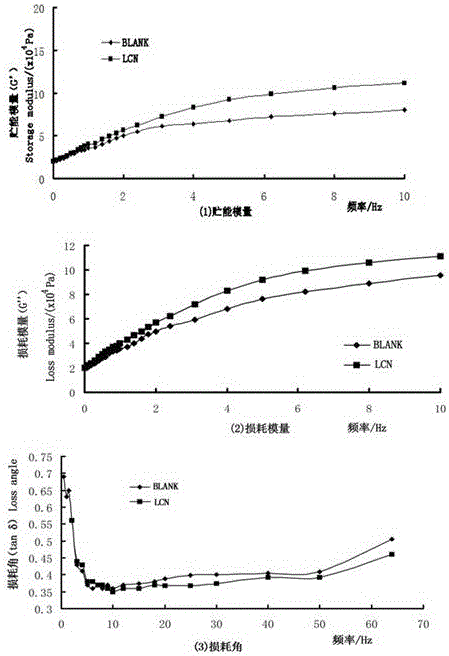

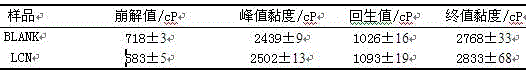

[0042] The protein content of the control group was 10.8%, while the protein content of the treatment group was as high as 13.05%, which improved the nutritional value of noodles. After grinding and crushing, prolamins and gluten are released in the slurry. As a monomer protein, gliadin has a small molecular weight and is mostly composed of non-polar amino acids. It has high fluidity and gives gluten viscosity. Gluten is also an important part of gluten. It is a network polymer connected by intermolecular disulfide bonds, which can endow gluten with resistance to extensibility and ela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com