Method for preparing fermented beverage by utilizing vinasse

A technology for fermented beverages and distiller's grains, applied in the field of food and beverage processing, can solve the problems of inability to effectively form flavored beverage products, cumbersome production processes, and increased costs, and achieve the effects of preventing inhibition, simplifying process steps, and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

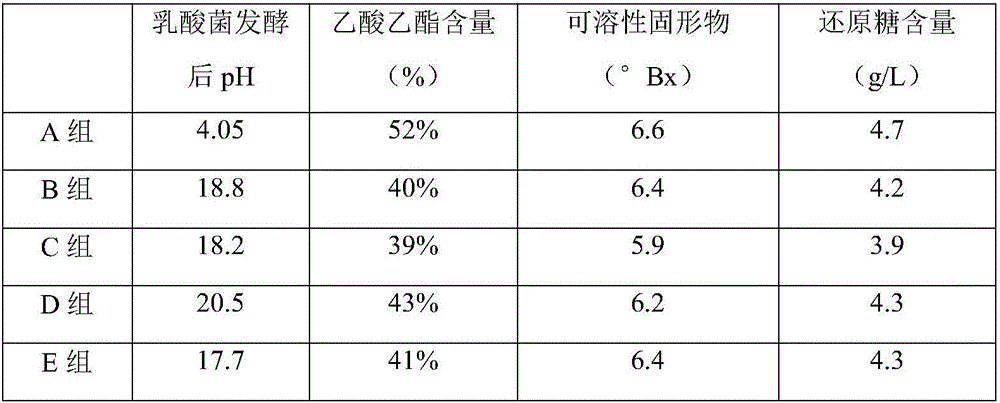

Examples

Embodiment 1

[0025] Produce yellow distiller's grains fermented beverage by following method:

[0026] (1) Mixing and gelatinization of raw materials: mix rice distiller's grains and oats at a mass ratio of 2:1, and directly add rice milk water, a by-product in the rice wine production process, at a mass ratio of 1:6, and boil to paste 50min;

[0027] (2) Liquefaction and beating: Add 0.2% α-amylase (enzyme activity is 4000U / g) in the feed liquid after step (1) gelatinization relative to the total mass of rice distiller's grains and oats for liquefaction, liquefaction The temperature is 65°C, the liquefaction time is 60 minutes, and then beating, the beating time is 6 minutes, and the beating temperature is 50°C;

[0028] (3) Yeast fermentation: In the slurry prepared in the previous step, the activated Saccharomyces cerevisiae was inoculated to a final concentration of 2×10 8 CFU / ml, fermented at 28°C for 5 hours; then centrifuged and treated in boiling water for 20 minutes;

[0029] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com