Method used for measuring cement mortar rheological parameters

A technology of cement mortar and rheological parameters, which is applied in the field of testing the plastic viscosity and yield stress of cement mortar, can solve the problems of complex data processing, unsuitability for measuring rheological parameters of mortar, and complicated testing process, and achieve good repeatability, It is conducive to popularization and use, and the effect of simplifying the data processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

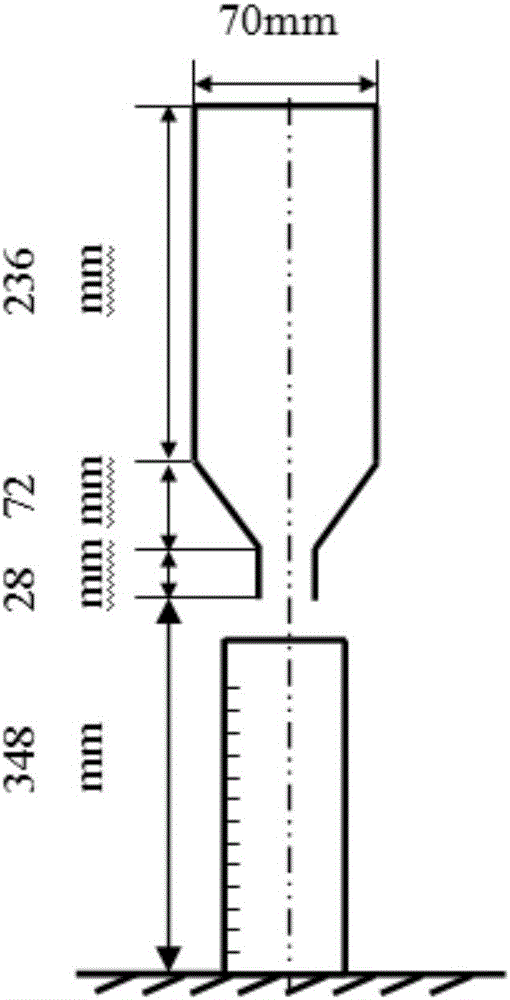

[0036] Such as figure 1 As shown, the charging device selected in this embodiment is that the inner diameter of the cylinder part is 70mm, and the height is 236mm; The diameter is 80mm, and the height from the inner bottom of the receiving measuring cylinder to the outlet of the funnel is 348mm.

[0037] The mortar mix ratio used is: China Resources 42.5R cement 328kg / m 3 , ISO standard sand 1336kg / m 3 , Class II fly ash 164kg / m 3 grams, finely ground slag powder (S95) 109kg / m 3 , Polycarboxylate superplasticizer 5.8kg / m 3 , water 282kg / m 3 . The measured density of cement mortar is 2226kg / m 3 .

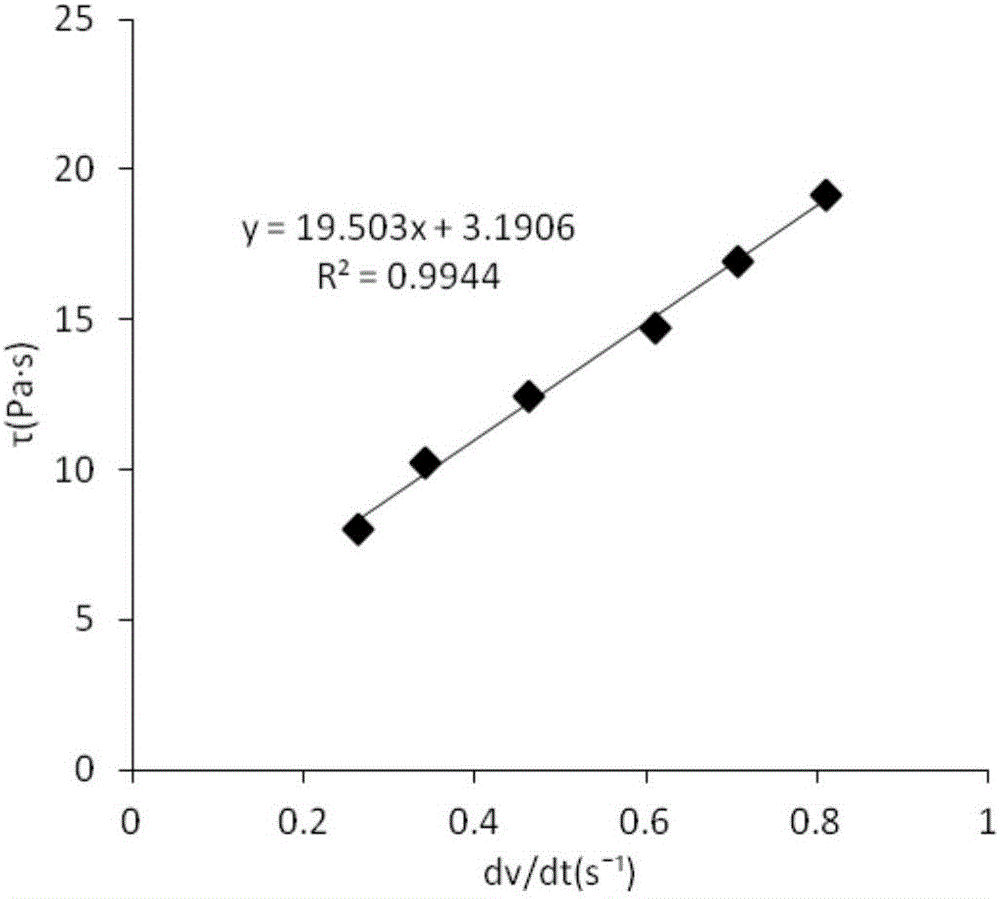

[0038] 1) The test data according to DV playback and calculation are shown in Table 1, figure 1 shown.

[0039] Among them, shear stress = measured density of mortar × volume of upper mortar

[0040]Shear rate = falling distance of the i-th 100ml mortar / falling time of the i-th 100ml mortar = [348-23(i-1)] / Ti

[0041] i refers to the i-th 100mL mortar, T i Refers to the ...

Embodiment 2

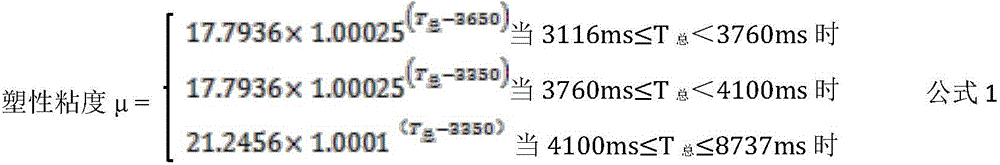

[0054] Such as figure 1 As shown, the charging cylinder is vertically fixed on the central axis of the bracket, the receiving measuring cylinder is placed directly below the charging cylinder, the axes of the charging cylinder and the receiving measuring cylinder coincide, and the stopwatch is placed on the outer circumference of the receiving measuring cylinder; The upper part of the material cylinder is cylindrical, and the lower part is funnel-shaped; the height from the inner bottom of the receiving measuring cylinder to the outlet of the funnel is 348mm; first block the outlet of the funnel, mix 1000mL of mortar and put it into the upper charging cylinder; then loosen Open the outlet of the funnel and let the mortar drop freely into the lower receiving measuring cylinder; use a stopwatch to record the total time T of 800ml mortar falling 总 .

[0055] Specifically, the charging device selected in this embodiment is that the inner diameter of the cylinder part is 70mm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com