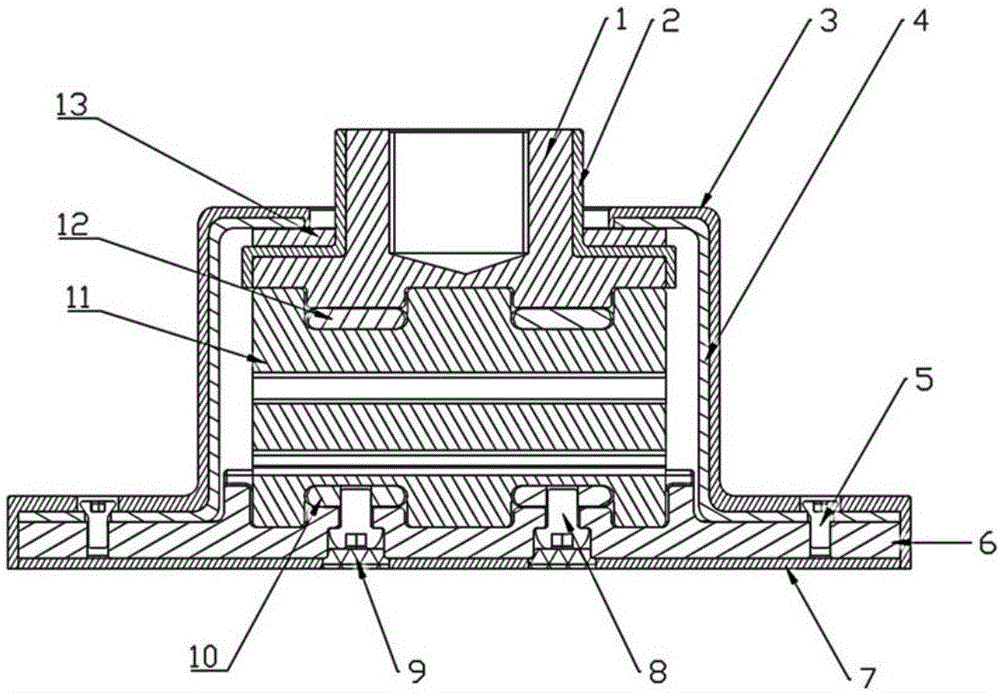

Metamaterial vibration isolator

A metamaterial and vibration isolator technology, applied in the field of vibration reduction and noise reduction, can solve the problems of structural complexity, difficult to achieve extraordinary physical properties, and high precision requirements, and achieve the effect of shortening the development cycle and broadening the selection range of substrates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

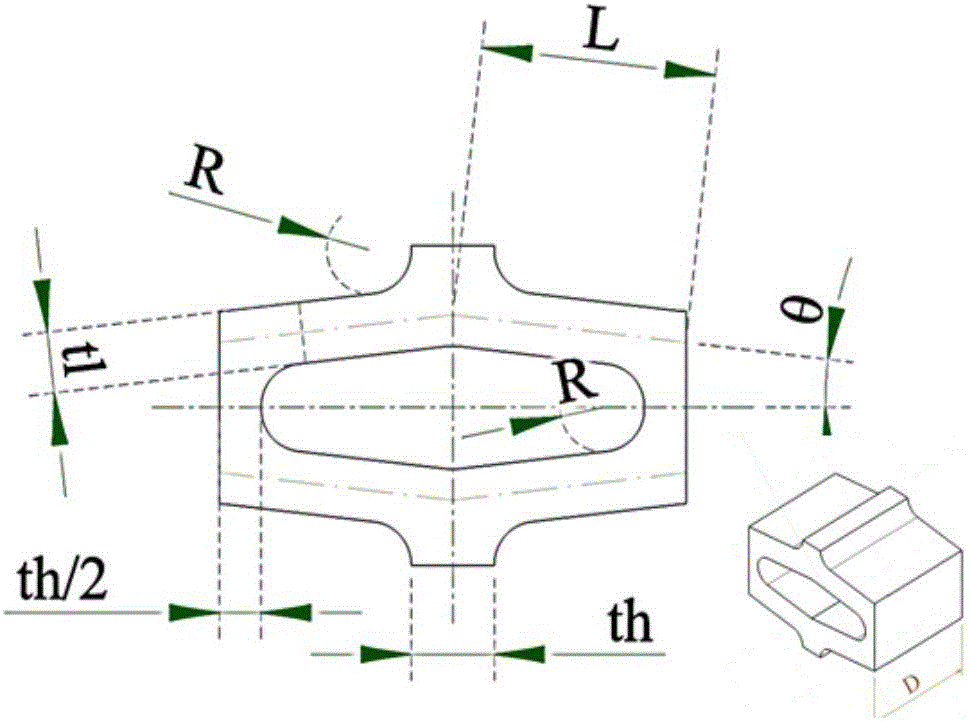

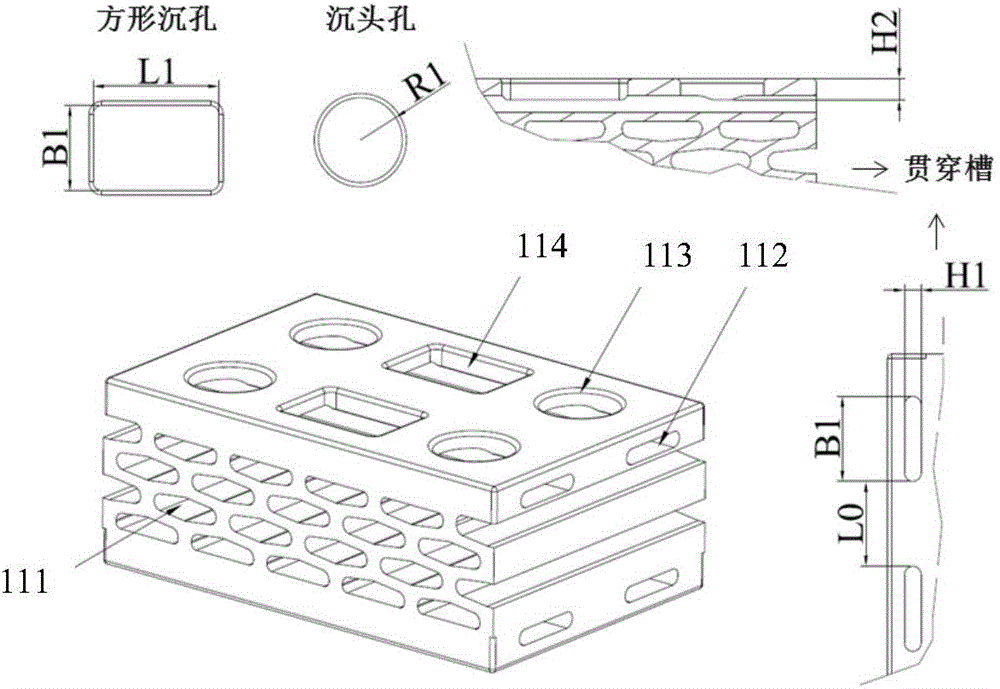

[0042] In Example 2, the metamaterial vibration isolation component 11 is selected as a certain rubber material, the compression modulus of the base material is 110MPa, the design target of the vibration isolator is a rated load of 200Kg, and a static stiffness of 1000N / mm. The structural parameters of the metamaterial unit cell are calculated by the metamaterial design method as follows: the length L of the hypotenuse is 11.66 mm, the angle θ between the hypotenuse and the horizontal direction is 6.5°, and the wall thickness of the hypotenuse is tl The value of th is 2.92mm, the wall thickness th of the vertical side is 4.12mm, the radius R of the inscribed circle in the horizontal direction of the two sets of hypotenuses of the unit cell is 2.1mm: the value range of the penetration depth D of the inner contour of the unit cell is 80mm. The upper and lower assembly ends of the metamaterial vibration-isolation component 11 are provided with two square through-slots 112 perpend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com