Sectional steel horizontal enclosure structure and construction method of subway entrance and exit in rocky strata

A technology of enclosure structure and construction method, which is applied in basic structure engineering, excavation, construction, etc., can solve the problems of large area occupied by construction machinery, difficult realization of station entrances and exits, slow construction speed, etc. The effect of small volume and high noise of machine construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

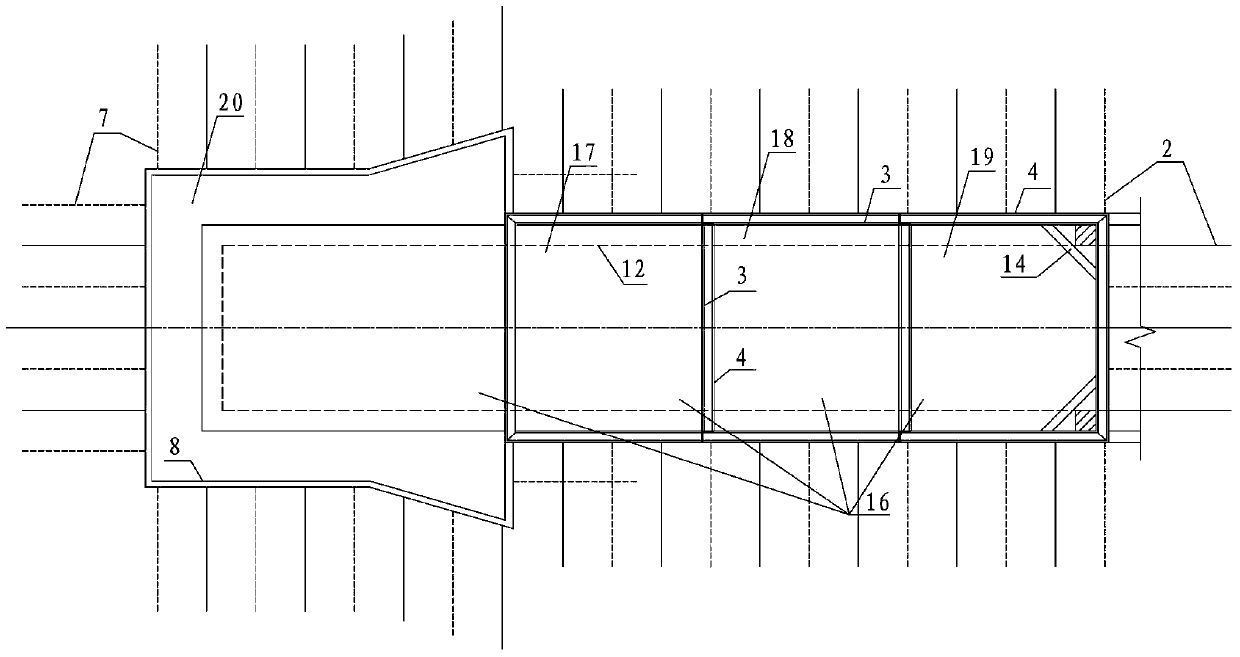

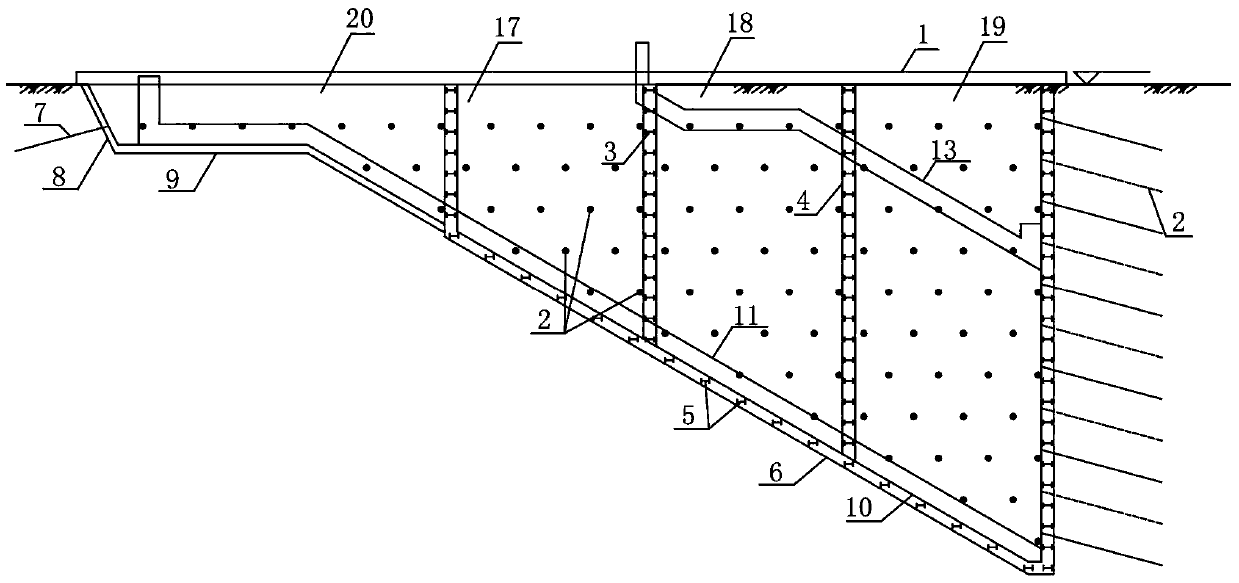

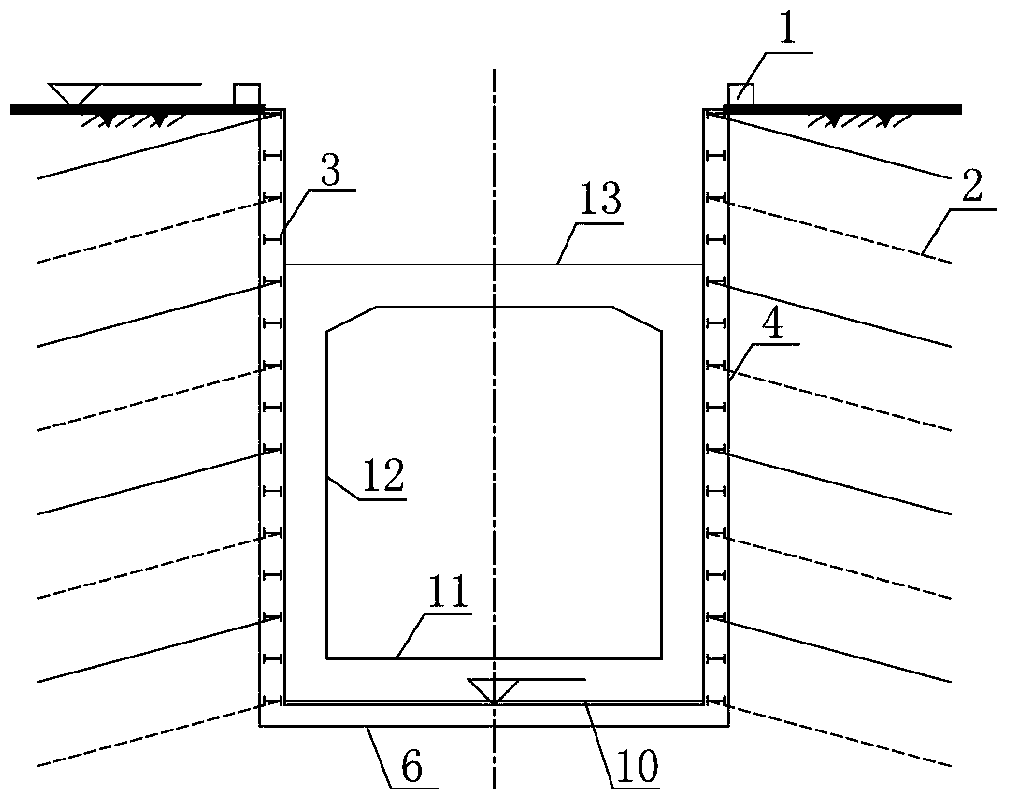

Embodiment 1

[0043] A segmented sectioned steel horizontal enclosure structure for subway entrances and exits in rocky strata, including a concrete roof protection ring 1, side wall section steel 3, side wall anchors 2, side wall hanging net sprayed concrete 4, pit bottom section steel 5, and pit bottom hanging net spraying Concrete 6, waterproof layer 10, bottom plate 11, side wall 12, roof plate 13, foundation pit 16, side wall section steel 3 is fixed on the excavation side of foundation pit 16 through side wall anchors 2, side wall hanging net shotcrete 4 is covered on the side The wall profile steel 3 is combined to form a whole, the pit bottom profile steel 5 is set at the bottom of the bottom foundation pit 16 of the side wall profile steel 3, the bottom hanging net shotcrete 6 is covered on the pit bottom profile steel 5, and the bottom plate 11 is set on the pit bottom hanging net In the shotcrete 6, both sides of the upper end of the bottom plate 11 are connected to the lower end ...

Embodiment 2

[0062] A segmented sectioned steel horizontal enclosure structure for subway entrances and exits in rocky strata, including a concrete roof protection ring 1, side wall section steel 3, side wall anchors 2, side wall hanging net sprayed concrete 4, pit bottom section steel 5, and pit bottom hanging net spraying Concrete 6, waterproof layer 10, bottom plate 11, side wall 12, roof plate 13, foundation pit 16, side wall section steel 3 is fixed on the excavation side of foundation pit 16 through side wall anchors 2, side wall hanging net shotcrete 4 is covered on the side The wall profile steel 3 is combined to form a whole, the pit bottom profile steel 5 is set at the bottom of the bottom foundation pit 16 of the side wall profile steel 3, the bottom hanging net shotcrete 6 is covered on the pit bottom profile steel 5, and the bottom plate 11 is set on the pit bottom hanging net In the shotcrete 6, both sides of the upper end of the bottom plate 11 are connected to the lower end ...

Embodiment 3

[0081]A segmented sectioned steel horizontal enclosure structure for subway entrances and exits in rocky strata, including a concrete roof protection ring 1, side wall section steel 3, side wall anchors 2, side wall hanging net sprayed concrete 4, pit bottom section steel 5, and pit bottom hanging net spraying Concrete 6, waterproof layer 10, bottom plate 11, side wall 12, roof plate 13, foundation pit 16, side wall section steel 3 is fixed on the excavation side of foundation pit 16 through side wall anchors 2, side wall hanging net shotcrete 4 is covered on the side The wall profile steel 3 is combined to form a whole, the pit bottom profile steel 5 is set at the bottom of the bottom foundation pit 16 of the side wall profile steel 3, the bottom hanging net shotcrete 6 is covered on the pit bottom profile steel 5, and the bottom plate 11 is set on the pit bottom hanging net In the shotcrete 6, both sides of the upper end of the bottom plate 11 are connected to the lower end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com