A method of preparing large-area high-quality completely single-layered tungsten disulfide

A tungsten disulfide, large-area technology, applied in chemical instruments and methods, coatings, single crystal growth, etc., can solve the problems of poor controllability of the number and size of single-layer tungsten disulfide layers, poor electrical performance, and high cost , to achieve low-cost continuous mass production, low transfer costs, and easy scale-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

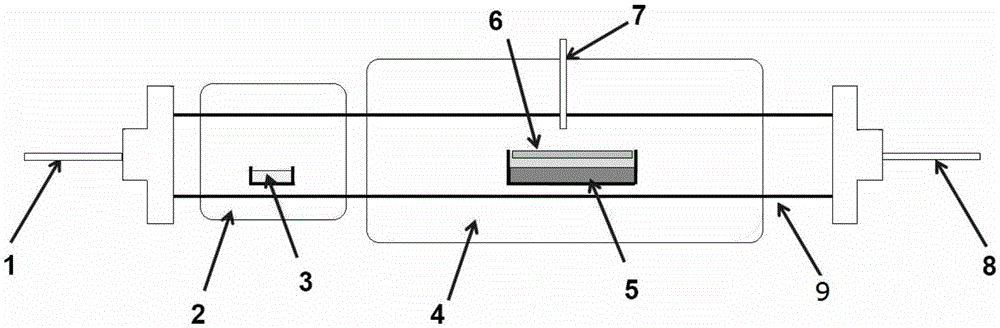

[0037] Such as figure 1 As shown, the present invention adopts the horizontal reaction furnace 4 to grow single-layer tungsten disulfide, and the quartz tube 9 is used as the reactor. The quartz boat of the tungsten oxide powder 5 is placed in the high temperature zone of the horizontal reaction furnace 4, the gold substrate 6 is placed 1 to 10 mm above the tungsten trioxide powder 5, and does not touch the tungsten trioxide powder 5, and the thermocouple 7 is placed in the high temperature zone of the horizontal reaction furnace. zone, to monitor the reaction temperature in real time; the quartz boat filled with sulfur element 3 (such as: sulfur powder, sulfur sheet or sulfur block) is placed upstream in the quartz tube 9 outside the horizontal reaction furnace 4 furnaces, and is used to place the quartz tube The heater 2 outside 9, the heater 2 controls the temperature and heats the sulfur element 3 separately, to generate sulfur vapor. First, the polycrystalline gold sheet...

Embodiment 2

[0040] Such as figure 1 As shown, the present invention adopts the horizontal reaction furnace 4 to grow single-layer tungsten disulfide, and the quartz tube 9 is used as the reactor. The quartz boat of the tungsten oxide powder 5 is placed in the high temperature zone of the horizontal reaction furnace 4, the gold substrate 6 is placed 1 to 10 mm above the tungsten trioxide powder 5, and does not touch the tungsten trioxide powder 5, and the thermocouple 7 is placed in the high temperature zone of the horizontal reaction furnace. zone, to monitor the reaction temperature in real time; the quartz boat filled with sulfur element 3 (such as: sulfur powder, sulfur sheet or sulfur block) is placed upstream in the quartz tube 9 outside the horizontal reaction furnace 4 furnaces, and is used to place the quartz tube The heater 2 outside 9, the heater 2 controls the temperature and heats the sulfur element 3 separately, to generate sulfur vapor. First, the polycrystalline gold sheet...

Embodiment 3

[0044] Such as figure 1 As shown, the present invention adopts the horizontal reaction furnace 4 to grow single-layer tungsten disulfide, and the quartz tube 9 is used as the reactor. The quartz boat of the tungsten oxide powder 5 is placed in the high temperature zone of the horizontal reaction furnace 4, the gold substrate 6 is placed 1 to 10 mm above the tungsten trioxide powder 5, and does not touch the tungsten trioxide powder 5, and the thermocouple 7 is placed in the high temperature zone of the horizontal reaction furnace. zone, to monitor the reaction temperature in real time; the quartz boat filled with sulfur element 3 (such as: sulfur powder, sulfur sheet or sulfur block) is placed upstream in the quartz tube 9 outside the horizontal reaction furnace 4 furnaces, and is used to place the quartz tube The heater 2 outside 9, the heater 2 controls the temperature and heats the sulfur element 3 separately, to generate sulfur vapor. First, the polycrystalline gold sheet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| carrier mobility | aaaaa | aaaaa |

| carrier mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com