An ultra-thin asphalt film for engineering interface treatment and its application method

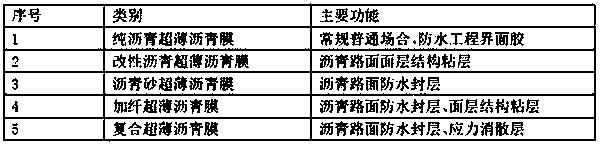

A technology of interface treatment and bituminous membrane, applied in the direction of bituminous material binder, film/sheet without carrier, film/sheet-like binder, etc. and other problems, to achieve the effect of easy portability, significant energy-saving benefits, and elimination of the uniformity of spreading defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Pothole disease is the most common disease on asphalt pavement, and it is also the maintenance object with the largest number of pavement minor repair and maintenance operations, and it is also the most difficult type of disease to deal with; this is due to the small scale of pothole repair and low degree of mechanization; on the other hand It is because the construction time is limited and the interface is difficult to handle in place; therefore, the quality of pothole repair is often not guaranteed, and the probability of secondary damage in situ after repair is very high.

[0032]The detailed treatment of the boundary of the pothole repair process is the most easily overlooked process step, and it is also the most difficult part to achieve the expected effect. It is affected by subjective and objective factors such as the quality of emulsified asphalt, the performance of hand-held sprayers, and the degree of attention of personnel. There is no simple and reliable boun...

Embodiment 2

[0038] In the typical semi-rigid base asphalt pavement structure in China, a sealing layer needs to be set between the semi-rigid base and the asphalt concrete surface to prevent the road surface from seeping into the dense cement-stabilized gravel layer, thereby reducing the occurrence of pumping and subsidence on the pavement and other serious structural damage.

[0039] At present, the construction of asphalt pavement seal is mainly realized by on-site processes such as slurry seal and hot asphalt surface treatment. Due to the influence of current technology and material properties, neither of the two processes can achieve satisfactory results.

[0040] The ultra-thin bituminous film of the present invention is used as the sealing layer of the pavement engineering, and the specific use method is: spread a layer of 0.6mm ultra-thin asphalt film on the cement-stabilized gravel layer, and then spread a layer of 160 mm on the ultra-thin asphalt film. ℃ of asphalt mixture, that ...

Embodiment 3

[0044] Waterproof membrane is a kind of sheet-like impermeable material made of asphalt and tire core. The thickness is generally about 3mm. Its waterproof effect and durability mainly depend on the quality of the membrane itself and the bonding status of the membrane and the building. . At present, the construction of waterproof membrane mainly adopts flame spraying device to grill the membrane itself, and bond it to the top surface of the building when the asphalt on the surface melts. As mentioned above, the heating uniformity of this kind of process is not suitable to be controlled, and two workers are required to cooperate. operation, and because the thickness of the coil itself is large, the required heating time is long and the heating energy consumed is high.

[0045] Use the pure asphalt ultra-thin asphalt film of the present invention as the waterproof membrane interface adhesive (made of high-grade asphalt with a smaller heat capacity, usually with a thickness of 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com