Method for hydroformylation of vinyl acetate

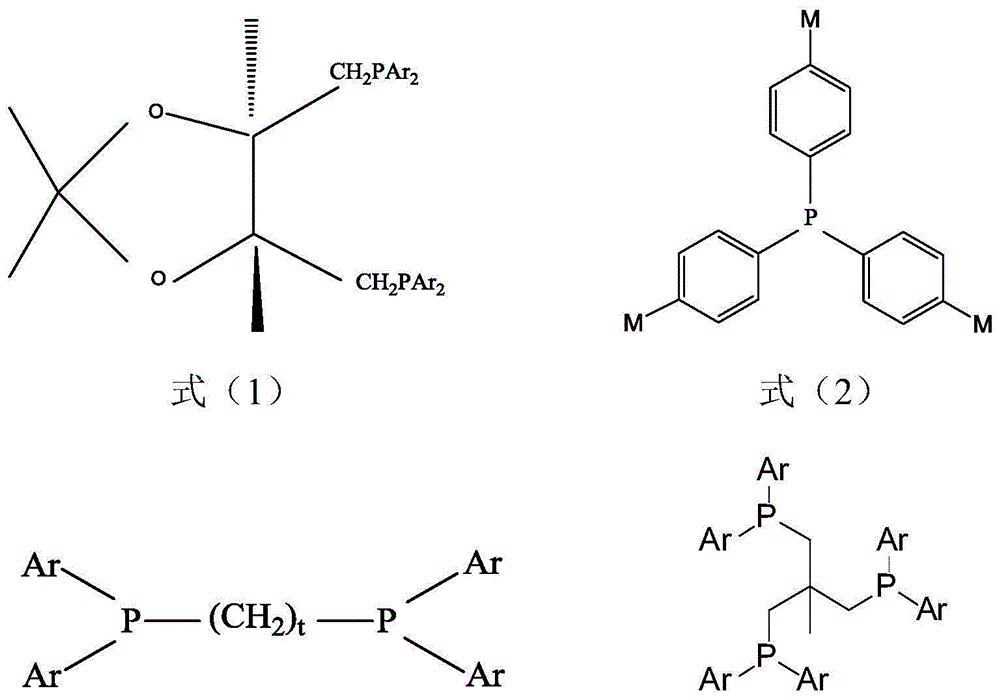

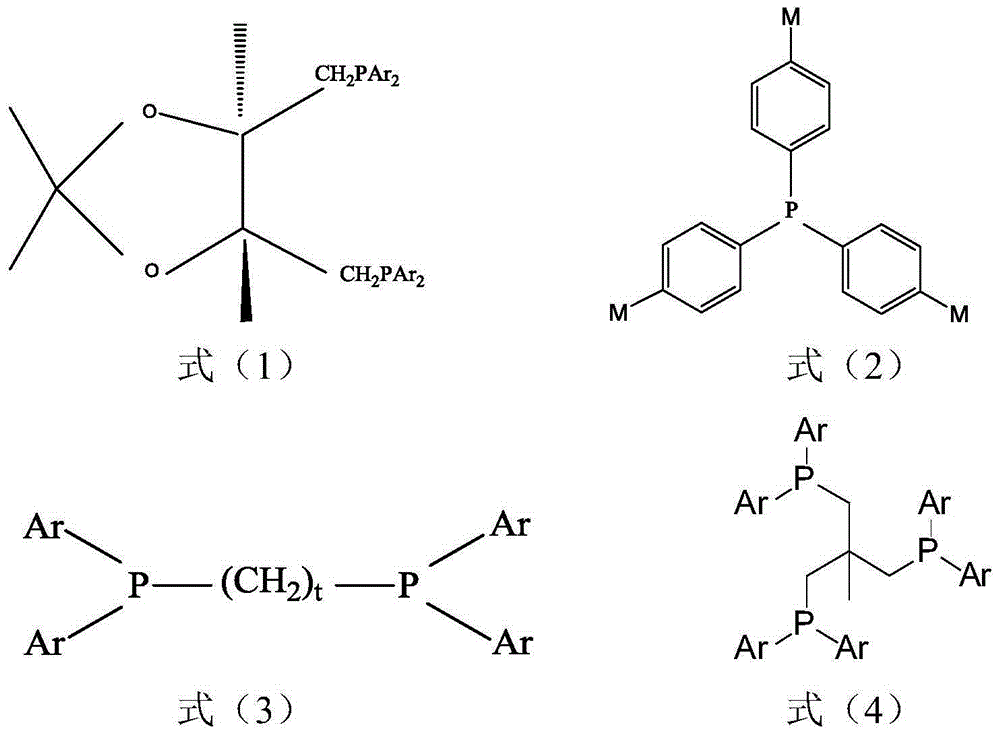

A technology of vinyl acetate hydroformyl and vinyl acetate, which is applied in the field of vinyl acetate hydroformylation, can solve the problems of poor 3-acetoxypropionaldehyde selectivity and harsh reaction conditions, achieves high conversion rate, improves selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0037] According to a preferred embodiment of the present invention, the temperature at which the vinyl acetate is contacted with carbon monoxide and hydrogen is 20-200°C, more preferably 80-120°C.

[0038] According to a preferred embodiment of the present invention, the pressure at which the vinyl acetate is contacted with carbon monoxide and hydrogen is 0.5-10 MPa, more preferably 3-4 MPa. In the present invention, the pressure refers to gauge pressure.

[0039] According to the present invention, the volume ratio of the solvent to vinyl acetate is preferably (0.01-10):1, more preferably (0.01-8):1. Adopting this preferred ratio can further improve the selectivity of 3-acetoxypropanal at lower reaction temperature and reaction pressure.

[0040] According to the present invention, the solvent refers to a solvent that is inert to the hydroformylation reaction but can effectively dissolve raw materials, reaction products and catalysts.

[0041] According to the present inve...

Embodiment 1

[0053] In a 100ml autoclave, add 6ml vinyl acetate (64.88mmol) as the raw material for hydroformylation, 44ml cyclohexane as solvent, 12.2mg acetylacetonate triphenylphosphinecarbonyl rhodium (0.02mmol) and 26.8mg ( +)-Isopropene-2,3-dihydroxy-1,4-bisdiphenylphosphinobutane (0.05 mmol) was used as catalyst, and the reaction vessel was sealed. Replaced with nitrogen three times, with synthesis gas (CO:H 2 The volume ratio is 1:1) and replaced three times, and the pressure is increased to 4.0MPa with synthesis gas, and the temperature is raised to the reaction temperature of 100°C to start the hydroformylation reaction. The synthesis gas consumed by the reaction is indicated by the pressure change of the gas storage tank until the gas is no longer consumed as the end of the reaction. The reaction kettle was lowered to room temperature, unreacted gas was discharged, and then replaced by nitrogen for 3 times, the reaction kettle was opened, the reaction product was analyzed by ga...

Embodiment 2

[0059] According to the method of Example 1, the difference is that 45ml of methyl tert-butyl ether is used as a solvent, and the catalyst added is 24.4mg of triphenylphosphinecarbonyl rhodium acetylacetonate (0.04mmol) and 35.2mg of (+)-isopropylene- 2,3-dihydroxy-1,4 bis(2-naphthyl)phosphinobutane (0.05 mmol), the reaction pressure is 3.5 MPa, and the temperature is 80°C. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com