Method for Determining Mixing Ratio of Steel Fiber Recycled Coarse Aggregate Concrete

A technology for regenerating coarse aggregates and determining methods, applied in the field of concrete preparation, can solve the problems of lack of suitable design methods for the selection of steel fiber dosage, difficulty in ensuring stable material properties, and poor comparability of experimental data, etc. The work performance, the calculation formula is simple and reasonable, and the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Selected recycled aggregate replacement rate r g =0, the steel fiber selects the milling type (MF). The method for determining the mixing ratio of steel fiber recycled coarse aggregate concrete comprises the following steps:

[0041] (1) Determination of water-binder ratio:

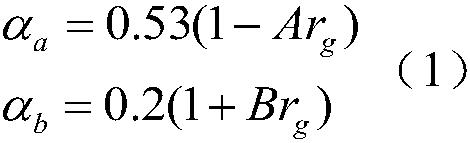

[0042] alpha a =0.53(1-0.1×r g ),α b =0.2(1+0.2×r g ), alpha b = 0.2;

[0043] f ce =45MPa, it can be seen from the above calculation that f cu,0 =49.87MPa, into the formula f cu,0 = α a f ce (C / W-α b ), it can be obtained that W / C=0.43.

[0044] (2) Determination of the amount of steel fiber:

[0045] The target bending and tensile strength of concrete f tm =10MPa; target compressive strength of concrete cube f cu =40MPa

[0046] According to CEB-FIP (1990), (f c ' is the standard cylinder compressive strength of concrete), according to f tm,0 =5.03MPa;

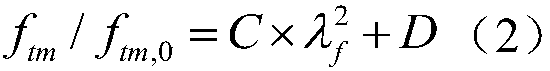

[0047] Due to the calculated bending and tensile strength of the plain concrete matrix (f tm,0 =5.03MPa) is less than...

Embodiment 2

[0067] Selected recycled aggregate replacement rate r g=50%, the steel fiber selects the milling type MF, the method for determining the mixing ratio of the steel fiber recycled coarse aggregate concrete includes the following steps:

[0068] (1) Determination of water-binder ratio:

[0069] alpha a =0.53(1-0.1×r g ),α b =0.2(1+0.2×r g ), alpha b =0.22;

[0070] will f ce =45MPa, f cu,0 =49.87MPa into the formula f cu,0 = α a f ce (C / W-α b ), it can be obtained that W / C=0.41. (2) Determination of the amount of steel fiber:

[0071] The target bending and tensile strength of concrete f tm =10MPa; concrete cube target compressive strength, f cu =40MPa;

[0072] Steel fiber type and aspect ratio are all identical with embodiment 1, and its calculation process is identical with embodiment 1, and the result can get: λ f =0.63, V f = 1.84%.

[0073] (3) Determination of unilateral water consumption:

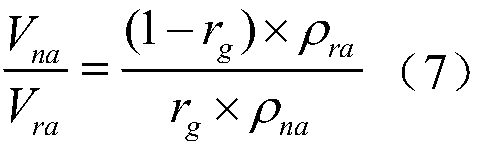

[0074] Set slump T=50mm, the steel fiber content characteris...

Embodiment 3

[0093] Selected recycled aggregate replacement rate r g =100%, the steel fiber selects the milling type MF, and the method for determining the mix ratio of steel fiber recycled coarse aggregate concrete includes the following steps:

[0094] (1) Determination of water-binder ratio:

[0095] alpha a =0.53(1-0.1×r g ),α b =0.2(1+0.2×r g ), alpha b =0.24;

[0096] will f cu,0 =49.87MPa, f ce =45MPa into the formula f cu,0 = α a f ce (C / W-α b ), it can be obtained that W / C=0.39. (2) Determination of the amount of single steel fiber:

[0097] The target bending and tensile strength of concrete f tm = 10MPa, the target compressive strength of concrete cube f cu =40MPa;

[0098] Steel fiber type and aspect ratio are all identical with embodiment 1, and its calculation process is identical with embodiment 1, λ f =0.63, V f = 1.84%. (3) Determination of unilateral water consumption:

[0099] Set slump T=50mm, the steel fiber content characteristic parameter λ that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com