Preparation method of titanium dioxide conductive powder

A technology of titanium dioxide and conductive powder, applied in the field of preparation of functional materials, can solve the problems of uncontrollable, large fluctuation, uneven chemical composition, etc., and achieve the effect of reducing consumption and dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

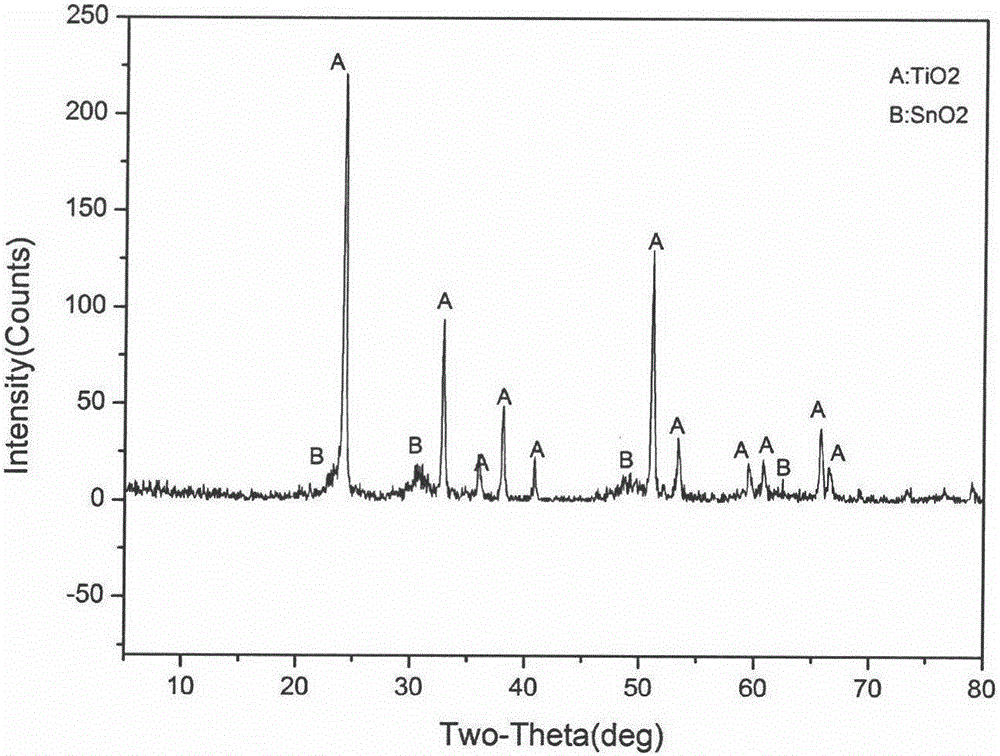

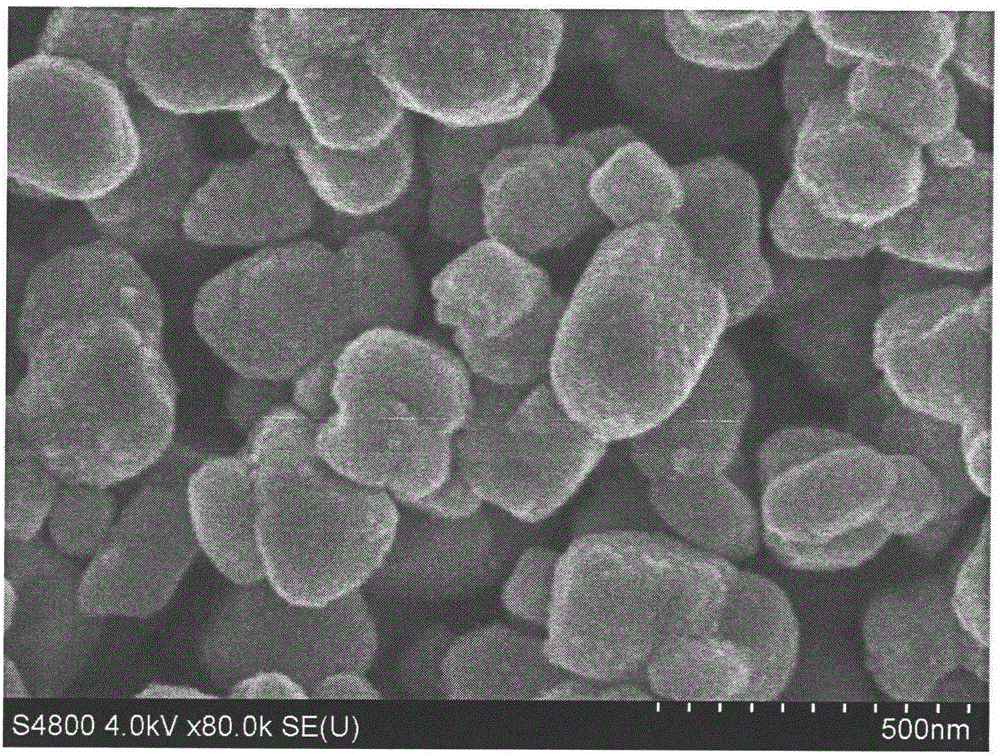

Image

Examples

Embodiment 1

[0018] Embodiment 1: Get 20 grams of rutile titanium dioxide; Add 80 milliliters of deionized water; Add medium bead glass beads accounting for 1 / 3 of the total volume of the material, and the diameter of the ball is 1 cm; Add 9.2 grams of SnCl under stirring 4 .5H 2 O; add 0.59 g of SbCl 3 ; Add 0.28 grams of niobium pentoxide; finally add 2 grams of zinc, stir and react for 120 minutes after adding zinc, adjust the pH value to 2.7 with ammonia water, obtain the wet material of the precursor by suction filtration, and use 5 times the volume of the precursor after removing the filtrate The deionized water was washed twice for use, and the obtained precursor wet material was light gray. Dry the wet precursor at 130°C for 13 hours. Raise the temperature from room temperature to 560°C and roast for 5.5 hours to obtain loose massive titanium dioxide, which is pulverized by a jet mill to obtain titanium dioxide conductive powder. The appearance color of the obtained powder is off...

Embodiment 2

[0019] Embodiment 2: Get 20 grams of rutile titanium dioxide; Add 80 milliliters of deionized water; Add medium bead glass beads accounting for 1 / 3 of the total volume of the material, and the diameter of the ball is 1 cm; Add 11.2 grams of SnCl under stirring 4 .5H 2 O; add 0.41 g of SbCl 3 ; Add 0.4 grams of niobium pentoxide; finally add 2 grams of zinc, after adding zinc, stir and react for 120 minutes, adjust the pH value to 3 with ammonia water, obtain the wet material of the precursor by suction filtration, remove the filtrate, and use 5 times the volume of the precursor The deionized water was washed twice for use, and the obtained precursor wet material was light gray. Dry the wet precursor at 130°C for 13 hours. Raise the temperature from room temperature to 560°C and roast for 5.5 hours to obtain loose massive titanium dioxide, which is pulverized by a jet mill to obtain titanium dioxide conductive powder. The appearance color of the obtained powder is off-white w...

Embodiment 3

[0020]Embodiment 3: Get 20 grams of rutile titanium dioxide; Add 80 milliliters of deionized water; Add medium bead glass beads accounting for 1 / 3 of the total volume of the material, and the diameter of the ball is 1 cm; Add 9.2 grams of SnCl under stirring 4 .5H 2 O; add 0.59 g of SbCl 3 ; Add 0.28 grams of niobium pentoxide; finally add 3 grams of zinc, stir and react for 180 minutes after adding zinc, adjust the pH value to 3.5 with ammonia water, obtain the wet material of the precursor by suction filtration, and use 5 times the volume of the precursor after removing the filtrate The deionized water was washed twice for use, and the obtained precursor wet material was light gray. Dry the wet precursor at 150°C for 10 hours. Raise the temperature from room temperature to 520°C and roast for 5 hours to obtain loose massive titanium dioxide, which is pulverized by a jet mill to obtain titanium dioxide conductive powder. The appearance color of the obtained powder is off-wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com