Rapid forming method capable of compositing fiber and resin-based material

A molding method and resin-based technology, applied in the direction of liquid material additive processing, additive processing, coating devices, etc., can solve the problems of long production cycle, low efficiency, and inability to fully meet customer product needs, and achieve The effect of reducing production costs and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

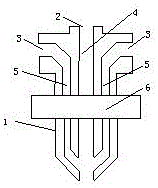

Image

Examples

Embodiment 1

[0014] A molding process of composite materials in this embodiment uses carbon fiber and polylactic acid as raw materials. First, use the 3DMAX software in the computer to design the required three-dimensional finished product model, and then copy the designed model into the 3D printer in STL format. , design the process parameters according to the melting point temperature of the fiber and resin matrix, the process parameters include the temperature to be reached when the nozzle is heated, and the temperature of the 3D printer hotbed; then use the Cura software in the computer to slice the model in STL format Layered processing, and the three-dimensional finished product model is subjected to layered surface processing and stored in the computer, and the layered processing of the three-dimensional finished product model can solve the problem of the three-dimensional finished product model in the computer coordinate system and the printing equipment coordinate system. conversio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com