Sewage treatment sludge active carbon having continuous pore size distribution, and preparation method thereof

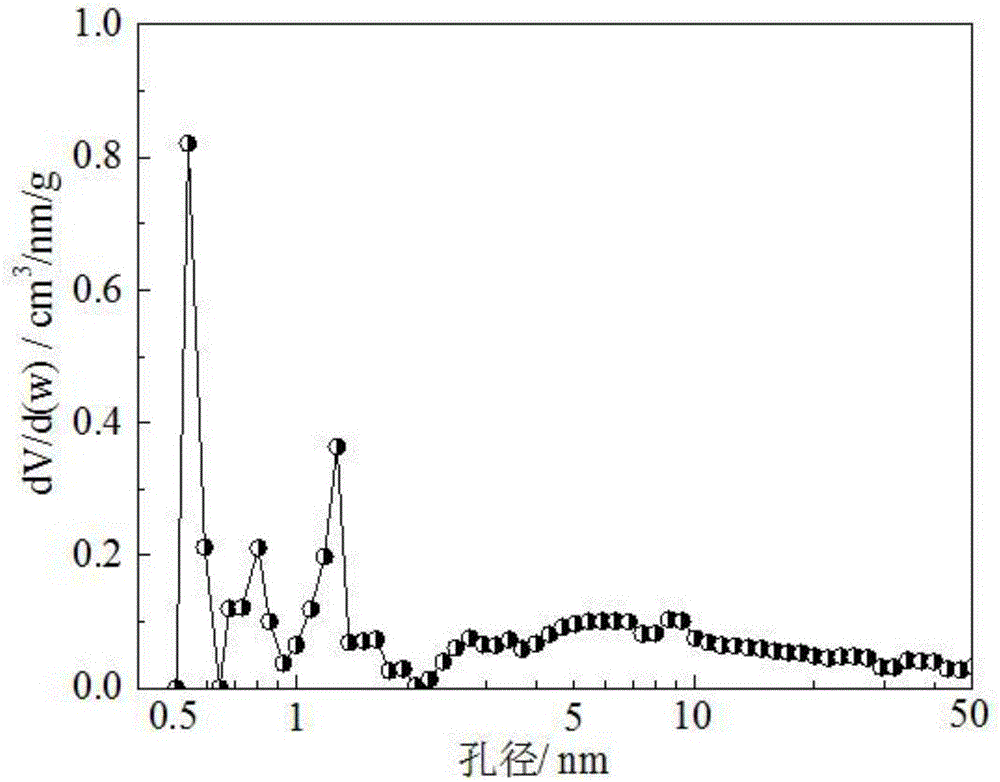

A sludge activated carbon and sewage treatment technology, applied in the field of environmental resource utilization, can solve problems such as difficult to achieve high-efficiency adsorption of heavy metal ions and macromolecular pollutants, and lack of microporous structure, so as to promote pore development, reduce preparation costs, and enhance replacement performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

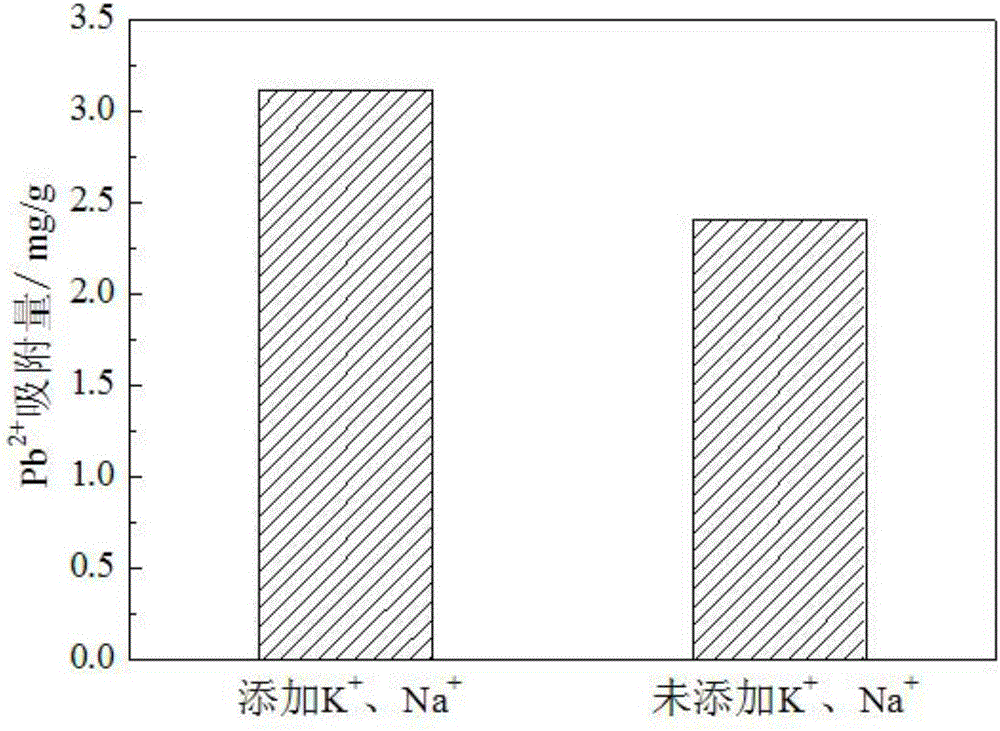

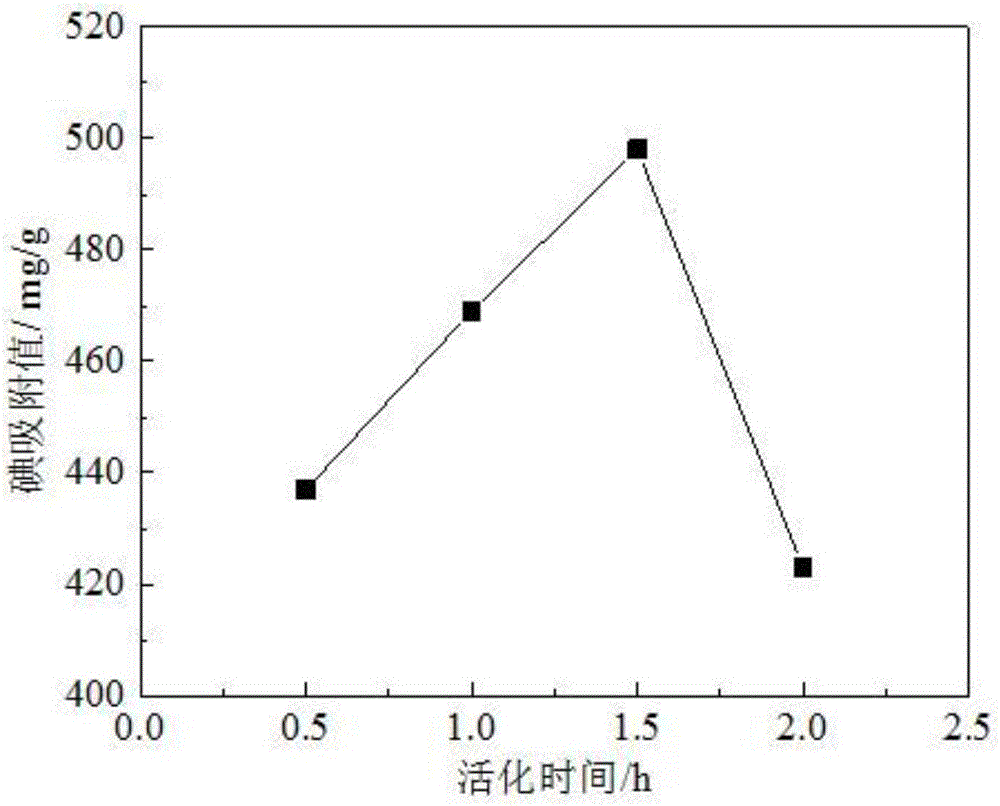

[0035] Immerse the sludge powder into the compound activator solution, the ratio of solid mass to solution volume is 1:2, and immerse at 20 degrees Celsius for 12 hours; the compound activator includes ZnCl 2 , phosphoric acid, K 2 S and NaCl, among which ZnCl 2 Concentration is 2mol / L, phosphoric acid concentration is 3mol / L, K 2 The addition amount of S is 10% of the dry sludge mass, and the NaCl addition amount is 1% of the dry sludge mass. Dry the mixture to a moisture content of 8%, add coal tar, the mass ratio of the mixture to coal tar is 1:0.3; granulate into a cylinder with a diameter of 8 mm and a length of 15 mm. Under the condition of nitrogen flow rate of 350ml / min, 35g of molding raw material was heated from room temperature of 20°C to 550°C at a rate of 10°C / min, and stayed for 1.5h. Then with a heating rate of 15°C / min, the temperature was raised to 800°C, and a mixed gas of water vapor and nitrogen was introduced simultaneously, the flow rate was 350ml / min,...

Embodiment 2

[0037] Immerse the sludge powder into the compound activator solution, the ratio of solid mass to solution volume is 1:2.5, and immerse at 20 degrees Celsius for 8 hours; the compound activator includes ZnCl 2 , phosphoric acid, K 2 S and NaCl, among which ZnCl 2 Concentration is 2.5mol / L, phosphoric acid concentration is 2mol / L, K 2 The addition amount of S is 15% of the dry sludge mass, and the NaCl addition amount is 2% of the dry sludge mass. Dry the mixture to a moisture content of 8%, add coal tar, the mass ratio of the mixture to coal tar is 1:0.35; granulate into a cylinder with a diameter of 8 mm and a length of 15 mm. Under the condition of nitrogen flow rate of 350ml / min, 52.5g of molding raw material was heated from room temperature of 25°C to 650°C at a rate of 15°C / min, and stayed for 1h. Then with a heating rate of 12° C. / min, the temperature is raised to 700° C., and a mixed gas of water vapor and nitrogen is introduced at the same time, the flow rate is 350...

Embodiment 3

[0039] Immerse the sludge powder into the compound activator solution, the ratio of solid mass to solution volume is 1:2, and immerse at 20 degrees Celsius for 12 hours; the compound activator includes ZnCl 2 , phosphoric acid, K 2 S and NaCl, among which ZnCl 2 Concentration is 1mol / L, phosphoric acid concentration is 5mol / L, K 2 The addition amount of S is 8% of the dry sludge mass, and the NaCl addition amount is 0.5% of the dry sludge mass. Dry the mixture to a moisture content of 6%, add coal tar, the mass ratio of the mixture to coal tar is 1:0.2; granulate into a cylinder with a diameter of 8 mm and a length of 15 mm. Under the condition of nitrogen flow rate of 350ml / min, 40g of molding raw material was heated from room temperature of 20°C to 450°C at a rate of 8°C / min, and stayed for 2.5h. Then with a heating rate of 20°C / min, the temperature is raised to 850°C, and simultaneously feed a mixed gas of water vapor and nitrogen, the flow rate is 350ml / min, the water v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com