A separating membrane used for a lithium ion battery, a preparing method thereof and the lithium ion battery

A lithium ion battery and separator technology, applied in the field of lithium ion battery separator and its preparation, can solve the problems of uneven material dispersion, easy defects of pole pieces, long mixing time and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0020] According to the lithium-ion battery separator of the present invention, as long as the side coated with the lithium titanate layer is attached to the negative electrode of the lithium-ion battery, the object of the present invention can be achieved, and the thickness of the lithium titanate layer can be relatively high. Choose from a wide range. According to a preferred embodiment of the present invention, the thickness of the lithium titanate layer is 2-5 μm.

[0021] In addition, according to the separator for a lithium ion battery of the present invention, the average particle size of the lithium titanate particles in the lithium titanate layer may be 100-500 nm, preferably 200-400 nm.

[0022] The present invention has no particular limitation on the coating on the other side of the lithium ion battery separator, which can be various coatings conventionally used, as long as the positive and negative electrodes of the lithium ion battery can be effectively insulated, the...

Embodiment 1-5

[0076] Used to illustrate the separator for lithium ion battery provided by the present invention and its preparation and lithium ion battery

[0077] 1. Diaphragm for lithium ion battery and its preparation

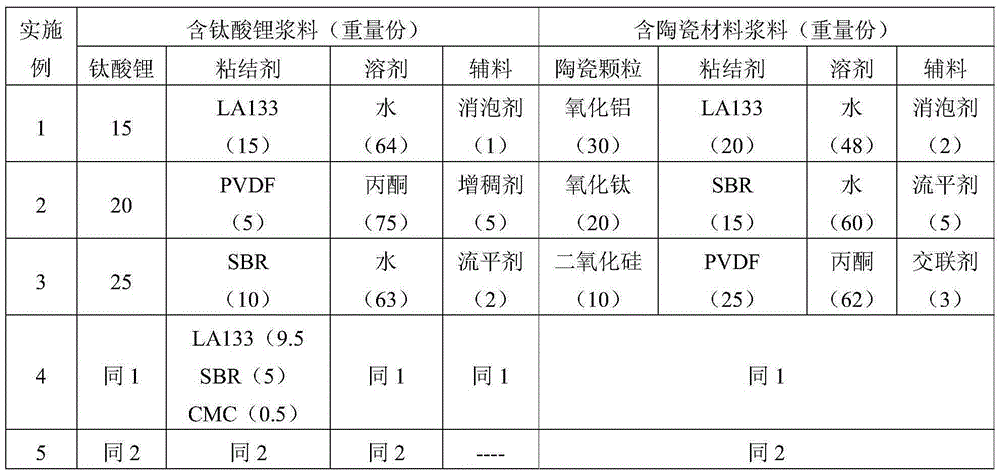

[0078] (1) Preparation of slurry containing lithium titanate

[0079] According to the weight percentage in Table 1, mix the binder, solvent and optional auxiliary materials, stir at 1000 rpm for 60 minutes to make the dispersion uniform, and then add lithium titanate particles with a particle size of 200-400 nm according to the weight in Table 1. Stir at 1200rpm for 120min at no more than 70℃ to make the mixture uniformly dispersed. Then the uniformly dispersed mixture material is vacuum degassed, thereby obtaining slurries ST1-ST5 containing lithium titanate.

[0080] (2) Preparation of slurry containing ceramic materials

[0081] According to the weight percentage in Table 1, mix the binder, solvent and auxiliary materials, stir at 1000 rpm for 60 minutes to make the dispersi...

Embodiment 6

[0099] Used to illustrate the separator for lithium ion battery provided by the present invention and its preparation and lithium ion battery

[0100] The lithium ion battery separator and lithium ion battery were prepared according to the method of Example 4. The difference is that during the preparation of the lithium titanate slurry, the CMC, solvent and auxiliary materials were mixed together, and LA133 was added after uniform dispersion. Then add 15 parts by weight of lithium titanate particles with a particle size, stir at 1000 rpm for 60 minutes to make the dispersion uniform, then add SBR, and stir at 1200 rpm for 120 minutes at no more than 70°C to make the mixture uniformly dispersed. Then the uniformly dispersed mixture material is vacuum degassed, thereby obtaining a slurry ST6 containing lithium titanate.

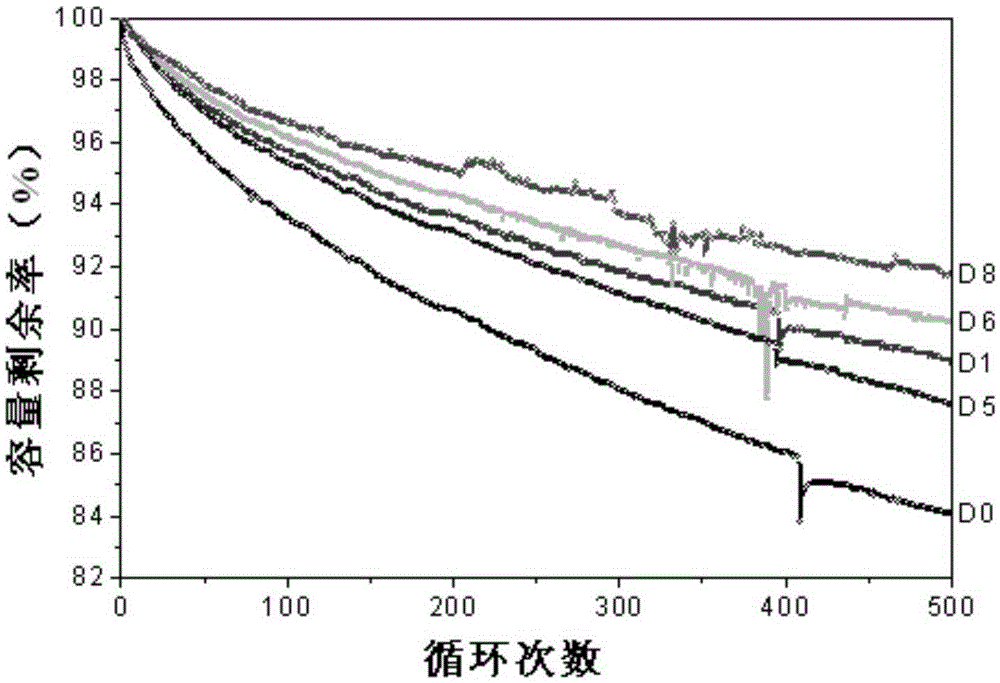

[0101] The instantaneous rate charging performance of the obtained lithium ion battery D6 is shown in Table 2, the low temperature charging performance is shown in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com