Test method for studying rock joint surface morphology evolution in whole shear process

A test method, shear test technology, applied in the direction of applying stable shear force to test the strength of materials, measuring devices, instruments, etc., can solve the problems of overestimation of processing methods, large gaps, etc., and achieve true and repeatable results sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment studies the test method of rock joint surface morphology evolution in the whole process of shearing, and the test method includes the following steps:

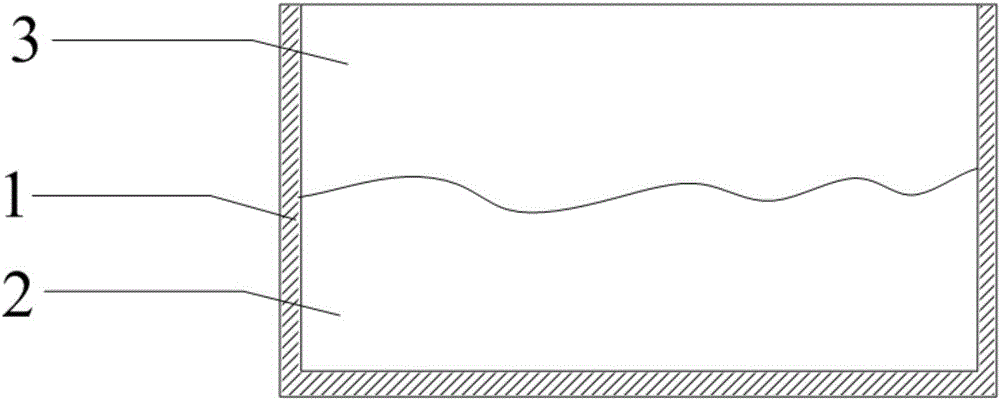

[0042] 1) Copy the natural rock joint surface with fine mold silica gel: select the natural rock joint surface, cut it into a plane size of 100mm×200mm, put it into the steel mold 1, and evenly paint the surface of the natural rock joint 2 and the inner side of the steel mold 1 for demoulding Agent; Weigh the fine mold silica gel and curing agent with a mass ratio of 100:1, stir until fully mixed, put into the container, the colloid accounts for no more than 50% of the volume of the container, and put it into a vacuum cylinder to evacuate to eliminate the silica gel. air bubbles; the vacuumed silica gel layered evenly poured on the surface of the natural rock joint 2, let stand for 24 hours and then demolded to obtain the silica gel joint sample 3, as figure 1 shown;

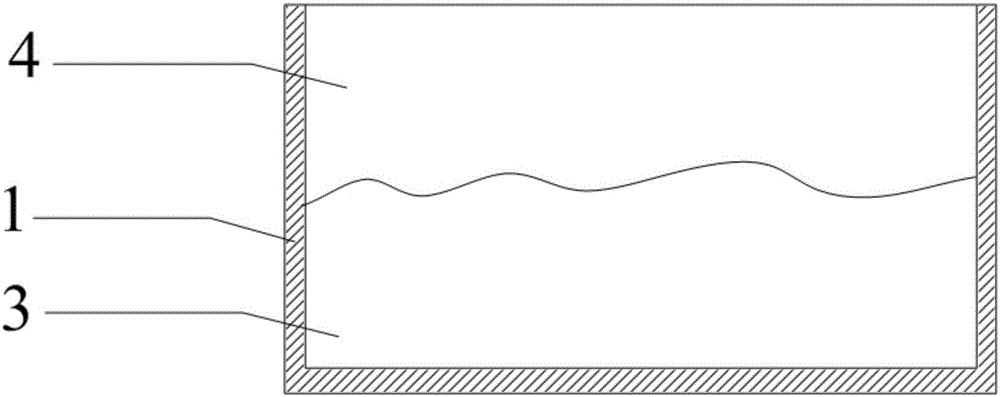

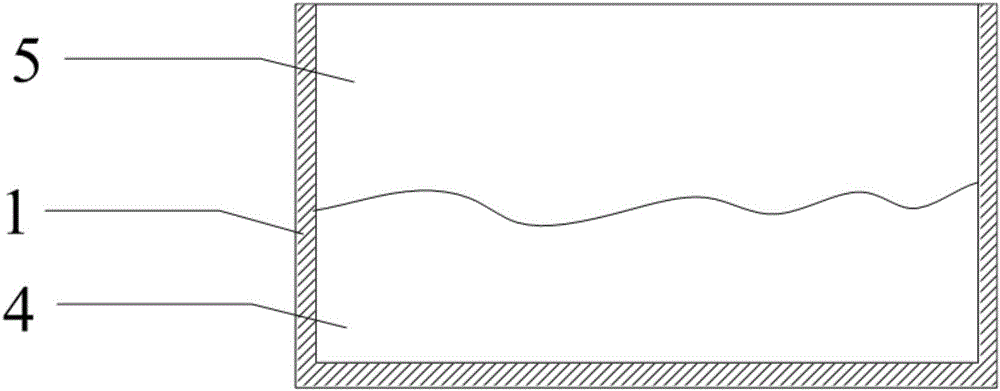

[0043] 2) Pouring the upper part 5...

Embodiment 2

[0050] In this example, the water-cement ratio of the α high-strength gypsum material is 1:3, and the rest are the same as Example 1.

Embodiment 3

[0052] In this example, the water-cement ratio of the α-high-strength gypsum material is 1:5, and the rest are the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com