Sulfur-modified emulsified asphalt and preparation method thereof

A technology of emulsified asphalt and sulfur, which is applied in the direction of building components, building insulation materials, buildings, etc., can solve the problems that the temperature of the mixture should not be too high, the storage time should not be too long, and the human body will be injured, so as to improve the rutting and avoid heating and harmful gas, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

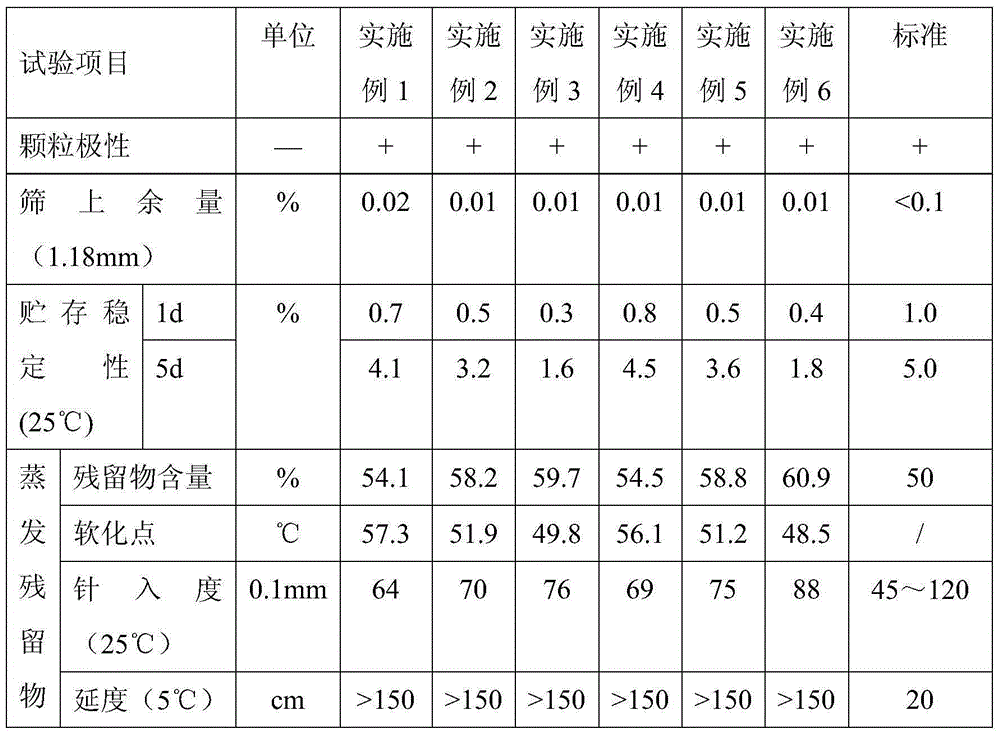

Examples

Embodiment 1

[0027] The sulfur-modified emulsified asphalt of the present invention is composed of the following raw materials in parts by mass: 40 parts of 70# heavy traffic asphalt, 20 parts of 800 mesh sulfur powder, 10 parts of styrene-butadiene latex with a solid content of 40%, and 1 part of nonionic emulsifier op-10 , 0.5 parts of cationic composite emulsifier (0.3 part of trimethylamine lignin, 0.2 part of cationic emulsifier cetyltrimethylammonium chloride), 0.03 part of polyacrylamide, 0.5 part of hydrochloric acid, 50 parts of water.

[0028] The preparation method of sulfur modified emulsified asphalt of the present invention is:

[0029] Add 1 part of nonionic emulsifier to 45 parts of hot water at 55°C to dissolve, add 20 parts of sulfur powder to the aqueous solution of nonionic emulsifier, and prepare a sulfur powder suspension under the action of strong stirring by an emulsifier, and then weigh Take 0.5 part of cationic composite emulsifier (0.3 part of trimethylamine lign...

Embodiment 2

[0031] The sulfur-modified emulsified asphalt of the present invention is composed of the following raw materials in parts by mass: 45 parts of 70# heavy traffic asphalt, 12.5 parts of 600 mesh sulfur powder, 5 parts of styrene-butadiene latex with a solid content of 40%, and 0.7 parts of nonionic emulsifier op-10 , 1 part of cationic composite emulsifier (0.5 part of N-aminoethylamide, 0.5 part of cationic emulsifier cetyltrimethylammonium chloride), 0.05 part of polyacrylamide, 1 part of hydrochloric acid, 40 parts of water.

Embodiment 3

[0033] The sulfur-modified emulsified asphalt of the present invention is composed of the following raw materials in parts by mass: 50 parts of 70# heavy traffic asphalt, 5 parts of 500 mesh sulfur powder, 2 parts of styrene-butadiene latex with a solid content of 40%, and 0.3 parts of nonionic emulsifier op-10 , 3 parts of cationic compound emulsifier (22 parts of 1-aminoethyl-2-heptadecyl imidazoline, 1 part of cationic emulsifier hexadecyltrimethylammonium chloride), 0.1 part of polyacrylamide, hydrochloric acid 3 parts, 35 parts of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com