Easy-to-process metallocene polyethylene composition and its preparation method

A technology for metallocene polyethylene and composition, which is applied in the field of easy-to-process metallocene polyethylene composition and its preparation, can solve problems such as affecting production efficiency and increasing production cost, and achieves improvement of optical properties, processing efficiency and processing performance. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

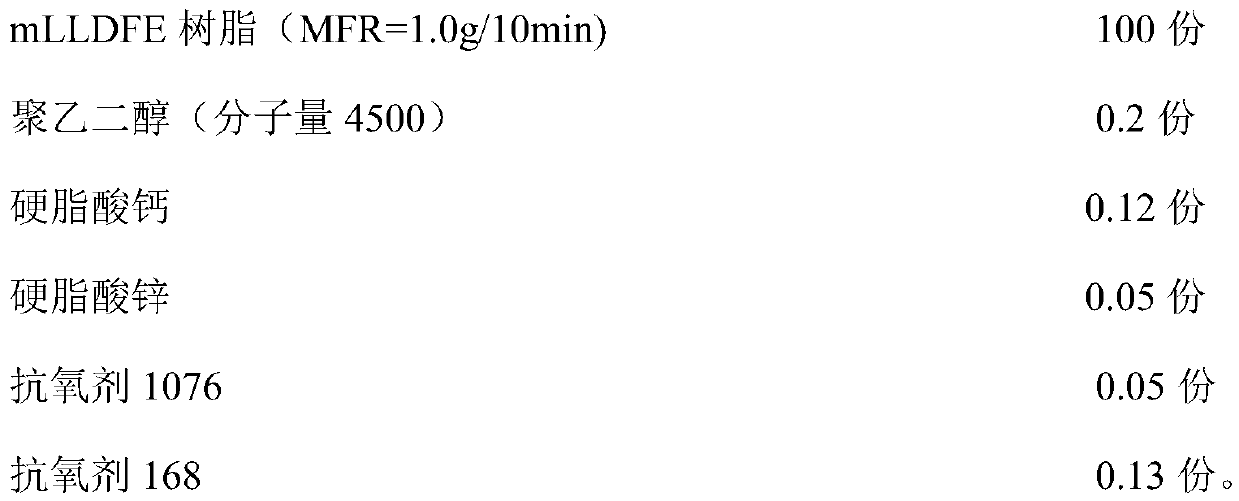

[0036] Raw materials and parts by weight thereof for preparing the easy-to-process metallocene polyethylene composition are:

[0037]

[0038] The preparation steps of the easy-to-process metallocene polyethylene composition: Add polyethylene glycol, calcium stearate, zinc stearate, and antioxidant to the mLLDPE powder resin, mix in a high-speed mixer, and the stirring speed is 1200 rpm , the stirring time is 14min, and the stirring temperature is 40°C; the uniformly mixed material is put into a twin-screw extruder for melting, plasticizing, extruding, and granulating.

[0039] The length-to-diameter ratio of the screw is 34, and there are 6 shear blocks in the screw combination used, including 3 reverse shear blocks; the processing temperature is 190°C, and the vacuum is drawn during the granulation process, and the vacuum degree achieved by the granulation vacuum is -0.3 MPa.

Embodiment 2

[0041] Raw materials and parts by weight thereof for preparing the easy-to-process metallocene polyethylene composition are:

[0042]

[0043]The preparation steps of the easy-to-process metallocene polyethylene composition: Add polyethylene glycol, calcium stearate, zinc stearate, and antioxidant to the mLLDPE powder resin, mix in a high-speed mixer, and the stirring speed is 1700 rpm , the stirring time is 12min, and the stirring temperature is 37°C; the uniformly mixed material is put into a twin-screw extruder for melting, plasticizing, extruding, and granulating.

[0044] The length-to-diameter ratio of the screw is 38, and the screw combination used has 8 shear blocks, including 4 reverse shear blocks; the processing temperature is 210°C, and the vacuum is drawn during the granulation process, and the vacuum degree achieved by the granulation vacuum is -0.2 MPa.

Embodiment 3

[0046] Raw materials and parts by weight thereof for preparing the easy-to-process metallocene polyethylene composition are:

[0047]

[0048] The preparation method of this embodiment is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com