Antistatic anti-electromagnetic radiation composite fabric

A technology for preventing electromagnetic radiation and composite fabrics, applied in protective clothing, clothing, special outerwear, etc., can solve problems such as poor environmental performance, poor softness and comfort of fabrics, and electromagnetic radiation protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

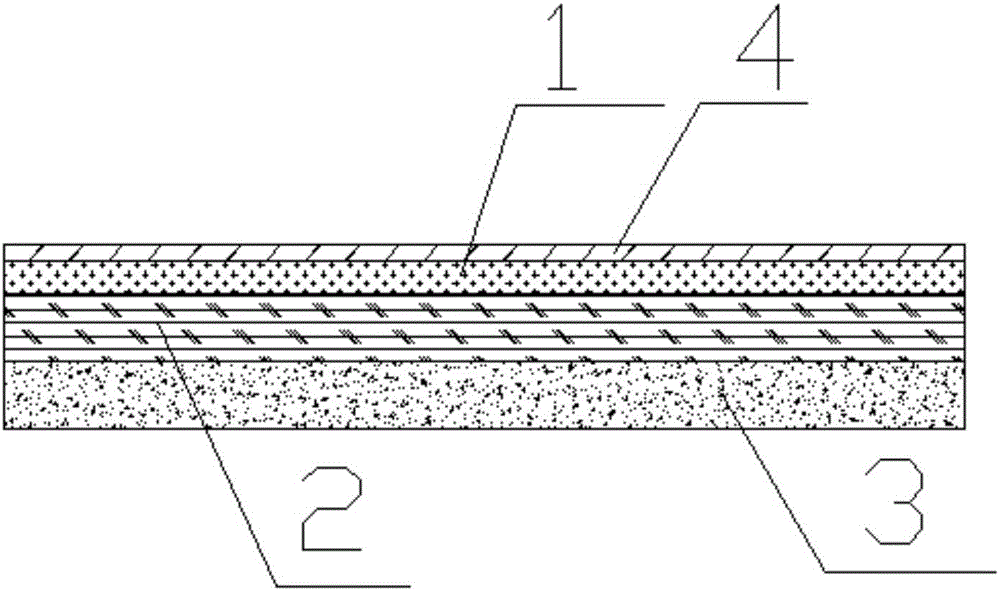

[0023] combine figure 1 , an antistatic and anti-electromagnetic radiation composite fabric, comprising an outer layer, a middle layer and an inner layer, the outer layer is an antistatic layer 1, the middle layer is an anti-electromagnetic radiation fiber layer 2, and the inner layer is an anti-electromagnetic radiation layer. The skin layer 3, the antistatic layer 1 is made of conductive fiber and cupro ammonia fiber blend, and the electromagnetic radiation prevention fiber layer 2 is made of metal wire blended yarn, and the metal wire blended wire is made of metal wire Blended with plant fibers at a weight ratio of 1:30, soaked in a collagen solution with a mass volume ratio of 4%, and then added a certain amount of complexing agent, soaked for 20 minutes, taken out, and dried. The skin-friendly layer 3 is made of natural cotton fiber and bamboo charcoal fiber blend.

[0024] In this embodiment, the surface of the antistatic layer 1 is coated with an antistatic coating 4 ....

Embodiment 2

[0031] combine figure 1, an antistatic and anti-electromagnetic radiation composite fabric, comprising an outer layer, a middle layer and an inner layer, the outer layer is an antistatic layer 1, the middle layer is an anti-electromagnetic radiation fiber layer 2, and the inner layer is an anti-electromagnetic radiation layer. The skin layer 3, the antistatic layer 1 is made of conductive fiber and cupro ammonia fiber blend, and the electromagnetic radiation prevention fiber layer 2 is made of metal wire blended yarn, and the metal wire blended wire is made of metal wire Blended with plant fibers at a weight ratio of 1:30, soaked in a collagen solution with a mass volume ratio of 5%, and then added a certain amount of complexing agent, soaked for 15 minutes, taken out, and dried. The skin-friendly layer 3 is made of natural cotton fiber and bamboo charcoal fiber blend.

[0032] In this embodiment, the surface of the antistatic layer 1 is coated with an antistatic coating 4 . ...

Embodiment 3

[0039] combine figure 1 , an antistatic and anti-electromagnetic radiation composite fabric, comprising an outer layer, a middle layer and an inner layer, the outer layer is an antistatic layer 1, the middle layer is an anti-electromagnetic radiation fiber layer 2, and the inner layer is an anti-electromagnetic radiation layer. The skin layer 3, the antistatic layer 1 is made of conductive fiber and cupro ammonia fiber blend, and the electromagnetic radiation prevention fiber layer 2 is made of metal wire blended yarn, and the metal wire blended wire is made of metal wire Blended with plant fibers at a weight ratio of 1:30, soaked in a collagen solution with a mass volume ratio of 4.5%, and then added a certain amount of complexing agent, soaked for 17.5 minutes, taken out, and dried. The skin-friendly layer 3 is made of natural cotton fiber and bamboo charcoal fiber blend.

[0040] In this embodiment, the surface of the antistatic layer 1 is coated with an antistatic coating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com