A kind of manufacturing method of thin gauge hot-rolled strip steel

A technology for hot-rolled strip steel and a manufacturing method, which is applied to manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of high power consumption and poor surface quality of the production line, and achieves increasing the number of rolling kilometers and improving the product quality. Effect of surface quality and extended roll change cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

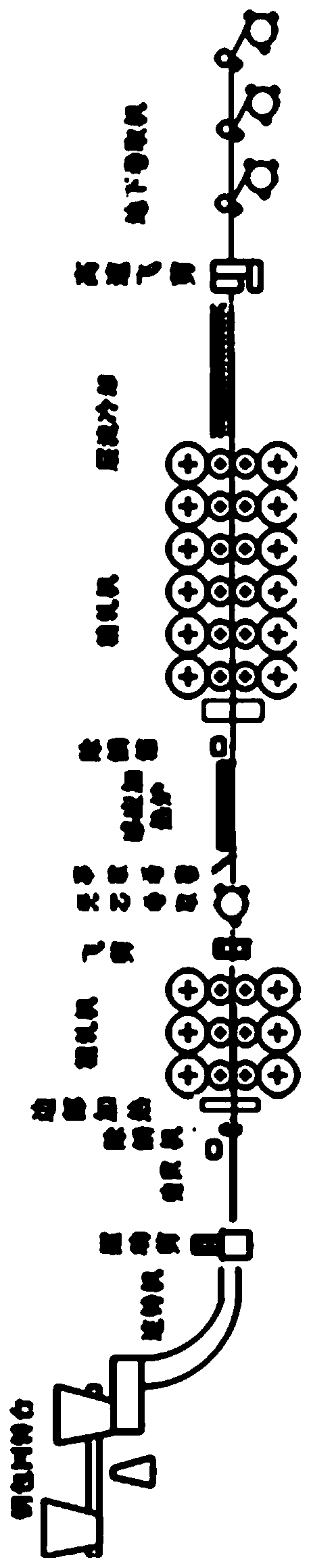

[0028] The process layout diagram of the thin-gauge steel strip production process of the present invention is as figure 1 shown. The specific implementation steps are as follows:

[0029] (1) The qualified molten steel produced in the steelmaking workshop is transported to the continuous casting workshop, and is hoisted by a crane to the ladle seat of the ladle turret, and the ladle turret rotates half a circle to the pouring position before pouring.

[0030] (2) After the casting starts, the casting speed of the continuous casting machine is gradually increased to 6.0m / min, the thickness of the continuous casting slab at the mold outlet is 90-110mm, the sector section is pressed down by 10mm, and the thickness of the casting slab at the exit of the continuous casting machine is 80-100mm. After the casting speed stabilizes, the surface temperature of the slab at the exit of the continuous casting machine is 1050-1150°C, and the temperature of the core of the slab is 1300-140...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com