Preparation method of porous FexCo3-xO4 nanocage, nanocage and application thereof

A nanocage and preparation process technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problem of catalyst deactivation and other problems, and achieve high activity, high specific surface area, and simple and easy preparation scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

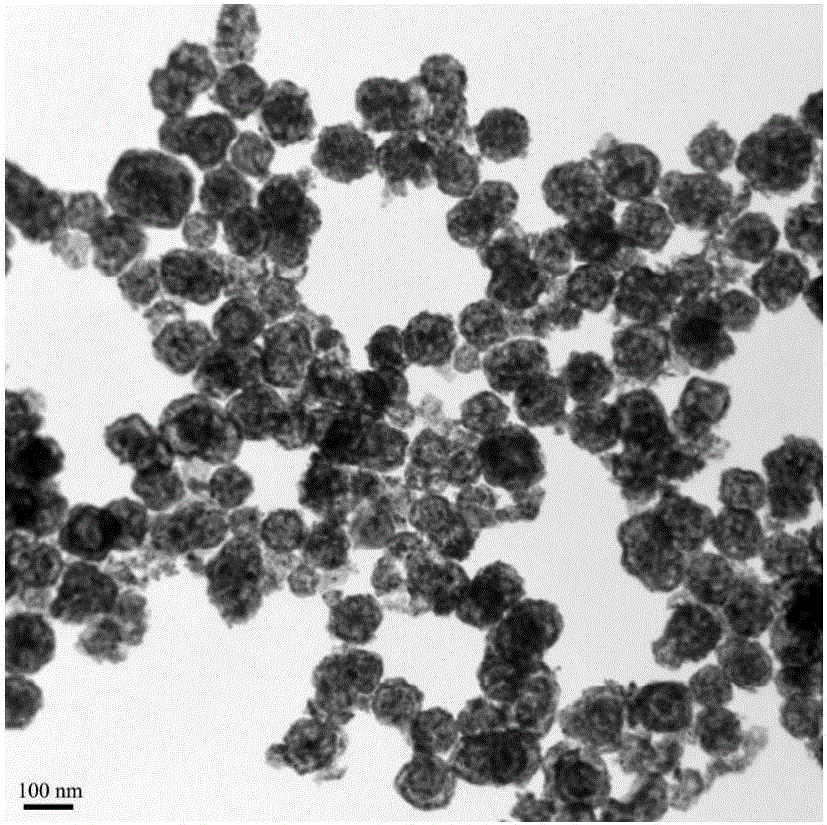

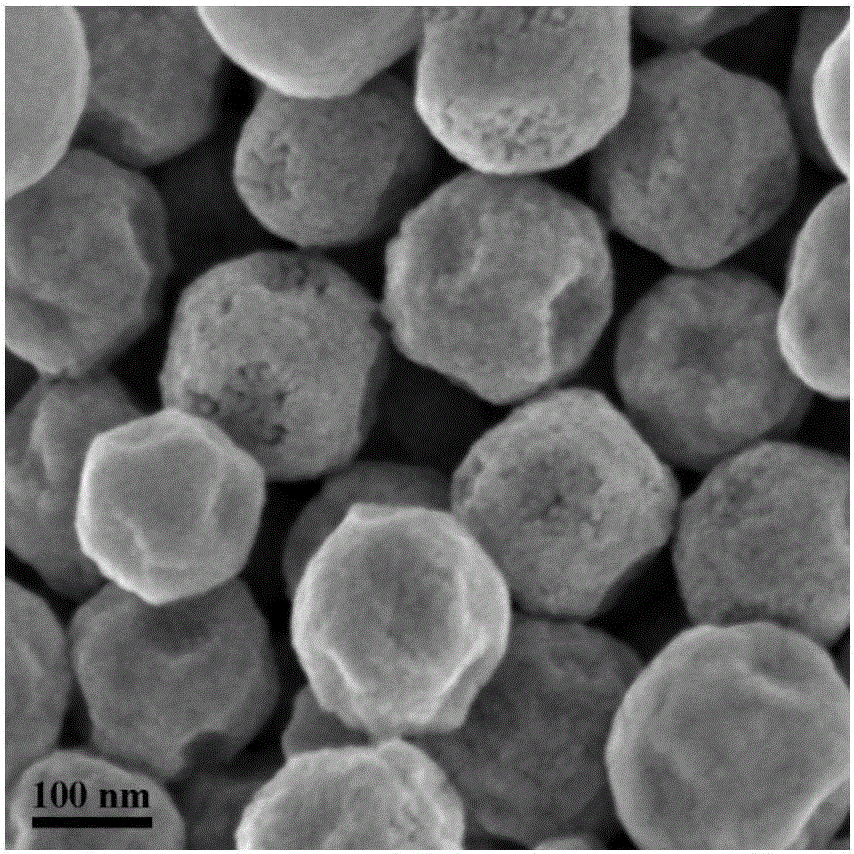

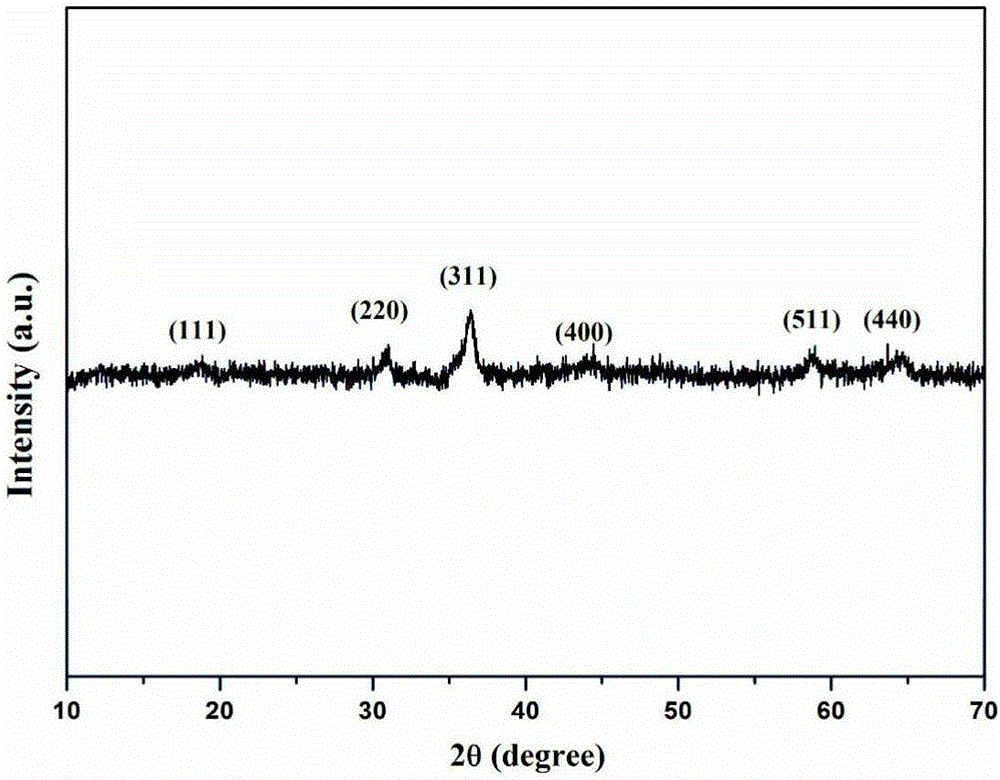

[0024] 0.0332g K 4 [Fe(CN) 6 ] was dissolved in 10ml of deionized water and stirred uniformly to obtain solution A, mixed and dissolved in 0.0262g of cobalt nitrate and 0.0179g of ferric chloride in 10ml of deionized water to obtain solution B, and 0.6g of PVP was added to solution B and stirred evenly. Solution A was slowly added dropwise to B and continued to stir for 30 min, aged at room temperature for 20 h. After centrifugation for 5min (8000r / min), the water-ethanol mixture (v / v=50 / 50) was washed three times, and dried at 60°C for 20h to obtain Fe 0.5 co 0.5 -Co PBAs nanosphere precursor. Fe can be obtained by calcining the above precursor at 500°C for 1 hour 0.8 co 2.2 o 4 nanocage. For the resulting Fe 0.8 co 2.2 o 4 Nanocages for Characterization: figure 1 is Fe 0.8 co 2.2 o 4 The TEM (transmission electron microscope) photo of the nanocage, it can be seen from the figure that the prepared nanocage is evenly dispersed, has a regular shape and is porous, ...

Embodiment 2

[0026] 0.0332g K 4 [Fe(CN) 6 ] was dissolved in 10ml of deionized water and stirred uniformly to obtain solution A, mixed and dissolved in 10ml of deionized water with 0.0315g of cobalt nitrate and 0.0144g of ferric chloride to obtain solution B, and 0.6g of PVP was added to solution B and stirred evenly. Solution A was slowly added dropwise to B and continued to stir for 30 min, aged at room temperature for 20 h. Separated for 5min (8000r / min), washed three times with water-ethanol mixture (v / v=50 / 50), dried at 60°C for 20h to obtain Fe 0.4 co 0.6 -Co PBAs nanosphere precursor. Fe can be obtained by calcining the above precursor at 500°C for 1 hour 0.7 co 2.3 o 4 nanocage.

Embodiment 3

[0028] 0.0332g K 4 [Fe(CN) 6 ] was dissolved in 10ml deionized water and stirred uniformly to obtain solution A, 0.0367g cobalt nitrate and 0.0108g ferric chloride were mixed and dissolved in 10ml deionized water to obtain solution B, and 0.6g PVP was added to solution B and stirred evenly. Solution A was slowly added dropwise to B and continued to stir for 30 min, aged at room temperature for 20 h. Centrifuge for 5min (8000r / min), wash with water-ethanol mixture (v / v=50 / 50) three times, dry at 60°C for 20h to obtain Fe 0.3 co 0.7 -Co PBAs nanosphere precursor. Fe can be obtained by calcining the above precursor at 500°C for 1 hour 0.5 co 2.5 o 4 nanocage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com